仁川广域市南洞区升基川路320

320 (南村洞620-8)

Global No.1, Soft Magnetic Powder Cores

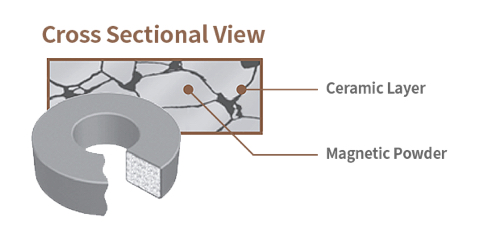

昌星全球第一的磁粉芯是用于汽车,服务器, 光伏 ,通讯设备等电力转换装置的核心材料,可提高所有电子设备的能源利用率。昌星用科技打造可持续的未来。采用合金粉末制成的磁粉芯在高频率下损耗低,并且由于磁粉芯内部均匀地分布着开气隙,所以磁通量几乎不会泄露,而且在高DC电流下也不易饱和。

应用领域

应用领域

- ∙ 汽车,服务器,太阳能,UPS,通讯设备,音响设备,测量设备等的电力转换设备。

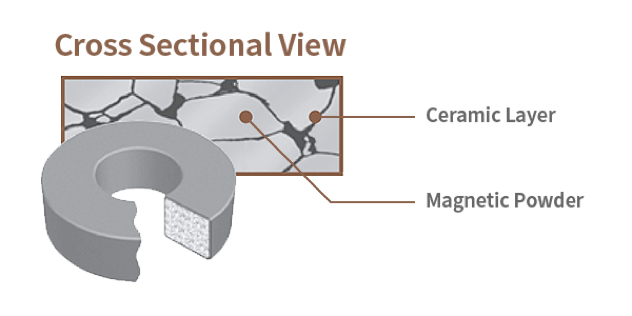

钛金系列

铁镍钛金

钛金系列的高磁通铁镍磁芯(High Flux GT)是通过CSC创新制造工艺研发的全球性能最优秀的高磁通铁镍(High Flux)材料,专门用于需要高效率的电动汽车车载充电器(OBC),服务器电源,通信电源等设备。钛金系列的高磁通铁镍磁芯 (High Flux GT)作为CSC的伟大之作,与传统的高磁通铁镍相比, 可提供更高的直流叠加特性(DC Bias)的同时,在200kHz下可将磁芯损耗降低至25%左右,帮助用户优化PFC和输出电感的设计。

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||

| 26u | 060u | 125u | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CH097GT | 14 | 32 | 67 | 2.18 | 0.095 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| CH102GT | 14 | 32 | 67 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| CH112GT | 11 | 26 | 54 | 2.69 | 0.091 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| CH127GT | 12 | 27 | 56 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| CH147GT | 14 | 32 | 67 | 3.63 | 0.154 | 14.7 | 8.9 | 5.6 | 15.5 | 8.2 | 6.4 |

| CH166GT | 15 | 35 | 73 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| CH172GT | 19 | 43 | 90 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| CH203GT | 14 | 32 | 67 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| CH229GT | 19 | 43 | 90 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| CH234GT | 22 | 51 | 106 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CH252GT | 27 | 62 | 130 | 6.1 | 0.504 | 25.2 | 14.6 | 10 | 26 | 13.9 | 10.8 |

| CH270GT | 33 | 75 | 156 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CH300GT | 29 | 68 | 141 | 7.27 | 0.652 | 30 | 17.4 | 10.9 | 30.8 | 16.7 | 11.8 |

| CH330GT | 26 | 61 | 127 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CH343GT | 16 | 38 | 79 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CH358GT | 24 | 56 | 117 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CH378GT | 30 | 70 | 145 | 9.4 | 0.867 | 37.8 | 23.2 | 12.5 | 38.7 | 22.3 | 13.4 |

| CH400GT | 35 | 81 | 169 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| CH434GT | 40 | 92 | 191 | 10.74 | 1.308 | 43.4 | 26.4 | 16.2 | 44.3 | 25.5 | 17.1 |

| CH467GT | 59 | 135 | 281 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| CH468GT | 37 | 86 | 179 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| CH488GT | 44 | 101 | 210 | 11.74 | 1.569 | 48.8 | 27.9 | 15.8 | 49.7 | 27 | 16.7 |

| CH508GT | 32 | 73 | 152 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 |

| CH540GT | 44 | 102 | 213 | 12.63 | 1.71 | 54 | 29 | 14.4 | 54.9 | 28.1 | 15.3 |

| CH571GT | 60 | 138 | 288 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 |

| CH572GT | 33 | 75 | 156 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 |

| CH596GT | 54 | 125 | 260 | 14.33 | 2.371 | 59.6 | 34 | 19.5 | 60.6 | 33 | 20.5 |

| CH610GT | 83 | 192 | 400 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 |

| CH640GT | 49 | 113 | 234 | 16.04 | 2.394 | 64 | 40 | 21 | 65.1 | 39 | 22.1 |

| CH680GT | 62 | 143 | 299 | 15.81 | 3.008 | 68 | 36 | 20 | 69.1 | 35 | 21.1 |

| CH740GT | 89 | 206 | 429 | 18.39 | 4.788 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 |

