320, Seunggicheon-ro,

Namdong-gu, Incheon, Korea

Product

Premium Quality, Multifunctional Clad Metals

These composite metals are widely applied to automotive electrical and electronic components, EV components, secondary batteries, and mobile phones. These materials, which are fabricated by combining multiple metals, provide the electrical and physical properties that cannot be achieved with a single metal. Thus, these materials can be effectively used in designing multifunctional products and reducing production cost by replacing precious metals.Clad Metal can be defined as a metallurgical combination (bonding) of two or more metals under high pressure, resulting in a composite piece with the physical and electrical properties that cannot be achieved with a single metal or alloy. According to the types of bonding and materials, CSC’s clad metals are divided into an inlay clad, overlay clad, solder clad, contact tape clad, and composite clad.

Applications

Applications

- ∙ Battery tab, Bus-bar, Switch contact for automotive & home appliance, contact for electric parts.

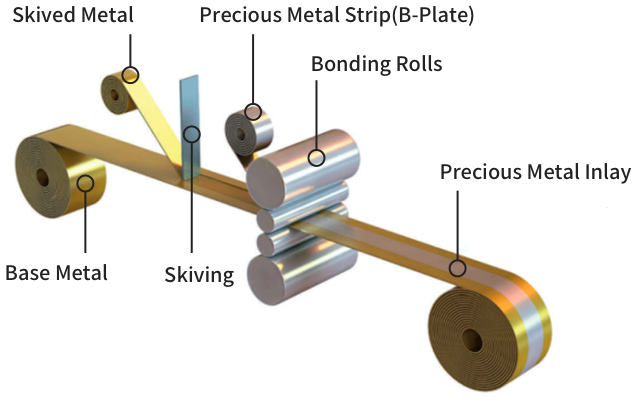

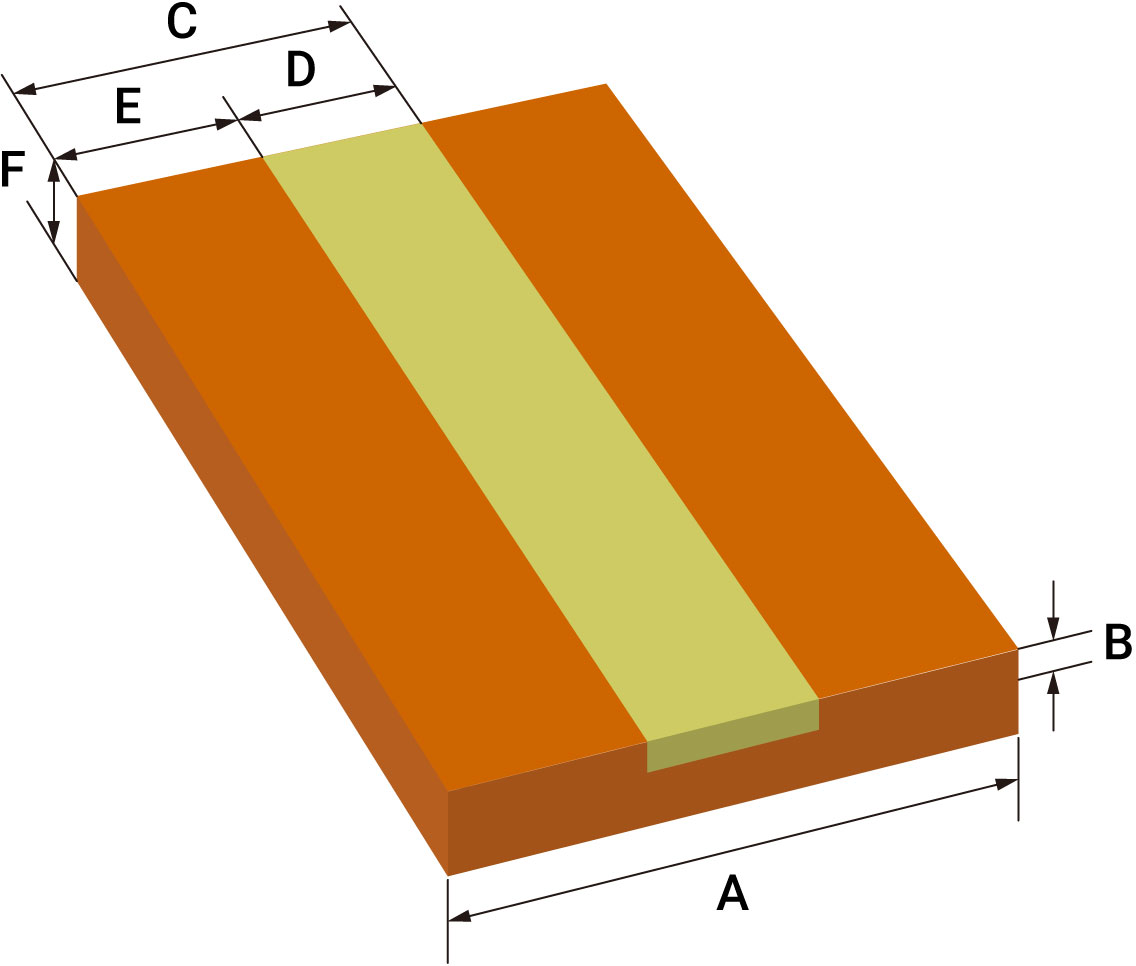

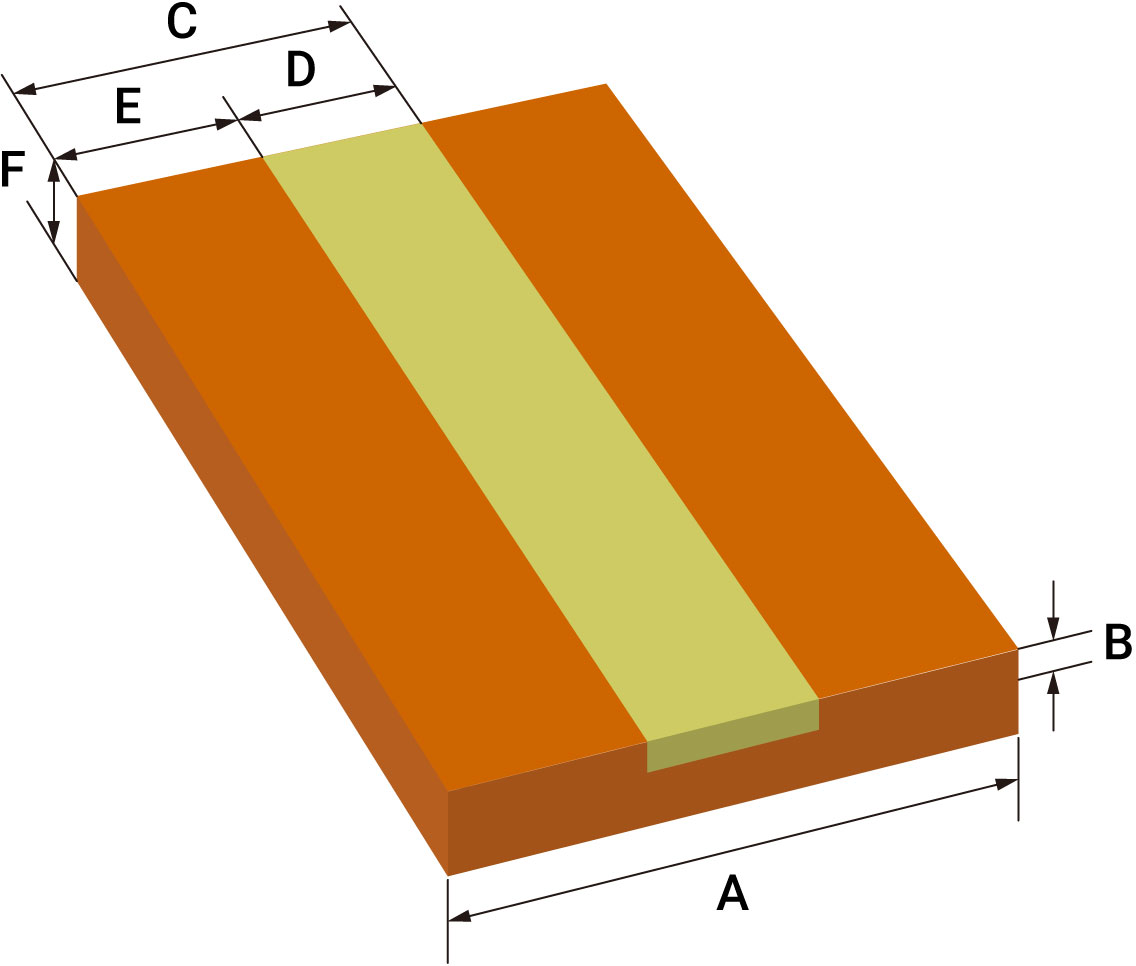

Inlay Clad

Inlay clad metals are products made by skiving at the base metal and inserting the contact material into a connection through the rolling process. It is possible to implement a property that cannot be achieved by coating. They are also cost effective in design because one only needs to insert the desired number of them into the parts they want.

Applications

Applications

- ∙ Small motor parts, Electric contact switch, home appliance switch and connectors

| Precious Metals | Base Metals |

|---|---|

|

Au99.99 Au75, Ag25 Au67, Ag33 Au58, Ag42 Au50, Ag50 Au69, Ag25, Pt6 Au10, Ag30, Pt10, Pd35, Cu-Zn Au70, Ag10, Pt5, Cu-Zn |

Nickel Silver Nickel Copper Brass Bronze Beryllium Copper Aluminum Copper Nickel MX96 MX215 Others |

|

Ag99.95 Ag92.5, Cu7.5 Ag90, Cu10 Ag75, Cu24.5, Ni0.5 Ag72, Cu28 Ag90, CdO10 Ag85, CdO15 Ag99, Cd1 Ag90, Ni10 Ag85, Ni15 |

