仁川广域市南洞区升基川路320

320 (南村洞620-8)

Premium Quality, Multifunctional Clad Metals

是一种广泛应用于汽车电装、电动汽车零部件、二次电池和手机的复合型金属。 通过组合两种或多种金属,具有单一金属难以生产的电学和物理性能和功能。在设计多功能产品和降低贵金属成本方面效果突出。复合金属带是将具有不同特性的两种以上金属在高压下进行热处理,并使两种金属结合的复合金属。 C复合金属带可根据结合类型和材料分为Inlay、Overlay、Contact Tape、Composite Clad 等类型。

应用领域

应用领域

- ∙ Battery Tab, Bus-bar, 电装接点 /家电产品开关、各种电器接点用配件

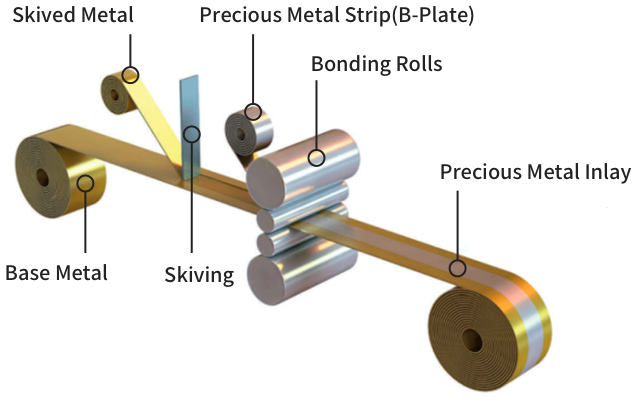

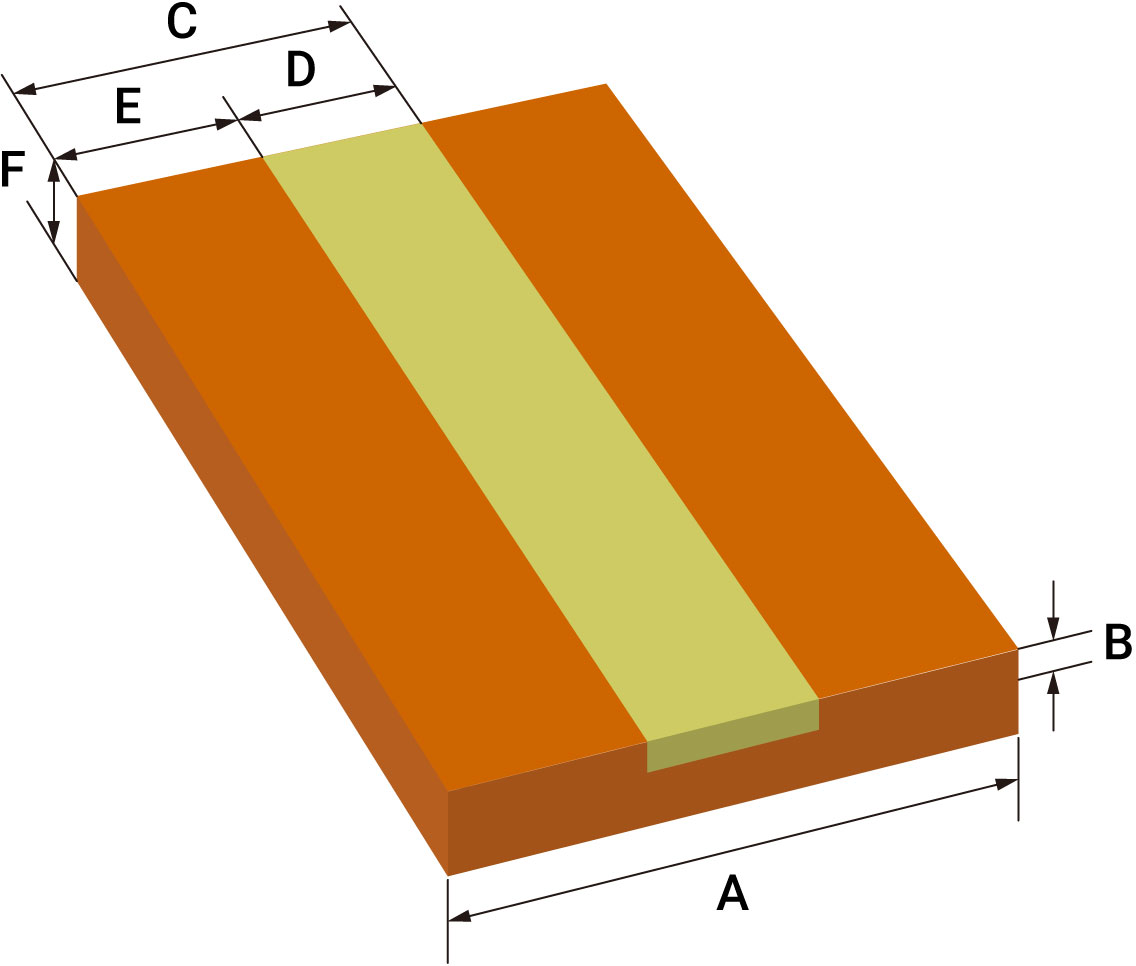

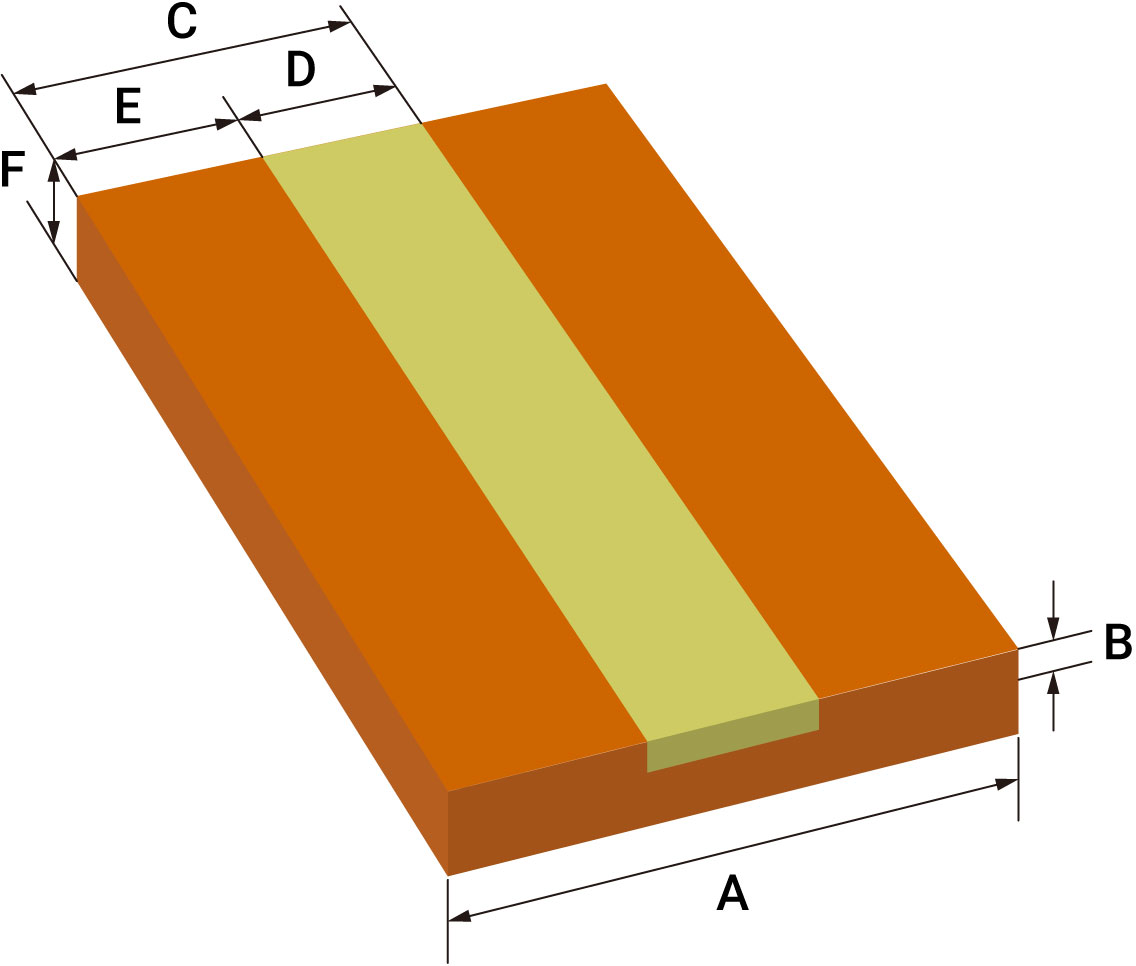

Inlay Clad

Inlay Clad是在母材料上挖槽, 插入接点材料,通过压延过程进行接合的产品。它可实现无法用镀金生成的合金设计和特性设计,并通过在所需部位插入所需数量的贵金属,有助于降低成本。

应用领域

应用领域

- ∙ 小型电机配件、电装接点开关、家用电器开关、连接器

| Precious Metals | Base Metals |

|---|---|

|

Au99.99 Au75, Ag25 Au67, Ag33 Au58, Ag42 Au50, Ag50 Au69, Ag25, Pt6 Au10, Ag30, Pt10, Pd35, Cu-Zn Au70, Ag10, Pt5, Cu-Zn |

Nickel Silver Nickel Copper Brass Bronze Beryllium Copper Aluminum Copper Nickel MX96 MX215 Others |

|

Ag99.95 Ag92.5, Cu7.5 Ag90, Cu10 Ag75, Cu24.5, Ni0.5 Ag72, Cu28 Ag90, CdO10 Ag85, CdO15 Ag99, Cd1 Ag90, Ni10 Ag85, Ni15 |