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

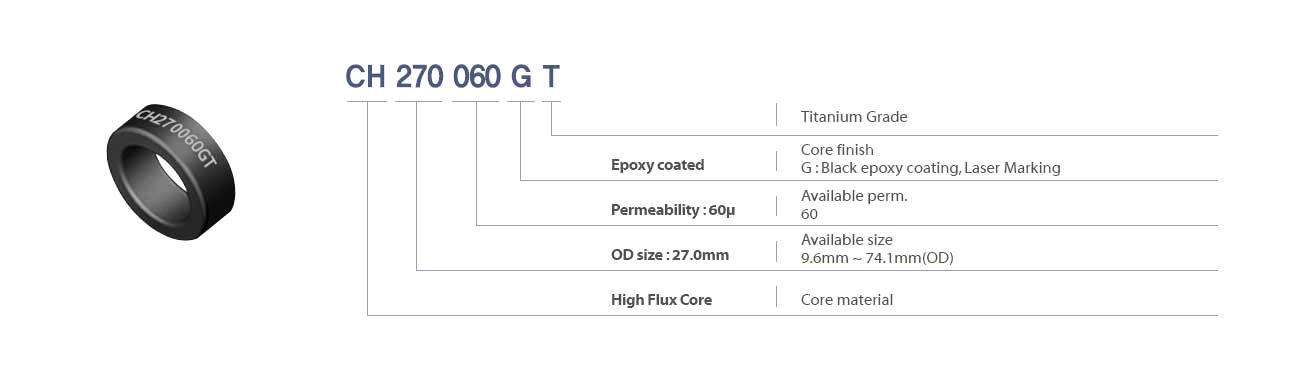

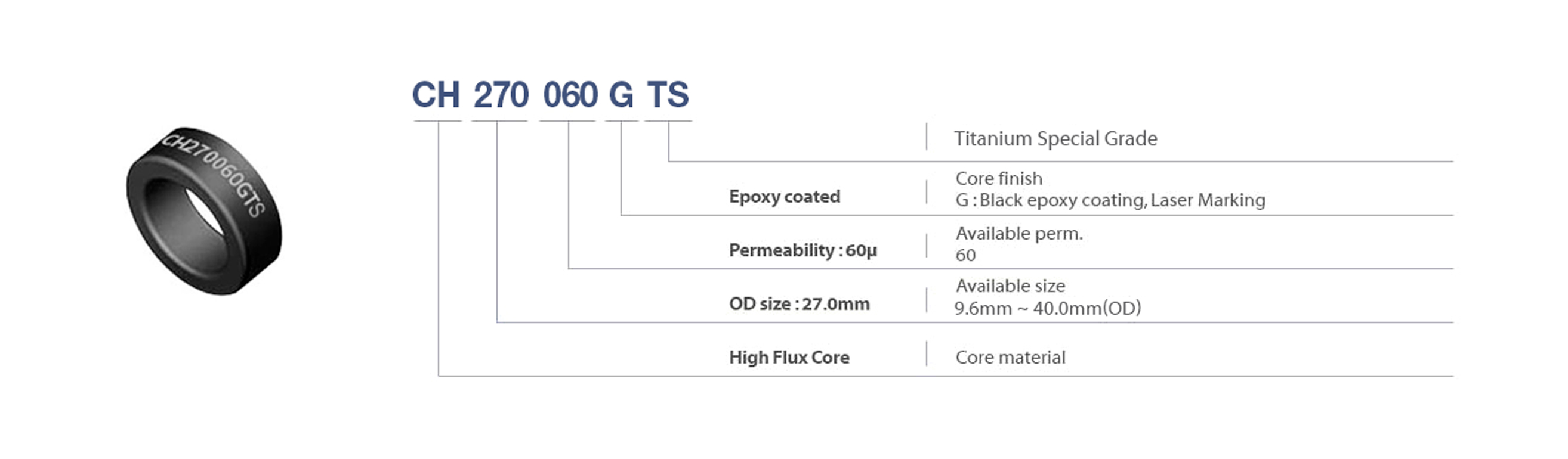

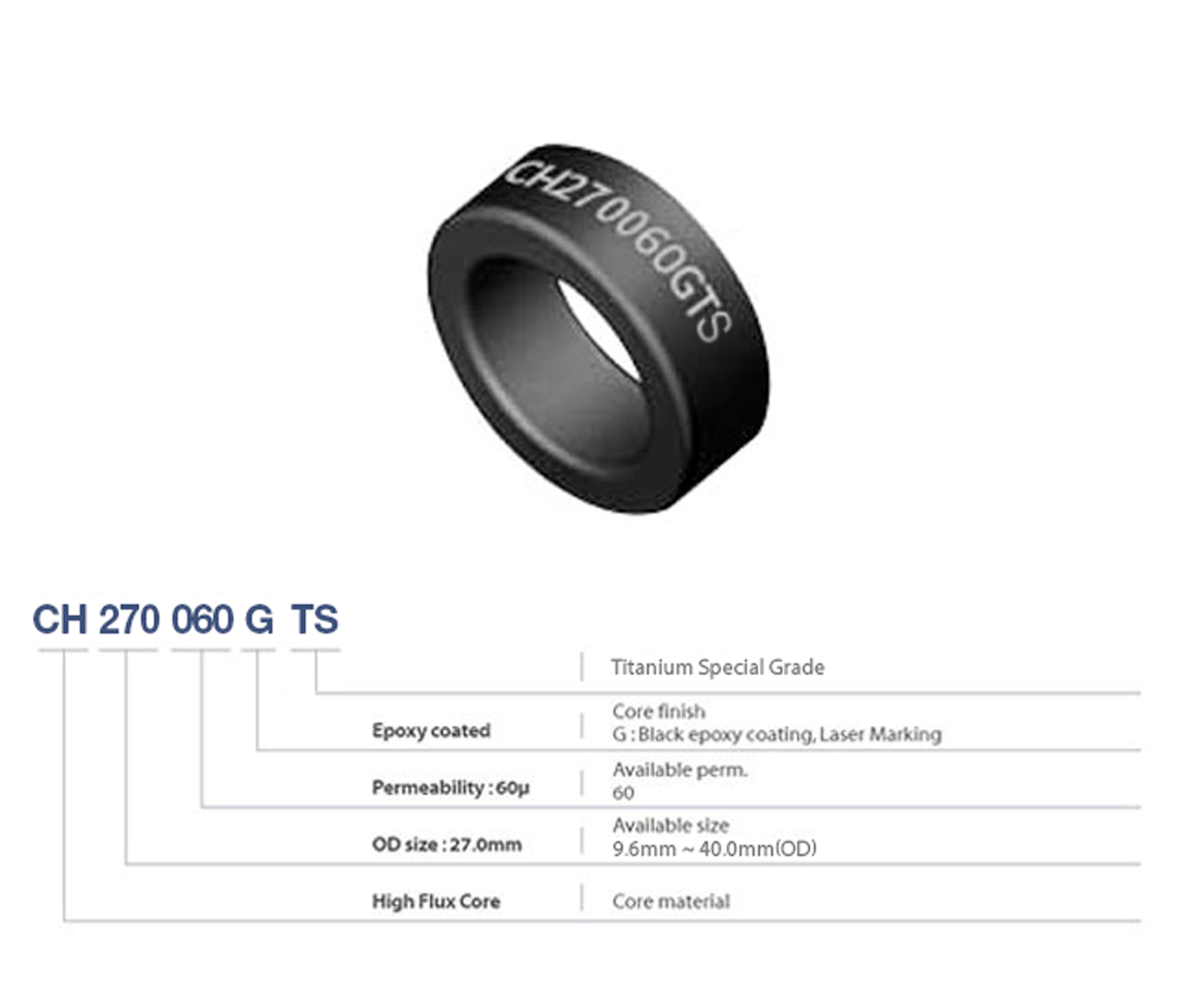

钛金S系列

钛金S系列的高磁通铁镍磁芯(High Flux GTS)是钛金系列的高磁通铁镍磁芯 (High Flux GT) 的升级版材料,专门为诸如人工智能计算和数据中心等需要高效率的供电系统而设计。 与之前的钛金系列相比,钛金S系列具有更优的叠加特性,并且损耗降低了 25%。

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||

| 060u | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CH097GTS | 32 | 2.18 | 0.095 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| CH102GTS | 32 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| CH112GTS | 26 | 2.69 | 0.091 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| CH127GTS | 27 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| CH147GTS | 32 | 3.63 | 0.154 | 14.7 | 8.9 | 5.6 | 15.5 | 8.2 | 6.4 |

| CH166GTS | 35 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| CH172GTS | 43 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| CH203GTS | 32 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| CH229GTS | 43 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| CH234GTS | 51 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CH252GTS | 62 | 6.1 | 0.504 | 25.2 | 14.6 | 10 | 26 | 13.9 | 10.8 |

| CH270GTS | 75 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CH300GTS | 68 | 7.27 | 0.652 | 30 | 17.4 | 10.9 | 30.8 | 16.7 | 11.8 |

| CH330GTS | 61 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CH343GTS | 38 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CH358GTS | 56 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CH378GTS | 70 | 9.4 | 0.867 | 37.8 | 23.2 | 12.5 | 38.7 | 22.3 | 13.4 |

| CH400GTS | 81 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

环形磁粉芯

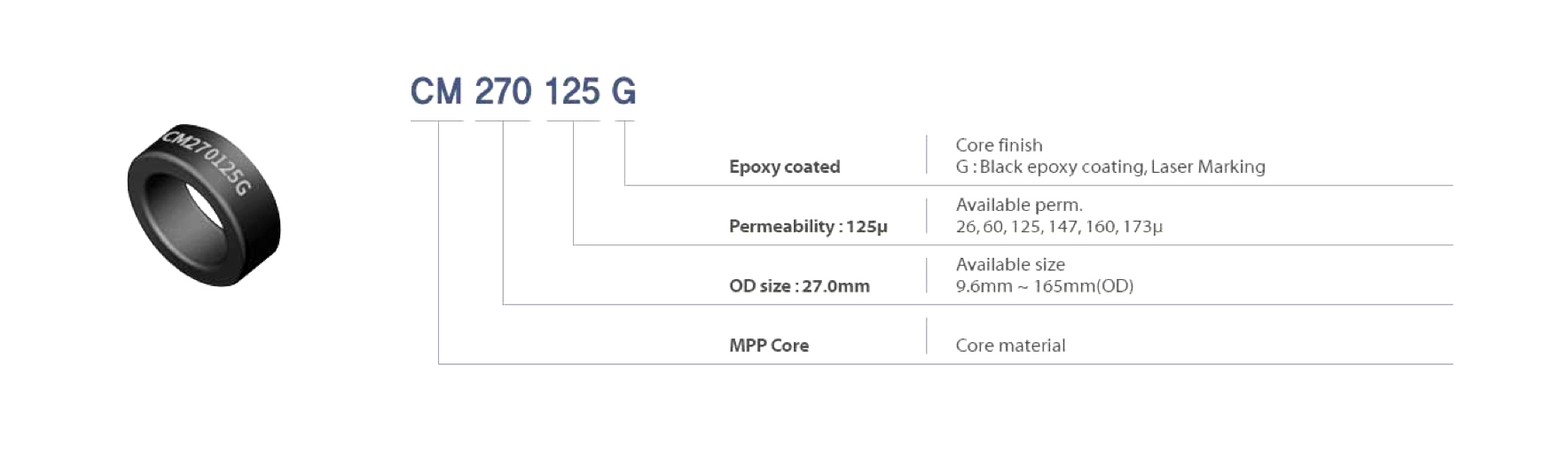

铁镍钼(MPP)

铁镍钼(MPP)磁芯是可实现最低损耗和最高磁导率的材料。铁镍钼磁芯在高直流磁化或高直流叠加条件下,可保证良好的温度和电感特性的稳定性。因此,铁镍钼磁芯主要应用于航空航天,国防,医疗设备的SMPS用电感(HIGH Q filter , Loading Coils,EMI/RFI filter)等要求可靠性和稳定性的领域。