|

|

Pd99.9 Ag90, Pd10 Ag70, Pd30 Ag50, Pd50 Others |

| Item | Min | Max |

|---|---|---|

| A. Strip Width | 6mm | 100mm |

| B. Clad Thickness | 0.002mm | F의 40% |

| C. Strip location | 1.2mm | A의 40% |

| D. Inlay Width | 1.2mm | A의 40% |

| E. Strip location | 0.0mm | A의 60% |

| F. Strip Thickness | 0.02mm | 1.2mm |

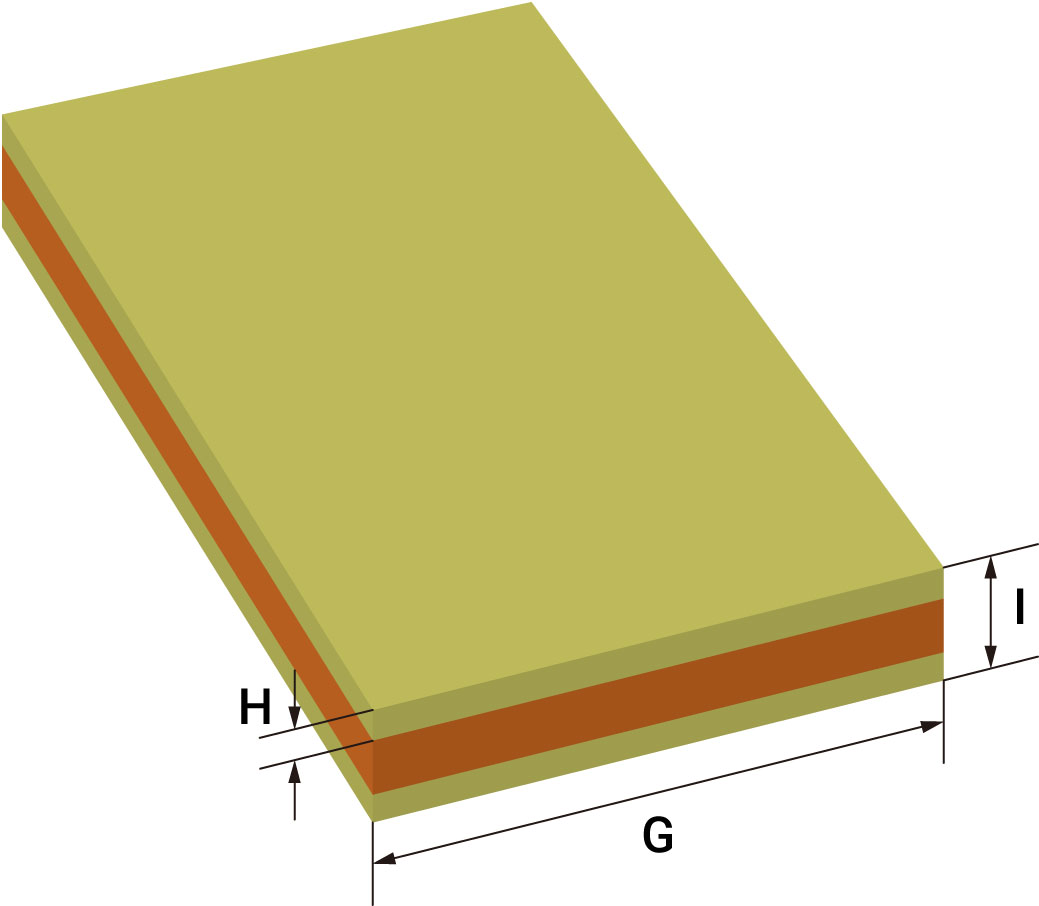

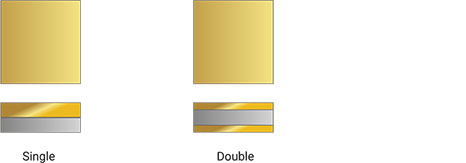

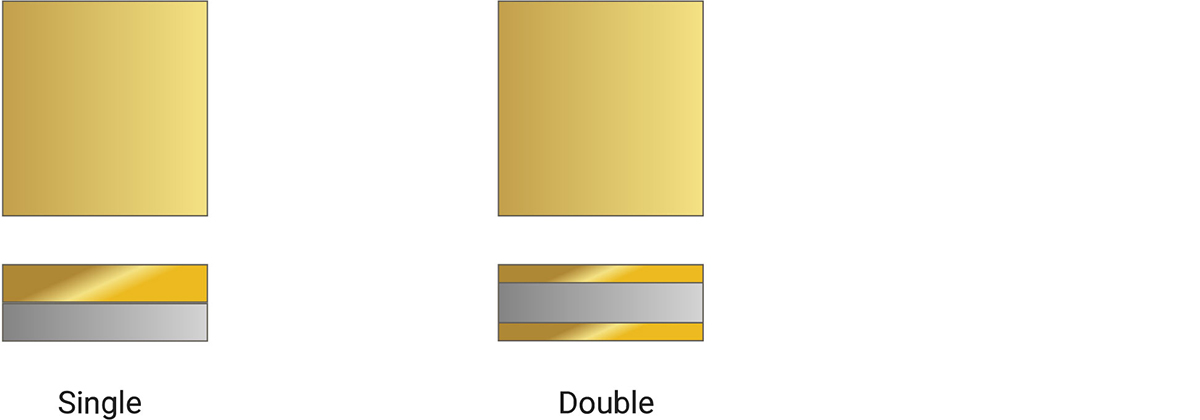

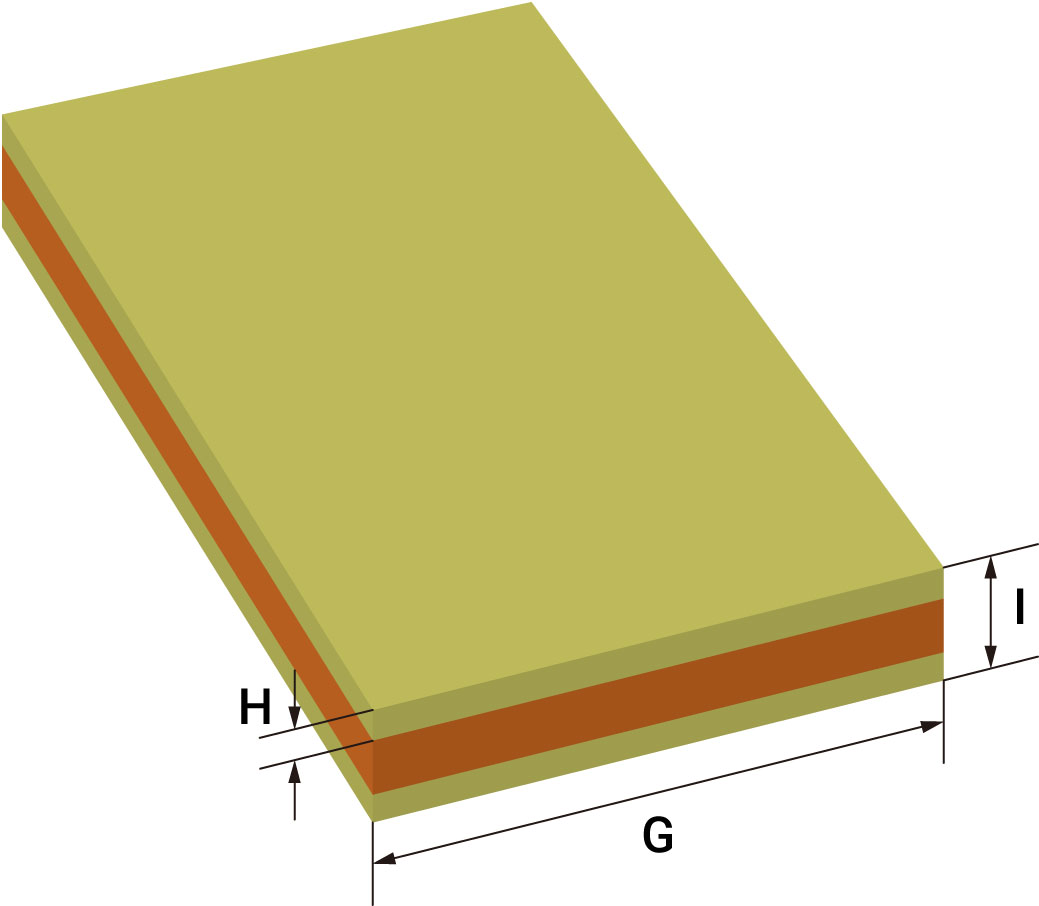

Overlay Clad

Overlay clad metals are defined as a combination of two or more metals of the same size. One-sided and two-sided cladding is already available at competitive prices. Also, the number of metals to be joined can be adjusted to meet the customers’ requirements.

Applications

Applications

- ∙ Battery tabs, Bus-bar / Electric contact switch, Volume switch, and various electrical contacts

| Precious Metals | Base Metals |

|---|---|

|

Au99.99 Au75, Ag25 Au67, Ag33 Au58, Ag42 Au50, Ag50 Au69, Ag25, Pt6 Au10, Ag30, Pt10, Pd35, Cu-Zn Au70, Ag10, Pt5, Cu-Zn |