|

|

Pd99.9 Ag90, Pd10 Ag70, Pd30 Ag50, Pd50 Others |

| Item | Min | Max |

|---|---|---|

| A. Strip Width | 6mm | 100mm |

| B. Clad Thickness | 0.002mm | F의 40% |

| C. Strip location | 1.2mm | A의 40% |

| D. Inlay Width | 1.2mm | A의 40% |

| E. Strip location | 0.0mm | A의 60% |

| F. Strip Thickness | 0.02mm | 1.2mm |

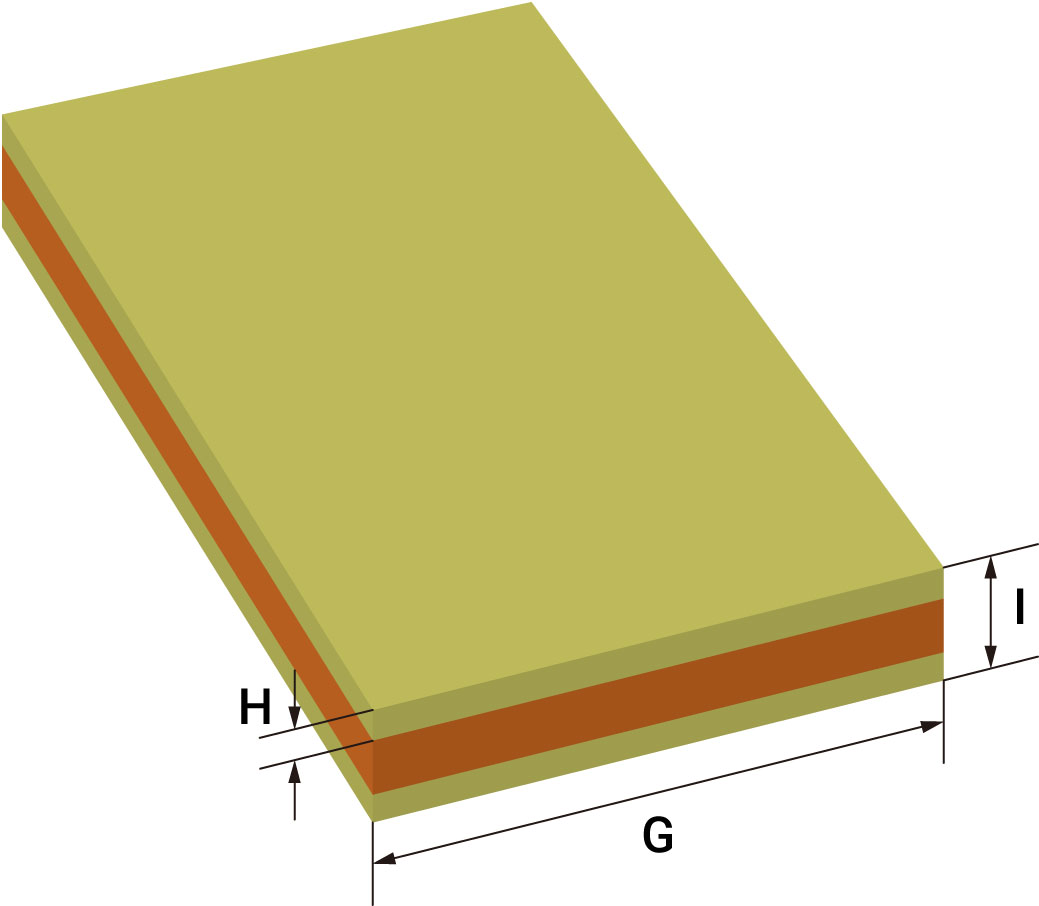