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | |||||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | |||||||||

| 26 | 60 | 125 | 147 | 160 | 173 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CM096 | 11 | 25 | 53 | 63 | 68 | 74 | 2.18 | 0.0752 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 |

| CM097 | 14 | 32 | 66 | 78 | 84 | 92 | 2.18 | 0.0945 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| CM102 | 14 | 32 | 66 | 78 | 84 | 92 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| CM112 | 11 | 26 | 53 | 63 | 68 | 74 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| CM127 | 12 | 27 | 56 | 67 | 72 | 79 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| CM166 | 15 | 35 | 72 | 88 | 92 | 104 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| CM172 | 19 | 43 | 89 | 105 | 114 | 123 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| CM203 | 14 | 32 | 68 | 81 | 87 | 96 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| CM229 | 19 | 43 | 90 | 106 | 115 | 124 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| CM234 | 22 | 51 | 105 | 124 | 135 | 146 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CM270 | 32 | 75 | 157 | 185 | 201 | 217 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CM330 | 28 | 61 | 127 | 150 | 163 | 176 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CM343 | 16 | 38 | 79 | 93 | 101 | 109 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CM358 | 24 | 56 | 117 | 138 | 150 | 162 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CM400 | 35 | 81 | 168 | 198 | 215 | 233 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| CM467 | 59 | 135 | 281 | 33 | 360 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 | |

| CM468 | 37 | 86 | 178 | 210 | 228 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 | |

| CM508 | 32 | 73 | 152 | 179 | 195 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 | |

| CM571 | 60 | 138 | 287 | 306 | 333 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 | |

| CM572 | 33 | 75 | 156 | 185 | 200 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 | |

| CM610 | 83 | 192 | 400 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 | |||

| CM740 | 89 | 206 | 429 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 | |||

| CM777 | 30 | 68 | 142 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 | |||

| CM778 | 37 | 85 | 178 | 20 | 2.27 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 | |||

| CM1013 | 40 | 92 | 192 | 24.27 | 2.97 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 | |||

| CM1016 | 47 | 112 | 228 | 24.27 | 3.52 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 | |||

| CM1027 | 80 | 184 | 384 | 24.27 | 5.94 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 | |||

| CM1033 | 94 | 224 | 456 | 24.27 | 7.04 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 | |||

| CM1320 | 54 | 124 | 259 | 32.42 | 5.35 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 | |||

| CM1325 | 68 | 156 | 325 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 | |||

| CM1333 | 88 | 202 | 422 | 32.42 | 8.72 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 | |||

| CM1340 | 108 | 248 | 518 | 32.42 | 10.69 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 | |||

| CM1625 | 80 | 184 | 384 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 | |||

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

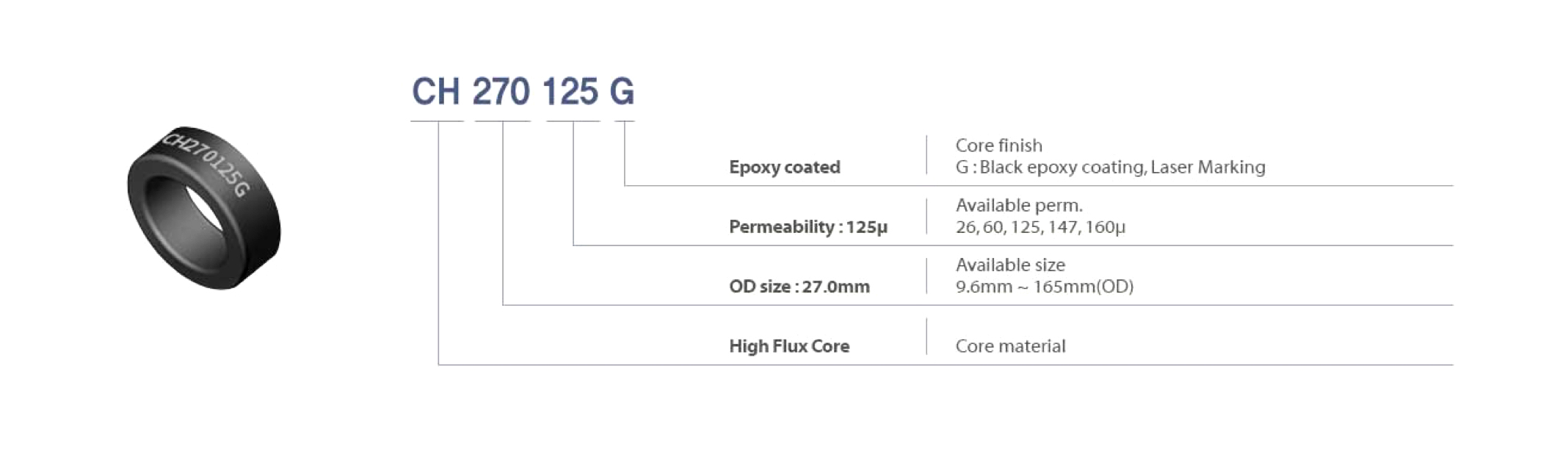

铁镍 (High Flux)

高磁通铁镍(High Flux)磁芯的磁通密度为15,000Gauss,与类似大小的气隙铁氧体或铁粉磁芯相比, 磁导率及储能能力均相对较高。 高磁通铁镍磁芯的直流叠加特性和低损耗特性在减少电感器体积和圈数的同时,可提供最优的磁性能。 因此,在功效因数校正器(PFC),开关调节器(Switching regulator inductor),噪声滤波器(in-line noise filter),脉冲变压器 (pulse transformer),反激变压器(flyback transformer)等领域,CSC的高磁通铁镍磁芯是您最佳的选择。

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||||

| 26 | 60 | 125 | 147 | 160 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CH096 | 11 | 25 | 53 | 63 | 68 | 2.18 | 0.0752 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 |

| CH097 | 14 | 32 | 66 | 78 | 84 | 2.18 | 0.0945 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| CH102 | 14 | 32 | 66 | 78 | 84 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| CH112 | 11 | 26 | 53 | 63 | 68 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| CH127 | 12 | 27 | 56 | 67 | 72 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| CH166 | 15 | 35 | 72 | 88 | 92 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| CH172 | 19 | 43 | 89 | 105 | 114 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| CH203 | 14 | 32 | 68 | 81 | 87 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| CH229 | 19 | 43 | 90 | 106 | 115 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| CH234 | 22 | 51 | 105 | 124 | 135 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CH270 | 32 | 75 | 157 | 185 | 201 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CH330 | 28 | 61 | 127 | 150 | 163 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CH343 | 16 | 38 | 79 | 93 | 101 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CH358 | 24 | 56 | 117 | 138 | 150 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CH400 | 35 | 81 | 168 | 198 | 215 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| CH467 | 59 | 135 | 281 | 33 | 360 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| CH468 | 37 | 86 | 178 | 210 | 228 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| CH508 | 32 | 73 | 152 | 179 | 195 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 |

| CH571 | 60 | 138 | 287 | 306 | 333 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 |

| CH572 | 33 | 75 | 156 | 185 | 200 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 |

| CH610 | 83 | 192 | 400 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 | ||

| CH740 | 89 | 206 | 429 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 | ||

| CH777 | 30 | 68 | 142 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 | ||

| CH778 | 37 | 85 | 178 | 20 | 2.27 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 | ||

| CH1013 | 40 | 92 | 192 | 24.27 | 2.97 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 | ||

| CH1016 | 47 | 112 | 228 | 24.27 | 3.52 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 | ||

| CH1027 | 80 | 184 | 384 | 24.27 | 5.94 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 | ||

| CH1033 | 94 | 224 | 456 | 24.27 | 7.04 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 | ||

| CH1320 | 54 | 124 | 259 | 32.42 | 5.35 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 | ||

| CH1325 | 68 | 156 | 325 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 | ||

| CH1333 | 88 | 202 | 422 | 32.42 | 8.72 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 | ||

| CH1340 | 108 | 248 | 518 | 32.42 | 10.69 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 | ||

| CH1625 | 80 | 184 | 384 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 | ||

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

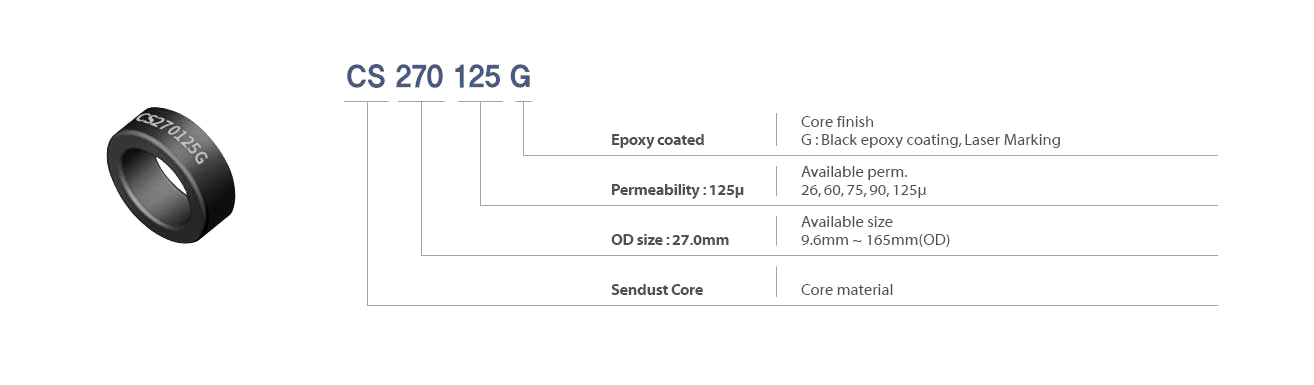

铁硅铝(Sendust)

