320, Seunggicheon-ro,

Namdong-gu, Incheon, Korea

Product

Metal Powders

Material Revolution, Metal Powders

It is a high functional complex powder part that can be applied to produce a wide range of future mechanical parts for various applications, such as automotive, AI, 5G, and 3D printing, and electronical raw material parts, such as MLCC, conductive paste, EMC parts, and film products. CSC’s constant innovation is directed towards people.

Metal powder is a fine powder that has high surface area for its volume,

and is available to acquire the characteristic of the material itself under high pressure.

Metal powder has various shapes, such as spherical, irregular, dendrite, flake, and square shapes, according to its manufacturing method.

It is available to produce various mechanical parts and materials across the industry more effectively and economically with the CSC metal powder.

- ∙ Copper and Copper alloyed powder :

- PM parts, Friction materials, Electrical contacts, Carbon brush and Diamond tools

- ∙ Iron alloyed powder :

- Magnetic powder core and PM parts

- ∙ AM metal powder :

- Bio-medical(Dental, others), Aircraft turbine and Thermal parts

- ∙ Silver powder and Coated powder :

- Conductive and shielding material

- ∙ Fine magnetic powder :

- Chip inductor

Powders

Copper Powders

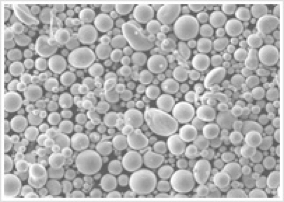

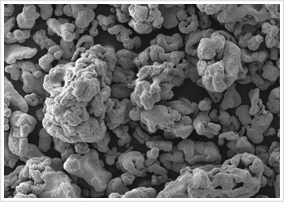

It is available to produce various shape such as high purity spherical, irregular, dendrite type customized part related to the customer’s needs.

Those various shape parts are applied to PM component, friction parts, electric contactors, and antibacterial products.

-

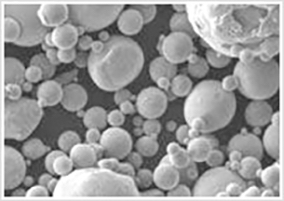

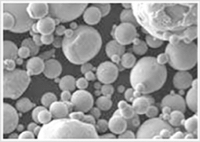

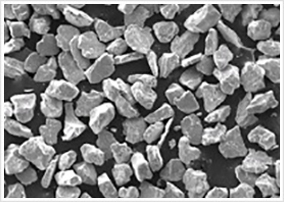

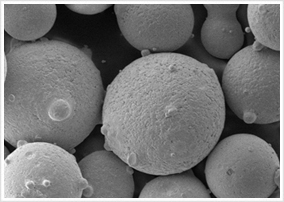

Atomized Copper

Atomized Copper

-

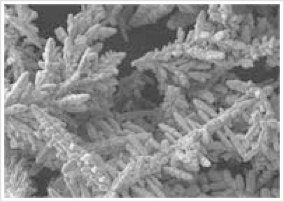

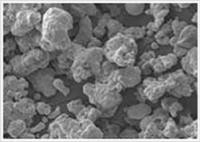

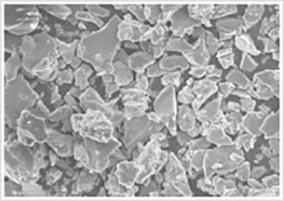

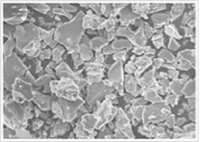

Electrolytic Copper

Electrolytic Copper

-

Fine Copper

Fine Copper

- ∙ Atomizing copper powder :

- Sintering parts, Friction materials, Electrical contacts and Catalysts

- ∙ Infiltration powder :

- Sintering parts

- ∙ Electrolytic copper powder :

- Sintering parts, Carbon brushes, Diamond tools and Catalysts

- ∙ Fine electrolytic copper powder and Fine copper powder :

- Conductive paste, Sheet, Additive material and other Conductive materials

| Product | Grade | Composition (%) | AD (g/cc) | FR (sec/50g) | H2Loss (%) | Mesh (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 | 80 | 100 | 140 | 200 | 325 | -325 | ||||||

| Atomized Copper | ACU-60 | Cu99.5min | 2.0~3.0 | 35max | 0.3max | 2max | 40min | Bal | 5max | |||

| ACU-140 | Cu99.5min | 2.8~3.8 | 45max | 0.3max | - | - | 5max | 10~20 | Bal | 40~60 | ||

| ACU-325 | Cu99.5min | 2.8~3.8 | NA | 0.3max | - | - | - | - | - | Bal | 65~85 | |