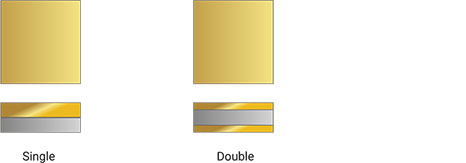

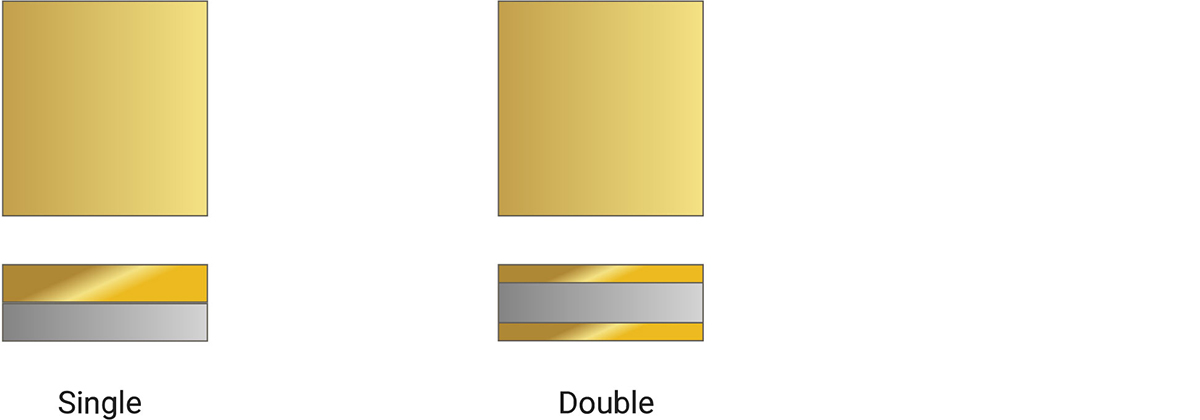

Overlay Clad

Overlay Clad是将母材料和接点材料相互叠加后,通过压延过程进行结合的产品。它可根据客户要求叠加多种金属进行结合。

应用领域

应用领域

- ∙ Battery Tab, Bus-bar, tact/音量开关及各种电器接点类

| Precious Metals | Base Metals |

|---|---|

|

Au99.99 Au75, Ag25 Au67, Ag33 Au58, Ag42 Au50, Ag50 Au69, Ag25, Pt6 Au10, Ag30, Pt10, Pd35, Cu-Zn Au70, Ag10, Pt5, Cu-Zn |