铁硅铝(Sendust)磁芯的近零磁致伸缩特性,可有效消除电感器中的可听噪音。 铁硅铝(Sendust)磁芯的损耗远低于铁粉磁芯的损耗。尤其是铁硅铝(Sendust) E型磁芯比气隙铁氧体E型磁芯储能更高。使用铁硅铝(Sendust)E 型磁芯可以最大限度的减少气隙损耗和涡流损耗。可以说,将铁硅铝(Sendust)磁芯应用于PFC电路上是最明智的选择。其他主要应用领域还有开关调节电感(Switching regulator inductor),噪声滤波器(in-line noise filter),脉冲变压器(pulse transformer),反激变压器(flyback transformer)等。

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||||

| 26 | 60 | 75 | 90 | 125 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CS096 | 11 | 25 | 32 | 38 | 53 | 2.18 | 0.0752 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 |

| CS097 | 14 | 32 | 40 | 48 | 66 | 2.18 | 0.0945 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| CS102 | 14 | 32 | 40 | 48 | 66 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| CS112 | 11 | 26 | 32 | 38 | 53 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| CS127 | 12 | 27 | 34 | 40 | 56 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| CS166 | 15 | 35 | 43 | 52 | 72 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| CS172 | 19 | 43 | 53 | 64 | 89 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| CS203 | 14 | 32 | 41 | 49 | 68 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| CS229 | 19 | 43 | 54 | 65 | 90 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| CS234 | 22 | 51 | 63 | 76 | 105 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CS270 | 32 | 75 | 94 | 113 | 157 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CS330 | 28 | 61 | 76 | 91 | 127 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CS343 | 16 | 38 | 47 | 57 | 79 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CS358 | 24 | 56 | 70 | 84 | 117 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CS400 | 35 | 81 | 101 | 121 | 168 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| CS467 | 59 | 135 | 169 | 202 | 281 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| CS468 | 37 | 86 | 107 | 128 | 178 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| CS508 | 32 | 73 | 91 | 109 | 152 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 |

| CS571 | 60 | 138 | 172 | 206 | 287 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 |

| CS572 | 33 | 75 | 94 | 112 | 156 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 |

| CS610 | 83 | 192 | 240 | 288 | 400 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 |

| CS740 | 89 | 206 | 257 | 309 | 429 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 |

| CS777 | 30 | 68 | 85 | 102 | 124 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 |

| CS778 | 37 | 85 | 107 | 128 | 178 | 20 | 2.27 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 |

| CS1013 | 40 | 92 | 115 | 138 | 445 | 24.27 | 2.97 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 |

| CS1016 | 47 | 112 | 137 | 134 | 540 | 24.27 | 3.52 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 |

| CS1027 | 80 | 184 | 231 | 277 | 890 | 24.27 | 5.94 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 |

| CS1033 | 94 | 224 | 273 | 328 | 1080 | 24.27 | 7.04 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 |

| CS1320 | 54 | 124 | 155 | 186 | 1064 | 32.42 | 5.35 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 |

| CS1325 | 68 | 156 | 195 | 234 | 1332 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 |

| CS1333 | 88 | 202 | 253 | 304 | 1730 | 32.42 | 8.72 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 |

| CS1340 | 108 | 248 | 311 | 373 | 2128 | 32.42 | 10.69 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 |

| CS1625 | 80 | 184 | 230 | 277 | 2280 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 |

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

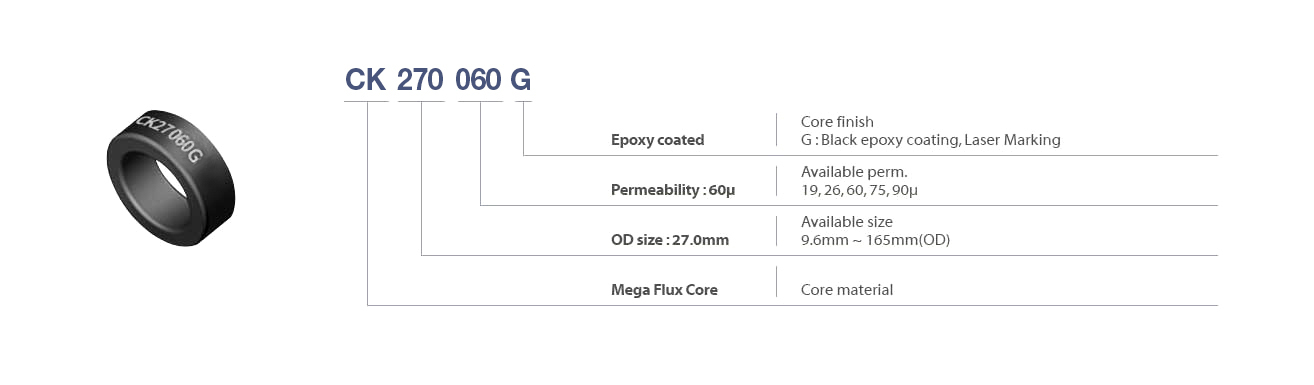

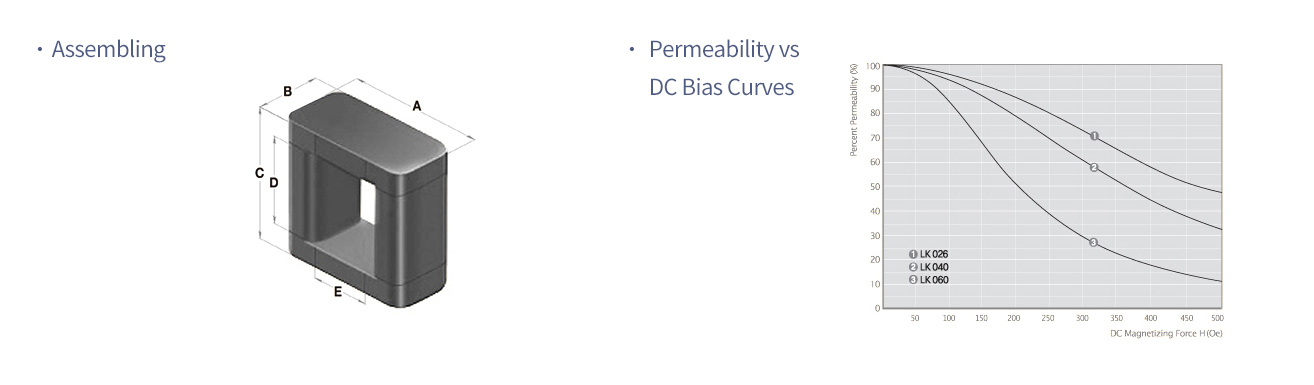

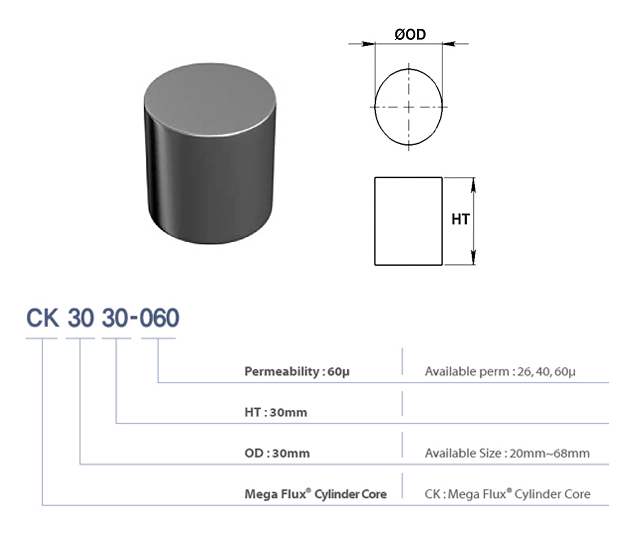

铁硅 (Mega Flux)

CSC是全球首家用铁和硅制作磁粉芯的公司。创造性的铁硅(Mega Flux)磁芯的磁通密度为16,000Gauss,相比高磁通铁镍(High Flux,磁通密度为15,000Gauss)和铁硅铝磁芯(Sendust,磁通密度为10,000Gauss)磁通密度更高。其优秀的直流叠加特性可为高功率系统的降压/升压电感器、平滑扼流器(Smoothing Choke)和电动汽车的电感器等各种高效应用领域上了最佳方案。铁硅(Mega Flux)磁芯损耗明显低于铁粉芯和硅钢片(Fe-Si strip cores),且 Mega Flux磁芯具有良好的热性能,无需担心因热老化问题。