| Electrolytic Copper | ECU-1000 | Cu99.5min | 0.6~1.0 | NA | 0.5max | - | - | - | - | - | 5max | 95min |

| Fine Electrolytic Copper | ECU-010 | Cu99.5min | 0.5~0.8 | NA | 0.5max | Laser Particle Analysis (D50) 8.5~10.5㎛ | ||||||

| ECU-015 | Cu99.5min | 0.5~0.8 | NA | 0.5max | Laser Particle Analysis (D50) 15.0~18.0㎛ | |||||||

| Fine Copper | HACU-025 | Cu99.5min | 1.5~2.5 | NA | 0.6max | Laser Particle Analysis (D50) 2.5~3.0㎛ | ||||||

| HACU-065 | Cu99.5min | 2.0~3.0 | NA | 0.6max | Laser Particle Analysis (D50) 6.0~7.0㎛ | |||||||

Bronze Powders

CSC Bronze powder is produced by mixing or alloying depending on the application.

A sponge-type powder with excellent plasticity and sintering properties is applied to the oil soaked bearings and the spherical shape is applied to diamond tools.

-

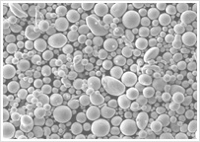

Premixed Bronze

Premixed Bronze

-

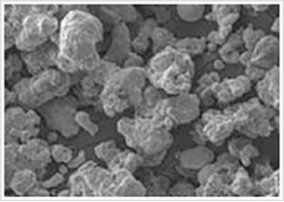

Alloyed Bronze

Alloyed Bronze

- ∙ Premixed bronze Powder :

- Oil-containing bearing and Sintering parts

- ∙ Alloyed bronze Powder :

- Diamond tools, Sintering parts, Filters and Dendrite fillers

| Product | Grade | Composition (%) | AD (g/cc) |

FR (sec/50g) |

Mesh(%) | |||

|---|---|---|---|---|---|---|---|---|

| 140 | 200 | 325 | -325 | |||||

| Premixed Bronze | KAB-23 | Cu90, Sn10 | 3.0~3.3 | 45max | 5max | 10~20 | 20~40 | 40~60 |

| KAB-23G | Cu89, Sn10, C1 | 3.0~3.3 | 45max | 5max | 10~20 | 20~40 | 40~60 | |

| Alloyed Bronze | PAB-10 | Cu90, Sn10 | 4.5~5.5 | NA | 1max | Bal | 90min | |

| PAB-15 | Cu85, Sn15 | 4.5~5.5 | NA | 1max | Bal | 90min | ||

| PAB-20 | Cu80, Sn20 | 4.5~5.5 | NA | 1max | Bal | 90min | ||

| PAB-33 | Cu67, Sn33 | 4.5~5.5 | NA | 1max | Bal | 90min | ||

Iron Alloyed Powders

Chang Sung’s alloyed powder is comprised of special characteristics such as high permeability and a low loss compared to other companies. We provide stable and regular quality assurance using our one-line system from development to manufacturing supported by our vast know-how gained through years of experience and production expertise.

-

Phosphorus Iron

Phosphorus Iron

-

High Flux

High Flux

-

Mega Flux

Mega Flux

-

Sendust

Sendust

-

G6

G6

-

M4

M4

- ∙ Soft magnetic powder :

- Magnetic powder core

- ∙ FeP powder :

- Sintering parts

- ∙ Tool Steel :

- 3D printed materials

| Product | Grade | Composition (%) | AD (g/cc) | Mesh (%) | Saturation Magnetization (Ms) | Coercivity (Hc) | |||

|---|---|---|---|---|---|---|---|---|---|

| 60 | 140 | 200 | 325 | emu/g | Oe | ||||

| Soft Magnet | MPP | Fe-Ni-Mo | 3.5~5.0 | 3max | Bal | 80-90 | 0.5~2 | ||

| High Flux | Fe-Ni | 3.5~5.0 | 3max | Bal | 150-160 | 2~5 | |||

| Mega Flux | Fe-Si | 3.5~5.0 | 3max | Bal | 190-200 | 5~8 | |||

| Sendust | Fe-Si-Al | 3.5~5.0 | 3max | Bal | 110-120 | 8~10 | |||

| Phosphorus Iron | PFP-015 | Fe 85, P15 | 2.8~3.2 | 0.1max | Bal | ||||

| Product | Grade | Composition(wt%) | AD (g/cc) |

TD (g/cc) |

F.R (sec/50g) |

Laser Particle Analysis(㎛) | Circularity | Hardness (HRC) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe | C | Mn | Si | Cr | Mo | V | W | O | D10 | D50 | D9O | |||||||

| Tool Steel |

G6 | Bal. | 0.4 | 0.3 | 2 | 9 | - | - | - | 0.03 | 4.19 | 4.9 | 14.5 | 56.9 | 80.6 | 112 | 0.95 | 50 |

| M4 | Bal. | 1.3 | 0.3 | 0.5 | 4 | 5 | 4 | 6 | 0.02 | 4.35 | 5 | 14.6 | 54.8 | 75.6 | 103 | 0.96 | 68 | |

Al Powders

CSC Aluminum powder is highly pure and fine-grained, which suits the needs of national defense and gunpowder industries and ensures stability with excellent membrane technology.