Nickel Silver Nickel Copper Brass Bronze Beryllium Copper Aluminum Copper Nickel MX96 MX215 Others |

|

Ag99.95 Ag92.5, Cu7.5 Ag90, Cu10 Ag75, Cu24.5, Ni0.5 Ag72, Cu28 Ag90, CdO10 Ag85, CdO15 Ag99, Cd1 Ag90, Ni10 Ag85, Ni15 |

|

|

Pd99.9 Ag90, Pd10 Ag70, Pd30 Ag50, Pd50 Others |

| Item | Min | Max |

|---|---|---|

| G. Strip Width | 1.4mm | 200mm |

| H. Clad Thickness | 0.0001mm | I의 90% |

| I. Strip Thickness | 0.025mm | 1.2mm |

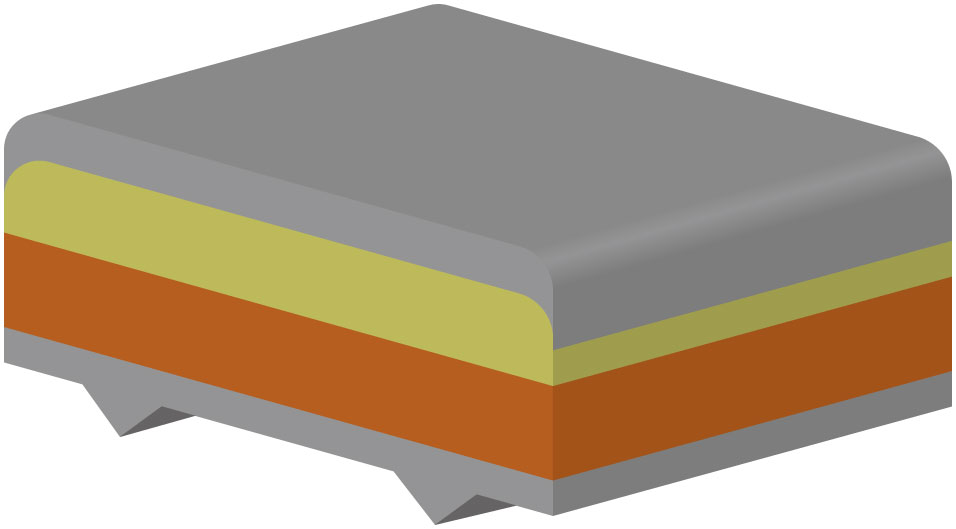

Bus-bar Clad (CCA)

By connecting both anodes and cathodes directly to the CCA bus, module circuits can be simplified, lightened and integrated

Applications

Applications

- ∙ Electric bus-bar

- ∙ Battery system bus-bar

- ∙ Electrodes for circuit

| Precious Metals | Base Metals |

|---|---|

| Copper | C1020 C1100 |

| Brass | C2600 C2680 |

| Bronze | C5191 C5210 |

| Beryllium Copper | C1700 C1720 |

| Aluminum | C1100 C5052 |

| Copper Nickel | C7060 C7150 |

| Item | Min | Max |

|---|---|---|

| G. Strip Width | 10mm | 200mm |

| H. Clad Thickness | I의 10% | I의 90% |

| I. Strip Thickness | 0.3mm | 5.0mm |

Contact Tape

This product is designed to suit the automatic production line by cladding some materials onto the back of high-function electrical contacts and forming them into the desired shape.

Applications

Applications

- ∙ Overload protection devices, Rivets, Buttons, Wires, Contacts, Weld, Relay

| Precious Metals | Base Metals |

|---|---|

|

Au99.99 Au75, Ag25 Au67, Ag33 Au58, Ag42 Au50, Ag50 Au69, Ag25, Pt6 Au10, Ag30, Pt10, Pd35, Cu-Zn Au70, Ag10, Pt5, Cu-Zn |

Nickel Silver Nickel Copper Brass Bronze Beryllium Copper Aluminum Copper Nickel MX96 MX215 Others |

|

Ag99.95 Ag92.5, Cu7.5 Ag90, Cu10 Ag75, Cu24.5, Ni0.5 Ag72, Cu28 Ag90, CdO10 Ag85, CdO15 Ag99, Cd1 Ag90, Ni10 Ag85, Ni15 |

|

|

Pd99.9 Ag90, Pd10 Ag70, Pd30 Ag50, Pd50 Others |

| Item | Min | Max |

|---|---|---|

| Strip Width | 2.0mm | 45mm |

| Clad Thickness | 0.003mm | 전체두께의 90% |

| Strip Thickness | 0.1mm | 1.2mm |

Composite Clad

This product is fabricated through a series of processes, such as Inlay, Overlay, Skiving, Plating, and Soldering, to best meet the customer’s needs.