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||||

| 19 | 26 | 60 | 75 | 90 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CK096 | 11 | 25 | 31 | 38 | 2.18 | 0.075 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 | |

| CK097 | 14 | 32 | 40 | 48 | 2.18 | 0.095 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 | |

| CK112 | 11 | 26 | 32 | 38 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 | |

| CK127 | 12 | 27 | 34 | 40 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 | |

| CK166 | 15 | 35 | 43 | 52 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 | |

| CK172 | 19 | 43 | 53 | 64 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 | |

| CK203 | 14 | 32 | 41 | 49 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 | |

| CK229 | 19 | 43 | 54 | 65 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 | |

| CK234 | 16 | 22 | 51 | 63 | 76 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CK270 | 24 | 32 | 75 | 94 | 113 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CK330 | 19 | 28 | 61 | 76 | 91 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CK343 | 12 | 16 | 38 | 47 | 57 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CK358 | 18 | 24 | 56 | 70 | 84 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CK400 | 26 | 35 | 81 | 101 | 121 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| CK467 | 43 | 59 | 135 | 169 | 202> | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| CK468 | 27 | 37 | 86 | 107 | 128 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| CK508 | 23 | 32 | 73 | 91 | 109 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 |

| CK571 | 44 | 60 | 138 | 172 | 206 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 |

| CK572 | 24 | 33 | 75 | 94 | 112 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 |

| CK610 | 61 | 83 | 192 | 240 | 288 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 |

| CK740 | 65 | 89 | 206 | 257 | 309 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 |

| CK777 | 22 | 30 | 68 | 85 | 102 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 |

| CK778 | 27 | 37 | 85 | 107 | 128 | 20 | 2.77 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 |

| CK1013 | 29 | 40 | 92 | 192 | 24.27 | 2.97 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 | |

| CK1016 | 35 | 47 | 112 | 228 | 24.27 | 3.52 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 | |

| CK1027 | 58 | 80 | 184 | 384 | 24.27 | 5.94 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 | |

| CK1033 | 70 | 94 | 224 | 456 | 24.27 | 7.04 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 | |

| CK1320 | 39 | 54 | 124 | 259 | 32.42 | 5.35 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 | |

| CK1325 | 49 | 68 | 156 | 325 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 | |

| CK1333 | 64 | 88 | 202 | 422 | 32.42 | 8.72 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 | |

| CK1340 | 79 | 108 | 248 | 518 | 32.42 | 10.69 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 | |

| CK1625 | 58 | 80 | 184 | 384 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 | |

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

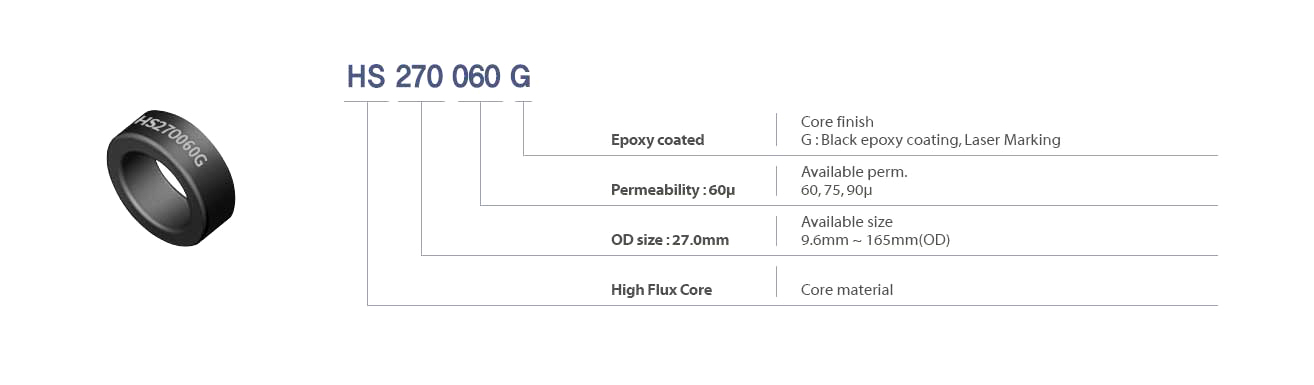

HS Cores

HS磁芯比铁硅铝(Sendust)磁芯具有更好的直流叠加(DCB)特性和更低的损耗。HS磁芯在大功率台式电脑、服务器电脑、汽车和光伏等各种高效应用领域上提供最经济的方案。 另外, 不像磁粉芯存在热老化问题,HS磁芯具有良好的热性能,可成为替代非晶磁芯的良好方案。

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||

| 60 | 75 | 90 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| HS096 | 25 | 32 | 38 | 2.18 | 0.0752 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 |

| HS097 | 32 | 40 | 48 | 2.18 | 0.0945 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| HS102 | 32 | 40 | 48 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| HS112 | 26 | 32 | 38 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| HS127 | 27 | 34 | 40 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| HS166 | 35 | 43 | 52 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| HS172 | 43 | 53 | 64 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| HS203 | 32 | 41 | 49 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| HS229 | 43 | 54 | 65 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| HS234 | 51 | 63 | 76 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| HS270 | 75 | 94 | 113 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| HS330 | 61 | 76 | 91 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| HS343 | 38 | 47 | 57 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| HS358 | 56 | 70 | 84 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| HS400 | 81 | 101 | 121 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| HS467 | 135 | 169 | 202 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| HS468 | 86 | 107 | 128 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| HS508 | 73 | 91 | 109 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 |

| HS571 | 138 | 172 | 206 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 |

| HS572 | 75 | 94 | 112 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 |

| HS610 | 192 | 240 | 288 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 |

| HS740 | 206 | 257 | 309 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 |

| HS777 | 68 | 85 | 102 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 |

| HS778 | 85 | 107 | 128 | 20 | 2.27 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 |

| HS1013 | 92 | 24.27 | 2.972 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 | ||

| HS1016 | 112 | 24.27 | 3.522 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 | ||

| HS1027 | 184 | 24.27 | 5.944 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 | ||

| HS1033 | 224 | 24.27 | 7.044 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 | ||

| HS1320 | 124 | 32.42 | 5.347 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 | ||

| HS1325 | 156 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 | ||

| HS1333 | 202 | 32.42 | 8.717 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 | ||

| HS1340 | 248 | 32.42 | 10.694 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 | ||

| HS1625 | 184 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 | ||

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

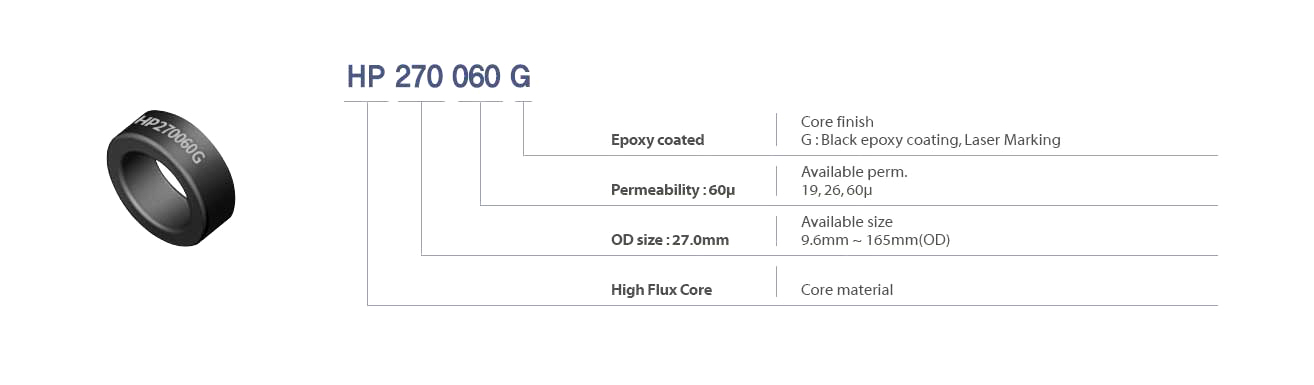

HP Cores

几乎为零磁致伸缩的HP磁芯是消除电感器可听噪声的理想选择。尤其是19u和26u的磁芯损耗远低于其他材料,甚至低于MPP。HP 19u 和 26u 为 UPS 和 ESS 等需要高效率的应用提供的解决方案。HP 60u是在高频率中可以最大化降低设备温度的最低损失的材料,它适用于中小型电源服务器和电动汽车充电器应用的 PFC 和输出电感,可以很好地替代非晶磁芯。