Also it is reliably supplied both domestically and abroad with its production system using specially designed protective equipment.

-

Aluminum

Aluminum

- ∙ Refractory material, Friction material, Sintering material, Propellant and Explosive material

Low Melting Powders

CSC tin powder is applied to the friction materials, diamond tools, and painting material.

Also we can provide a customized powder to meet the customer’s requirement.

-

Tin

Tin

- ∙ Friction material and Diamond tools

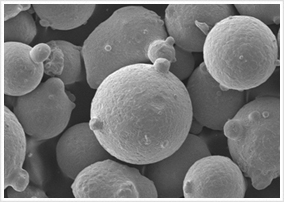

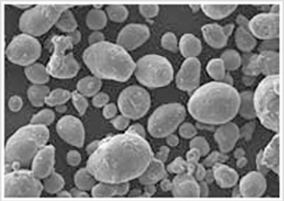

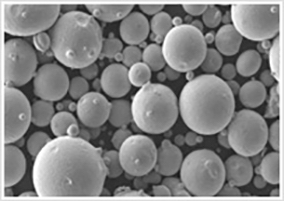

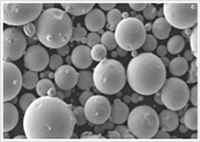

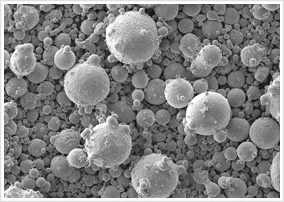

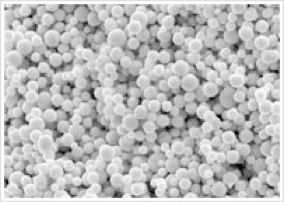

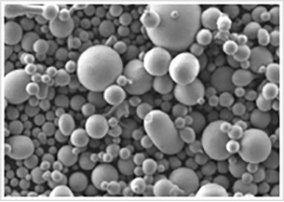

AM Powders

CSC AM powder is the key material for 3D printing developed in cooperation with the domestic companies and institutions.

Our atomizing and sieving technology has enabled the control of the shape, spherical, flow rate, size, and uniform contents.

-

Co-Cr-Mo

Co-Cr-Mo

-

Cu

Cu

-

Al Based Alloy

Al Based Alloy

-

Ni Based Alloy

Ni Based Alloy

- ∙ For 3D printing (additive manufacturing)

- - Cobalt alloy :

- Biomedical (Dental)

- - Copper alloy :

- Heat exchanger and Jewelry

- - Al alloy :

- UAM Lightweight materials, Automotive Lightweight materials

- - Nickel alloy :

- Aerospace (Turbine)

| Product | Grade | Type | AD (g/cc) |

TD (g/cc) |

O2Cont. (wt%) |

Laser Particle Size(μm) | ||

|---|---|---|---|---|---|---|---|---|

| D10 | D50 | D90 | ||||||

| Metal Powders for 3D Printing |

Co Based Alloy | PBF | 4.0~5.0 | 4.8~5.8 | 0.1max | 15~25 | 25~35 | 40~50 |

| DED | 0.03max | 35~55 | 50~70 | 90~110 | ||||

| Cu Based Alloy | PBF | 4.5~5.5 | 5.0~6.0 | 0.1max | 15~25 | 25~35 | 40~50 | |

| DED | 0.05max | 35~55 | 50~70 | 90~110 | ||||

| Al Based Alloy | PBF | 1.0~1.5 | 1.5~2.0 | 0.05max | 15~25 | 25~35 | 40~50 | |

| DED | 0.02max | 35~55 | 50~70 | 90~110 | ||||

| Ni Based Alloy | PBF | 4.0~5.0 | 5.0~5.5 | 0.05max | 15~25 | 25~35 | 40~50 | |

| DED | 0.02max | 35~55 | 50~70 | 90~110 | ||||

Functional Powders

Silver Powders

CSC silver powder is used as a filler for conductive pastes and provides suitable sintering properties and electrical conductivity for various substrates.