Nickel Silver Nickel Copper Brass Bronze Beryllium Copper Aluminum Copper Nickel MX96 MX215 Others |

|

Ag99.95 Ag92.5, Cu7.5 Ag90, Cu10 Ag75, Cu24.5, Ni0.5 Ag72, Cu28 Ag90, CdO10 Ag85, CdO15 Ag99, Cd1 Ag90, Ni10 Ag85, Ni15 |

|

|

Pd99.9 Ag90, Pd10 Ag70, Pd30 Ag50, Pd50 Others |

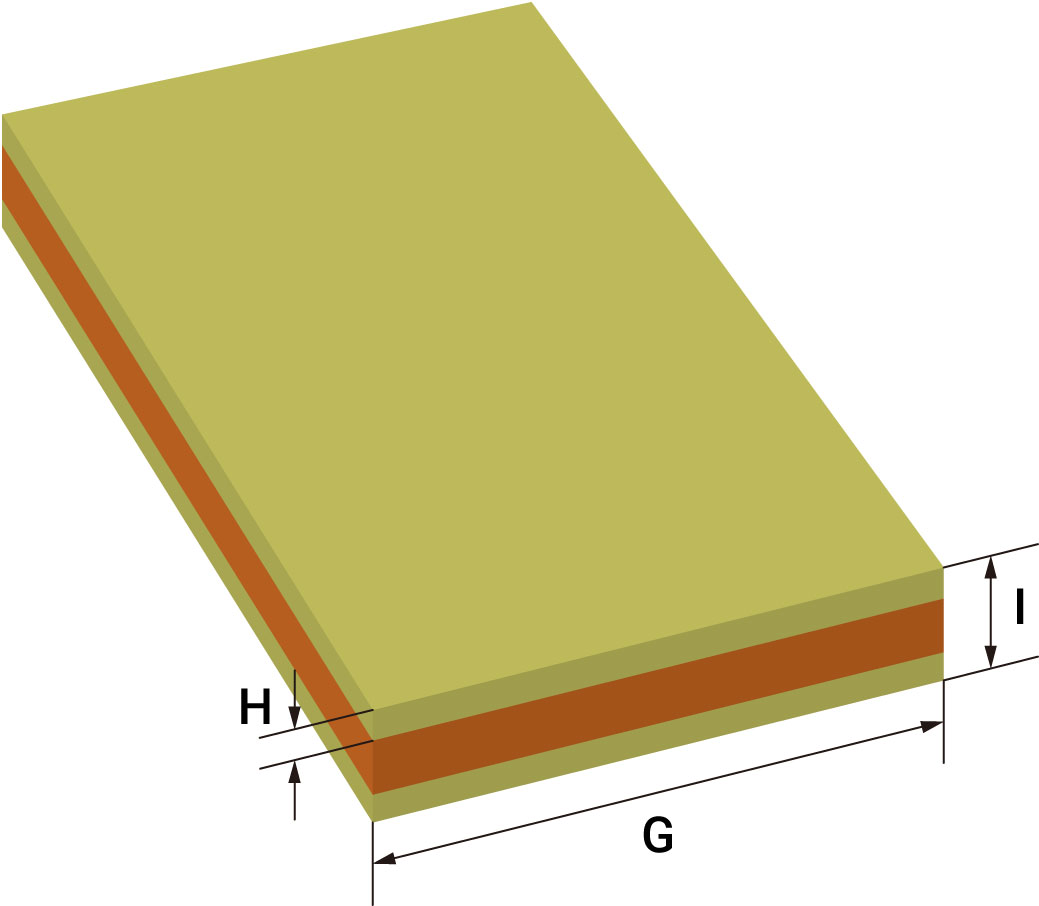

| Item | Min | Max |

|---|---|---|

| G. Strip Width | 1.4mm | 200mm |

| H. Clad Thickness | 0.0001mm | I의 90% |

| I. Strip Thickness | 0.025mm | 1.2mm |

Bus-bar Clad (CCA)