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||

| 19 | 26 | 60 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| HP096 | 11 | 25 | 2.18 | 0.0752 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 | |

| HP097 | 14 | 32 | 2.18 | 0.0945 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 | |

| HP102 | 14 | 32 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 | |

| HP112 | 11 | 26 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 | |

| HP127 | 12 | 27 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 | |

| HP166 | 25 | 35 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 | |

| HP172 | 19 | 43 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 | |

| HP203 | 14 | 32 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 | |

| HP229 | 19 | 43 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 | |

| HP234 | 22 | 51 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 | |

| HP270 | 24 | 33 | 75 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| HP330 | 19 | 26 | 61 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| HP343 | 12 | 16 | 38 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| HP358 | 18 | 24 | 56 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| HP400 | 26 | 35 | 81 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| HP467 | 43 | 59 | 135 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| HP468 | 27 | 37 | 86 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| HP508 | 23 | 32 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 | |

| HP571 | 44 | 60 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 | |

| HP572 | 24 | 33 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 | |

| HP610 | 61 | 83 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 | |

| HP740 | 61 | 89 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 | |

| HP777 | 22 | 29 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 | |

| HP778 | 27 | 37 | 20 | 2.27 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 | |

| HP1013 | 29 | 40 | 24.27 | 2.972 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 | |

| HP1016 | 35 | 49 | 24.27 | 3.522 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 | |

| HP1027 | 58 | 80 | 24.27 | 5.944 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 | |

| HP1033 | 71 | 97 | 24.27 | 7.044 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 | |

| HP1320 | 39 | 54 | 32.42 | 5.347 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 | |

| HP1325 | 49 | 68 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 | |

| HP1333 | 64 | 88 | 32.42 | 8.717 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 | |

| HP1340 | 79 | 107 | 32.42 | 10.694 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 | |

| HP1625 | 58 | 80 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 | |

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

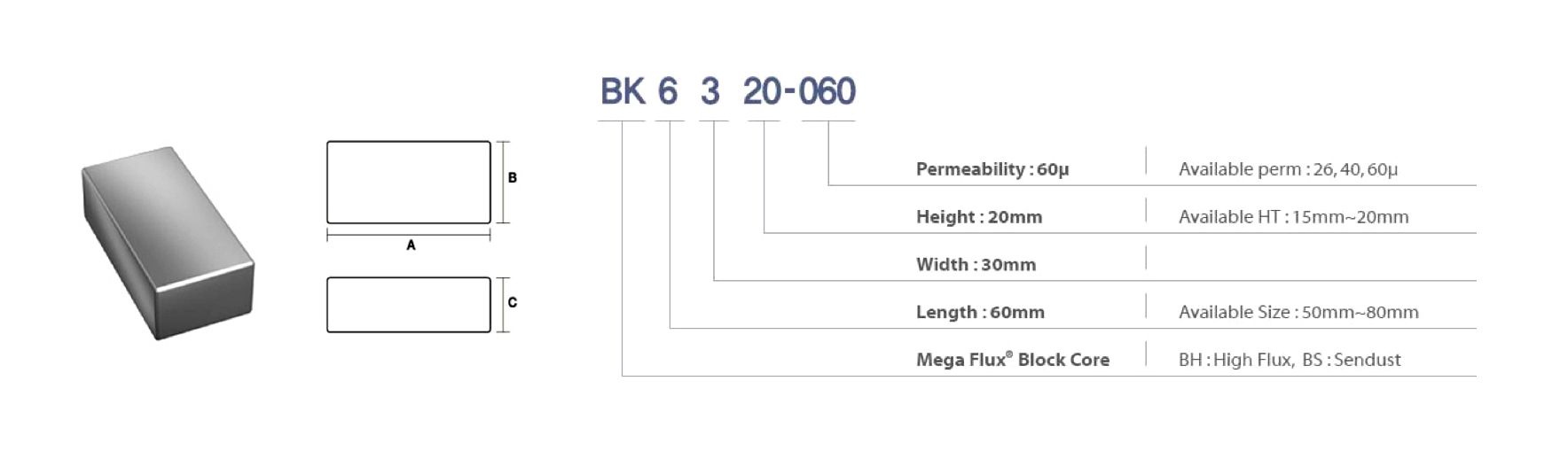

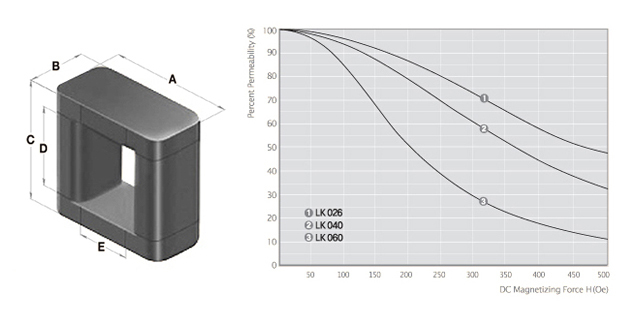

特殊形状

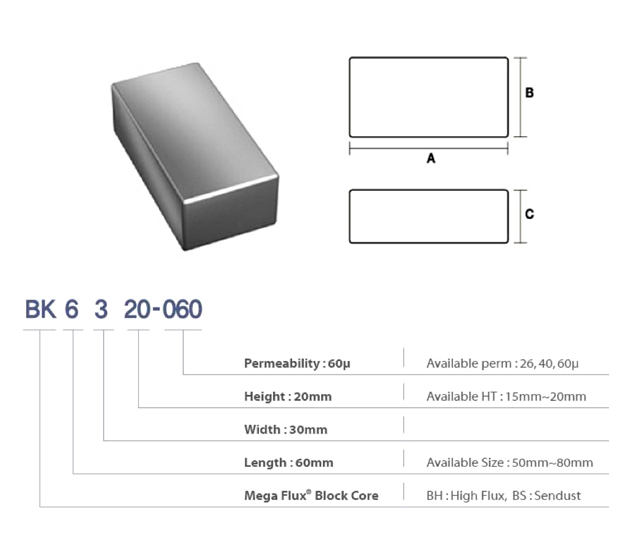

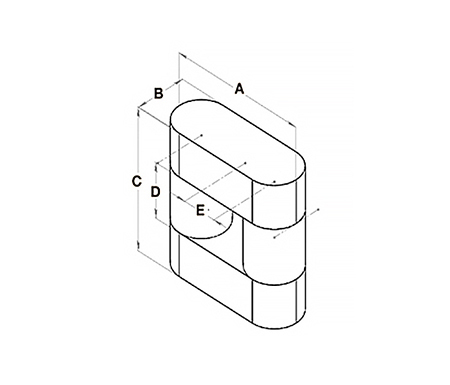

条状磁粉芯

可根据用户的需求,实现多样化的电感结构,具有高难度绕线的可行性,可轻松实现组装型电感的制造。同时,还可以保持较大的储能量、高温下的稳定性、较低的磁芯损耗、高工作频率等磁粉芯的基本优点

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | 4PCS AL value (nH/N²)±12% | ||||

|---|---|---|---|---|---|---|---|---|

| A Length | B Width | C Height | 026μ | 040μ | 060μ | |||

| BK5315 | 50.5±0.5 | 30.3±0.3 | 15±0.2 | 18.71 | 4.5 | 95 | 121 | 181 |

| BK5320 | 50.5±0.5 | 30.3±0.3 | 20±0.2 | 18.28 | 6 | 130 | 165 | 247 |

| BK6315 | 60.5±0.5 | 30.3±0.3 | 15±0.2 | 22.71 | 4.5 | 79 | 100 | 149 |

| BK6320 | 60.5±0.5 | 30.3±0.3 | 20±0.2 | 22.28 | 6 | 107 | 135 | 203 |

| BK7315 | 70.5±0.5 | 30.3±0.3 | 15±0.2 | 26.71 | 4.5 | 67 | 85 | 127 |

| BK7320 | 70.5±0.5 | 30.3±0.3 | 20±0.2 | 26.28 | 6 | 91 | 115 | 172 |

| BK8315 | 80.5±0.5 | 30.3±0.3 | 15±0.2 | 30.71 | 4.5 | 58 | 74 | 110 |

| BK8320 | 80.5±0.5 | 30.3±0.3 | 20±0.2 | 30.28 | 6 | 78 | 100 | 149 |

| BK9315 | 90.5±0.5 | 30.3±0.3 | 15±0.2 | 34.71 | 4.5 | 51 | 65 | 98 |

| BK9320 | 90.5±0.5 | 30.3±0.3 | 20±0.2 | 34.28 | 6 | 68 | 88 | 132 |

| BK5020A | 50.5±0.5 | 20.3±0.3 | 20±0.2 | 18.28 | 4 | 87 | 110 | 165 |

| BK6020A | 60.5±0.5 | 20.3±0.3 | 20±0.2 | 22.28 | 4 | 71 | 90 | 135 |

| BK6020B | 60.5±0.5 | 20.3±0.3 | 25±0.2 | 21.85 | 5 | 91 | 115 | 173 |

| BK7020A | 70.5±0.5 | 20.3±0.3 | 20±0.2 | 26.28 | 4 | 60 | 77 | 115 |

| BK7020B | 70.5±0.5 | 20.3±0.3 | 25±0.2 | 25.85 | 5 | 77 | 97 | 146 |

| BK8020A | 80.5±0.5 | 20.3±0.3 | 20±0.2 | 30.28 | 4 | 52 | 66 | 100 |

| BK8020B | 80.5±0.5 | 20.3±0.3 | 25±0.2 | 29.85 | 5 | 66 | 84 | 126 |

※ BS(Sendust Block Core), BH(HighFlux Core) and customized designs are also available.