Applications

Applications

- ∙ Volume switch, Connector, Solder connects

| Precious Metals | Base Metals |

|---|---|

|

Au99.99 Au75, Ag25 Au67, Ag33 Au58, Ag42 Au50, Ag50 Au69, Ag25, Pt6 Au10, Ag30, Pt10, Pd35, Cu-Zn Au70, Ag10, Pt5, Cu-Zn |

Nickel Silver Nickel Copper Brass Bronze Beryllium Copper Aluminum Copper Nickel MX96 MX215 Others |

|

Ag99.95 Ag92.5, Cu7.5 Ag90, Cu10 Ag75, Cu24.5, Ni0.5 Ag72, Cu28 Ag90, CdO10 Ag85, CdO15 Ag99, Cd1 Ag90, Ni10 Ag85, Ni15 |

|

|

Pd99.9 Ag90, Pd10 Ag70, Pd30 Ag50, Pd50 Others |

| Item | Min | Max |

|---|---|---|

| A. Strip Width | 6mm | 100mm |

| B. Clad Thickness | 0.002mm | F의 40% |

| C. Strip location | 1.2mm | A의 40% |

| D. Inlay Width | 1.2mm | A의 40% |

| E. Strip location | 0.0mm | A의 60% |

| F. Strip Thickness | 0.02mm | 1.2mm |

Shunt Resistor

It is mainly used for current detection in motor drive circuits, overcurrent protection of power supplies, and battery charge detection.

It enables miniaturization, high power, high precision, and high reliability for precise circuit control.

- ∙ Electronic Products, IT, EV, ESS

| Test Items | Performance Requirements | Test Methods |

|---|---|---|

| T.C.R |

400 uΩ ~ 5 mΩ : ± 75ppm/℃ 12W, 15W, 36W : ± 50ppm/℃ |

+25℃ ~ +125℃ |

| High temperature Exposure |

± 1.0% | 1000h at +125℃ |

| Thermal Shock | ± 1.0% | -55℃ to +125℃, 1000cycle, 30min at each extreme |

| Bias Humidity | ± 1.0% | +85℃, 85%RH, 1000h, 0.1×Rated Power |

| External Visual | No stab, discoloration, defective solder, terminal junction and bending |

Visual Inspection |

| Physical Dimension | Do the same in dimension data | 2D Measuring-set |

| Sensing terminal Junction Strength |

Under 20Kg, Loose sensing terminal | Junction Strength |

| Resistance to Solder Heat |

± 1.0% | 260±5℃ solder, 10±1sec dwell |

| Mechanical Shock | ± 1.0% | 100g’s for 6ms, 6axis @5times(Half-sine pulse) |

| Vibration | ± 1.0% | 5g’s, Frequency varied 10-2000Hz in 20min, 12cycle@3axis |

| Product | Dimension | ||||

|---|---|---|---|---|---|

| L | L1 | W | T | D | |

| 5216 | 52 | Custom made |

16 | 3.0 | Custom made |

| 6018 | 60 | 18 | 3.0 | ||

| 8420 | 84 | 20 | 3.0 | ||

| 8518 | 85 | 18 | 3.0 | ||

| 8536 | 85 | 36 | 3.0 | ||

| Size (mm) |

Resistance Range |

Resistance tolerance (%) |

Operation temp. Range (℃) |

Ambient Temperature (℃) |

|---|---|---|---|---|

| 5216 | 0.02 ~ 0.1 mΩ |

J : ± 5 | -55 ~ +125 | 70 |

| 6018 | ||||

| 8420 | ||||

| 8536 | ||||

| 8518 |