用一个导电体(CCA)连接正极和负极,可实现模块电路的简单化、轻量化、集成化。

应用领域

应用领域

- ∙ 电动导电体

- ∙ 电池系统导电体

- ∙ 电路用电极

| Precious Metals | Base Metals |

|---|---|

| Copper | C1020 C1100 |

| Brass | C2600 C2680 |

| Bronze | C5191 C5210 |

| Beryllium Copper | C1700 C1720 |

| Aluminum | C1100 C5052 |

| Copper Nickel | C7060 C7150 |

| Item | Min | Max |

|---|---|---|

| G. Strip Width | 10mm | 200mm |

| H. Clad Thickness | I의 10% | I의 90% |

| I. Strip Thickness | 0.3mm | 5.0mm |

Contact Tape

为便于高功能性电点焊接,结合特定材料,塑造形象,适合自动化生产线的产品。

应用领域

应用领域

- ∙ 防超负荷器, Rivets, Buttons, Wires Weld, Contacts,Relay

| Precious Metals | Base Metals |

|---|---|

|

Au99.99 Au75, Ag25 Au67, Ag33 Au58, Ag42 Au50, Ag50 Au69, Ag25, Pt6 Au10, Ag30, Pt10, Pd35, Cu-Zn Au70, Ag10, Pt5, Cu-Zn |

Nickel Silver Nickel Copper Brass Bronze Beryllium Copper Aluminum Copper Nickel MX96 MX215 Others |

|

Ag99.95 Ag92.5, Cu7.5 Ag90, Cu10 Ag75, Cu24.5, Ni0.5 Ag72, Cu28 Ag90, CdO10 Ag85, CdO15 Ag99, Cd1 Ag90, Ni10 Ag85, Ni15 |

|

|

Pd99.9 Ag90, Pd10 Ag70, Pd30 Ag50, Pd50 Others |

| Item | Min | Max |

|---|---|---|

| Strip Width | 2.0mm | 45mm |

| Clad Thickness | 0.003mm | 전체두께의 90% |

| Strip Thickness | 0.1mm | 1.2mm |

Composite Clad

Composite Clad是采用Inlay、Overlay、Skiving、Plating、Soldering等制成的复合型产品。我们可根据客户的需求,提供针对型的产品。

应用领域

应用领域

- ∙ 音量开关, 连接器 ,电器接点类

| Precious Metals | Base Metals |

|---|---|

|

Au99.99 Au75, Ag25 Au67, Ag33 Au58, Ag42 Au50, Ag50 Au69, Ag25, Pt6 Au10, Ag30, Pt10, Pd35, Cu-Zn Au70, Ag10, Pt5, Cu-Zn |

Nickel Silver Nickel Copper Brass Bronze Beryllium Copper Aluminum Copper Nickel MX96 MX215 Others |

|

Ag99.95 Ag92.5, Cu7.5 Ag90, Cu10 Ag75, Cu24.5, Ni0.5 Ag72, Cu28 Ag90, CdO10 Ag85, CdO15 Ag99, Cd1 Ag90, Ni10 Ag85, Ni15 |