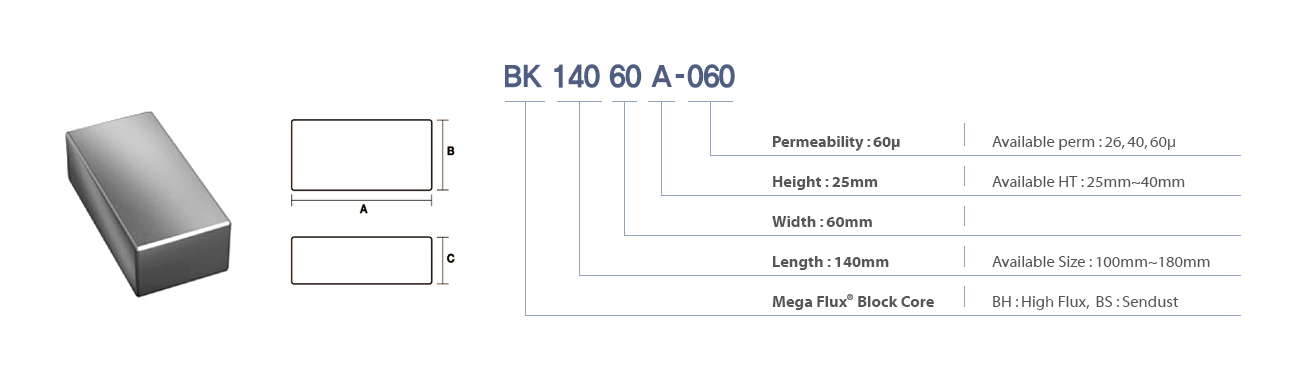

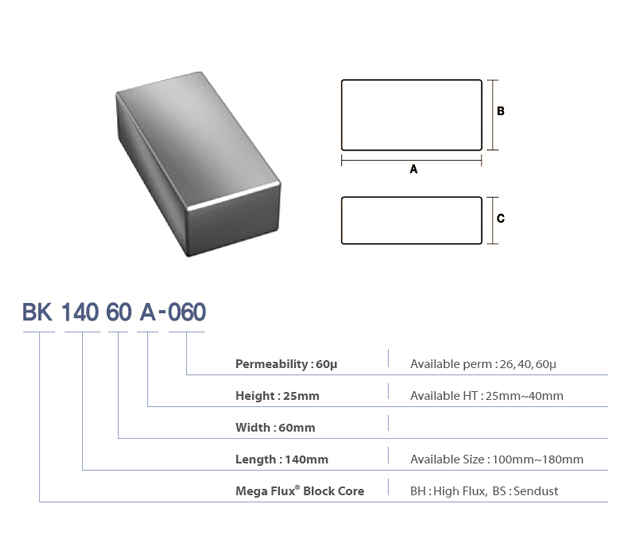

大型条状磁粉芯

可实现更大功率的电感组装,便于用户实现多样化的电感组装结构,具有高难度绕线的可行性,可轻松实现组装型电感。同时,还可以保持较大的储能量、高温下的稳定性、较低的磁芯损耗、高工作频率等磁粉芯的基本优点。

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | 4PCS AL value (nH/N²)±12% | ||||

|---|---|---|---|---|---|---|---|---|

| A Length | B Width | C Height | 026μ | 040μ | 060μ | |||

| BK10060A | 100.6±1.0 | 60.5±0.6 | 25±0.6 | 37.85 | 15 | 157 | 199 | 299 |

| BK10060B | 100.6±1.0 | 60.5±0.6 | 30±0.6 | 37.42 | 18 | 191 | 242 | 362 |

| BK10060C | 100.6±1.0 | 60.5±0.6 | 35±0.8 | 37 | 21 | 225 | 285 | 428 |

| BK10060D | 100.6±1.0 | 60.5±0.6 | 40±0.8 | 36.57 | 24 | 260 | 330 | 495 |

| BK11060A | 110.6±1.0 | 60.5±0.6 | 25±0.6 | 41.85 | 15 | 142 | 180 | 270 |

| BK11060B | 110.6±1.0 | 60.5±0.6 | 30±0.6 | 41.42 | 18 | 172 | 218 | 327 |

| BK11060C | 110.6±1.0 | 60.5±0.6 | 35±0.8 | 41 | 21 | 203 | 257 | 386 |

| BK11060D | 110.6±1.0 | 60.5±0.6 | 40±0.8 | 40.57 | 24 | 235 | 297 | 446 |

| BK12060A | 120.6±1.0 | 60.5±0.6 | 25±0.6 | 45.85 | 15 | 130 | 164 | 246 |

| BK12060B | 120.6±1.0 | 60.5±0.6 | 30±0.6 | 45.42 | 18 | 157 | 199 | 299 |

| BK12060C | 120.6±1.0 | 60.5±0.6 | 35±0.8 | 45 | 21 | 185 | 234 | 352 |

| BK12060D | 120.6±1.0 | 60.5±0.6 | 40±0.8 | 44.57 | 24 | 214 | 270 | 406 |

| BK14060A | 140.6±1.0 | 60.5±0.6 | 25±0.6 | 53.85 | 15 | 111 | 140 | 210 |

| BK14060B | 140.6±1.0 | 60.5±0.6 | 30±0.6 | 53.42 | 18 | 134 | 169 | 254 |

| BK14060C | 140.6±1.0 | 60.5±0.6 | 35±0.8 | 53 | 21 | 157 | 199 | 299 |

| BK14060D | 140.6±1.0 | 60.5±0.6 | 40±0.8 | 52.57 | 24 | 181 | 229 | 344 |

| BK16060A | 160.6±1.0 | 60.5±0.6 | 25±0.6 | 61.85 | 15 | 96 | 122 | 183 |

| BK16060B | 160.6±1.0 | 60.5±0.6 | 30±0.6 | 61.42 | 18 | 116 | 147 | 221 |

| BK16060C | 160.6±1.0 | 60.5±0.6 | 35±0.8 | 61 | 21 | 137 | 173 | 259 |

| BK16060D | 160.6±1.0 | 60.5±0.6 | 40±0.8 | 60.57 | 24 | 157 | 199 | 299 |

| BK18060A | 180.6±1.0 | 60.5±0.6 | 25±0.6 | 69.85 | 15 | 85 | 108 | 162 |

| BK18060B | 180.6±1.0 | 60.5±0.6 | 30±0.6 | 69.42 | 18 | 103 | 130 | 195 |

| BK18060C | 180.6±1.0 | 60.5±0.6 | 35±0.8 | 69 | 21 | 121 | 153 | 229 |

| BK18060D | 180.6±1.0 | 60.5±0.6 | 40±0.8 | 68.57 | 24 | 139 | 176 | 264 |

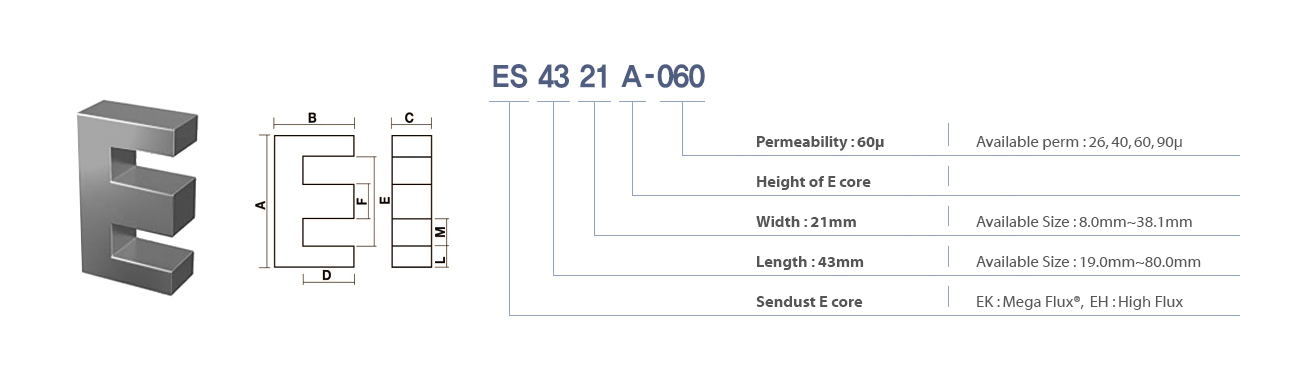

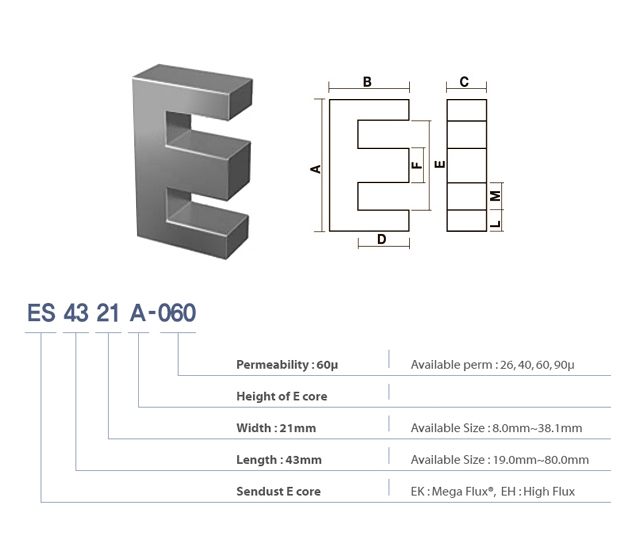

E型磁粉芯

易于确保高感量,与同等特性的其他形状相比,易于实现高度较低的电感。同时,还可以保持较大的储能量、高温下的稳定性、较低的磁芯损耗、高工作频率等磁粉芯的基本优点。

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D(min) | E(min) | F | L(nom) | M(min) | 026μ | 040μ | 060μ | 090μ | |||