-

Spherical Silver

Spherical Silver

-

Fine Silver

Fine Silver

-

Flake Silver

Flake Silver

- ∙ Spherical silver powder and Fine sliver powder :

- Conductive material, Thick film, Conductive pastes, Thermally conductive material, and Electrical contacts

- ∙ Flake silver powder :

- Shielding material, Conductive pastes, and Thin conductive films

| Product | Grade | Shape | AD (g/cc) |

TD (g/cc) |

BET (㎡/g) |

538℃ Loss (Wt%) |

Laser Particle Size(㎛) | ||

|---|---|---|---|---|---|---|---|---|---|

| D10 | D50 | D90 | |||||||

| Spherical Silver | HAG-100S | Spherical | 2.3 | 3.5 | - | 0.3 | 0.5 | 1 | 1.5 |

| HAG-150S | 2.4 | 4 | 0.6 | 0.2 | 1 | 1.8 | 3 | ||

| HAG-250S | 3 | 4.2 | 0.5 | 0.2 | 1.7 | 2.6 | 4.5 | ||

| Fine Silver | HAG-800 | Irregular | 2.8 | 3.7 | 1 | 0.1 | 4.5 | 10 | 20 |

| Flake Silver | FAG-80A | Flake | 0.8 | 1.5 | 2.5 | 1 | 4 | 10 | 20 |

Coated Powders

CSC has low-density core powder production technology to produce high-quality coating powder and manufacturing facilities for wet and dry coating. Thus, it is possible to control the shape and size of core powder and the content of Ag (%) as a coating layer.

We can meet the increasing demand for core powder with various qualities, which are increasingly used in high-functional and eco-friendly electronic devices.

Also for the PM components, it is available to make special sintered parts by the coated powder with uniformity thickness.

-

Ag Coated Cu(Dendrite)

Ag Coated Cu(Dendrite)

-

Ag Coated Ni

Ag Coated Ni

-

TCF-50A20N

TCF-50A20N

- ∙ Conductive pastes and Inks, Conductive sheets, Conductive adhesives and tapes and ACF.

| Product | Grade | Shape | Content (wt%) |

AD (g/cc) |

TD (g/cc) |

Laser Particle Size(㎛) | ||

|---|---|---|---|---|---|---|---|---|

| D10 | D50 | D90 | ||||||

| Silver/Copper | TSC-10D07 | Dendrite | Ag 7 | 0.7 | 1.2 | 4 | 9 | 15 |

| TSC-15D03 | Ag 3 | 0.8 | 1.3 | 6 | 16 | 25 | ||

| Silver/Nickel | TSN-15F20 | Flake | Ag 20 | 1.5 | 2 | 8 | 15 | 25 |

| Product | Grade | Composition (%) | AD (g/cc) |

FR (sec/50g) |

Mesh (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 80 | 100 | 140 | 200 | 325 | -325 | |||||

| Copper/Iron | TCF-50A20N | Cu20, Fe80 | 2.1~2.4 | ≤40 | 2max | 10max | 15~35 | 20~40 | 15~35 | 15~35 |

Fine Magnetic Powder

CSC fine magnetic powder is used as a raw material for the chip inductors.

The higher magnetic saturation point and finer powder size are required to respond to the shift toward high-current and high-frequency components.

CSC provides an optimal powder through its powder composition design, heat treatment, and insulation technology.

-

Amorphous

Amorphous

-

Crystalline

Crystalline

- ∙ Power inductor and Chip inductor

| Product | Model | Composition | Powder Properties | Partide Size Distribution |

Powder Magnetic Property | ||

|---|---|---|---|---|---|---|---|

| AD (g/cm3) | TD (g/cm3) | D50 (㎛) | MS (emu/g) | Hc (Oe) | |||

| Crystalline | FSC-82-15 | Fe-Si-Cr | 3.0-4.0 | 4.0-5.0 | 13-17 | 160-175 | 3-5 |

| FSC-82-20 | 3.2-4.2 | 4.0-5.0 | 18-22 | ||||

| FSC-82-25 | 3.5-4.5 | 4.0-5.0 | 23-29 | ||||

| Amorphous | AFSC-15 | Fe-Si-Cr-B-C | 3.5-4.5 | 4.0-5.0 | 13-17 | 140-160 | 0.5-1.5 |

| AFSC-20 | 3.5-4.5 | 4.0-5.0 | 18-22 | ||||

| AFSC-25 | 3.5-4.5 | 4.0-5.0 | 23-29 | ||||

※CSC can provide an insulation powder.