|

|

Pd99.9 Ag90, Pd10 Ag70, Pd30 Ag50, Pd50 Others |

| Item | Min | Max |

|---|---|---|

| A. Strip Width | 6mm | 100mm |

| B. Clad Thickness | 0.002mm | F의 40% |

| C. Strip location | 1.2mm | A의 40% |

| D. Inlay Width | 1.2mm | A의 40% |

| E. Strip location | 0.0mm | A의 60% |

| F. Strip Thickness | 0.02mm | 1.2mm |

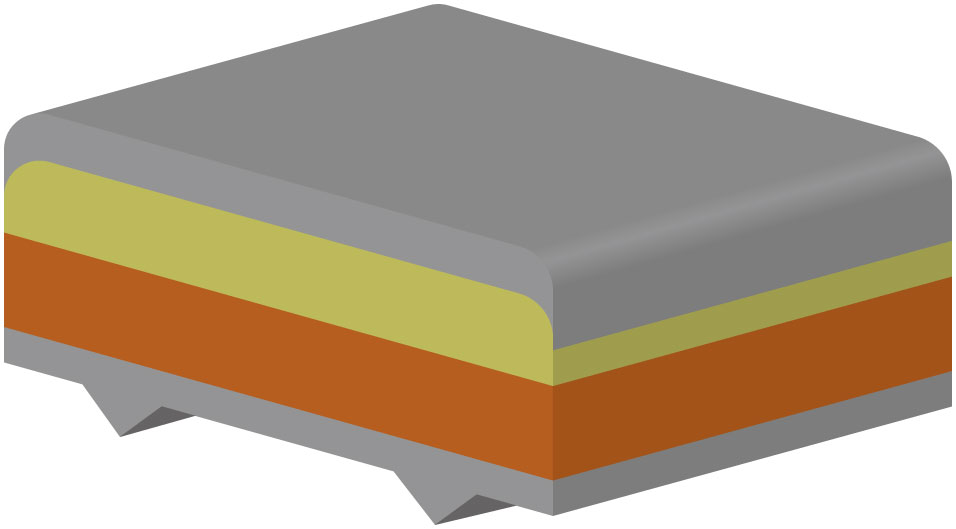

Shunt Resistor

用于电流检测,主要应用于电机驱动电路和电源的过电流保护、 电池剩余电量检测等领域。

实现小型化、高功率化、高精度、高可靠性等精密电路控制。

- ∙ Electronic Products, IT, EV, ESS

| Test Items | Performance Requirements | Test Methods |

|---|---|---|

| T.C.R |

400 uΩ ~ 5 mΩ : ± 75ppm/℃ 12W, 15W, 36W : ± 50ppm/℃ |

+25℃ ~ +125℃ |

| High temperature Exposure |

± 1.0% | 1000h at +125℃ |

| Thermal Shock | ± 1.0% | -55℃ to +125℃, 1000cycle, 30min at each extreme |

| Bias Humidity | ± 1.0% | +85℃, 85%RH, 1000h, 0.1×Rated Power |

| External Visual | No stab, discoloration, defective solder, terminal junction and bending |

Visual Inspection |

| Physical Dimension | Do the same in dimension data | 2D Measuring-set |

| Sensing terminal Junction Strength |

Under 20Kg, Loose sensing terminal | Junction Strength |

| Resistance to Solder Heat |

± 1.0% | 260±5℃ solder, 10±1sec dwell |

| Mechanical Shock | ± 1.0% | 100g’s for 6ms, 6axis @5times(Half-sine pulse) |

| Vibration | ± 1.0% | 5g’s, Frequency varied 10-2000Hz in 20min, 12cycle@3axis |

| Product | Dimension | ||||

|---|---|---|---|---|---|

| L | L1 | W | T | D | |

| 5216 | 52 | Custom made |

16 | 3.0 | Custom made |

| 6018 | 60 | 18 | 3.0 | ||

| 8420 | 84 | 20 | 3.0 | ||

| 8518 | 85 | 18 | 3.0 | ||

| 8536 | 85 | 36 | 3.0 | ||

| Size (mm) |

Resistance Range |

Resistance tolerance (%) |

Operation temp. Range (℃) |

Ambient Temperature (℃) |

|---|---|---|---|---|

| 5216 | 0.02 ~ 0.1 mΩ |

J : ± 5 | -55 ~ +125 | 70 |

| 6018 | ||||

| 8420 | ||||

| 8536 | ||||

| 8518 |