| ES 1908A | 19.3±0.3 | 8.1±0.2 | 4.8±0.2 | 5.5 | 13.9 | 4.8±0.2 | 2.3 | 4.7 | 4.01 | 0.228 | 26 | 35 | 48 | 69 |

| ES 2510A | 25.1±0.3 | 9.6±0.2 | 6.5±0.2 | 6.2 | 18.8 | 6.1±0.2 | 3 | 6.3 | 4.85 | 0.385 | 39 | 52 | 70 | 100 |

| ES 3015A | 30.1±0.3 | 15.0±0.2 | 7.1±0.2 | 9.7 | 19.5 | 7.0±0.2 | 5.1 | 6.4 | 6.56 | 0.601 | 33 | 46 | 71 | 92 |

| ES 3515A | 34.5±0.3 | 14.1±0.2 | 9.3±0.2 | 9.6 | 25.3 | 9.3±0.2 | 4.4 | 7.9 | 6.94 | 0.84 | 56 | 75 | 102 | 146 |

| ES 4117A | 40.9±0.6 | 16.5±0.3 | 12.5±0.3 | 10.4 | 28.3 | 12.5±0.3 | 6 | 7.9 | 7.75 | 1.52 | 88 | 119 | 163 | 234 |

| ES 4321A | 42.8±0.7 | 21.1±0.4 | 10.8±0.3 | 15 | 30.4 | 11.7±0.3 | 5.9 | 9.5 | 9.84 | 1.28 | 56 | 76 | 105 | 151 |

| ES 4321B | 42.8±0.7 | 21.1±0.4 | 15.4±0.3 | 15 | 30.4 | 11.7±0.3 | 5.9 | 9.5 | 9.84 | 1.83 | 80 | 108 | 150 | 217 |

| ES 4321C | 42.8±0.7 | 21.1±0.4 | 20.0±0.3 | 15 | 30.4 | 11.7±0.3 | 5.9 | 9.5 | 9.84 | 2.37 | 104 | 140 | 194 | 281 |

| ES 5528A | 54.9±0.8 | 27.6±0.4 | 20.6±0.4 | 18.5 | 37.5 | 16.8±0.4 | 8.4 | 10.3 | 12.3 | 3.5 | 116 | 157 | 219 | |

| ES 5528B | 54.9±0.8 | 27.6±0.4 | 24.6±0.4 | 18.5 | 37.5 | 16.8±0.4 | 8.4 | 10.3 | 12.3 | 4.17 | 138 | 187 | 261 | |

| ES 6533A | 65.1±1.0 | 32.5±0.5 | 27.0±0.4 | 22.2 | 44.2 | 19.7±0.4 | 10 | 12.1 | 14.7 | 5.4 | 162 | 230 | 300 | |

| ES 7228A | 72.4±1.1 | 27.9±0.5 | 19.0±0.4 | 17.8 | 52.6 | 19.1±0.4 | 9.5 | 16.9 | 13.7 | 3.68 | 130 | 173 | 236 | |

| ES 8038A | 80.0±1.2 | 38.1±0.6 | 19.8±0.4 | 28.1 | 59.3 | 19.8±0.4 | 9.9 | 19.8 | 18.5 | 3.89 | 103 | 145 | 190 | |

※ BS(Sendust Block Core), BH(HighFlux Core) and customized designs are also available.

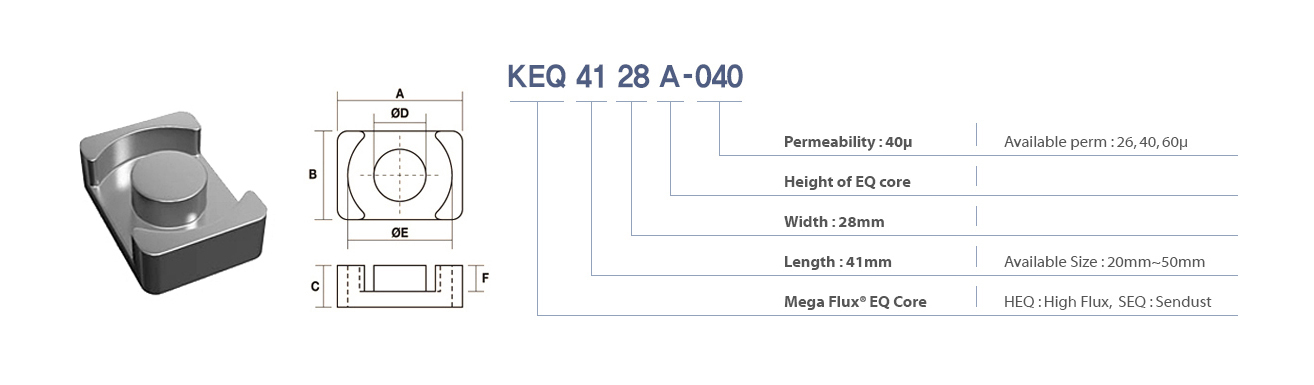

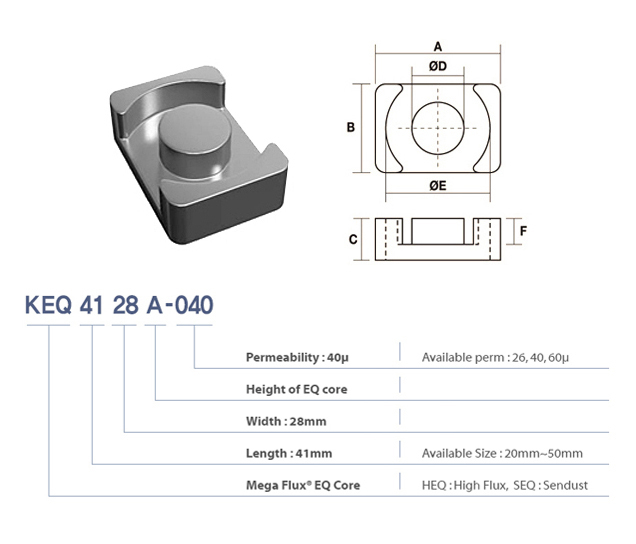

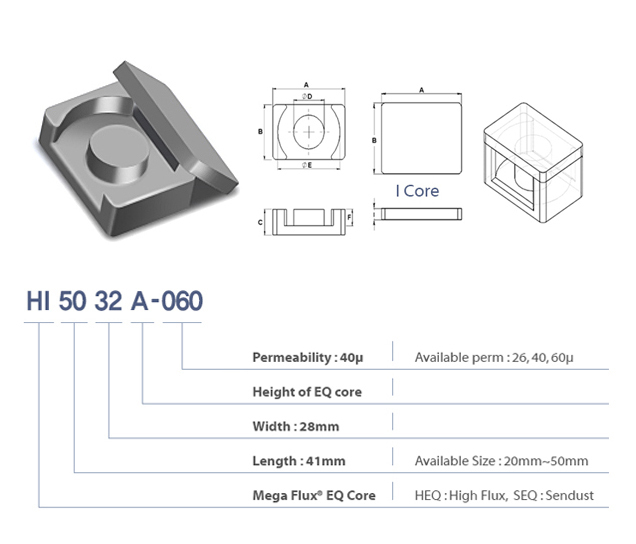

EQ型磁粉芯

适用于大电流功率的电感,并且比其他形状更容易实现低高度的电感。同时,还可以保持较大的储能量、高温下的稳定性、较低的磁芯损耗、高工作频率等磁粉芯的基本优点。并且,无需开气隙,有标准化的磁导率可供选择。

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | 026μ | 040μ | 060μ | |||

| KEQ 2014A | 20.5 ±0.3 | 14.0 ±0.2 | 8.1 ±0.2 | 8.8 ±0.2 | 18.0 ±0.2 | 5.7 ±0.3 | 4.52 | 0.608 | 44 | 68 | 101 |

| KEQ 2014B | 20.5 ±0.3 | 14.0 ±0.2 | 10.1 ±0.2 | 8.8 ±0.2 | 18.0 ±0.2 | 7.7 ±0.3 | 5.32 | 0.608 | 37 | 57 | 86 |

| KEQ 2619A | 26.5 ±0.3 | 19.0 ±0.2 | 10.1 ±0.2 | 12.0 ±0.2 | 22.6 ±0.3 | 6.8 ±0.3 | 5.47 | 1.198 | 72 | 110 | 165 |

| KEQ 2619B | 26.5 ±0.3 | 19.0 ±0.2 | 12.4 ±0.2 | 12.0 ±0.2 | 22.6 ±0.3 | 9.1 ±0.3 | 6.39 | 1.198 | 61 | 94 | 141 |

| KEQ 3222A | 32.0 ±0.4 | 22.0 ±0.3 | 10.3 ±0.2 | 13.5 ±0.2 | 27.6 ±0.3 | 6.6 ±0.3 | 6.03 | 1.523 | 83 | 127 | 190 |

| KEQ 3222B | 32.0 ±0.4 | 22.0 ±0.3 | 15.2 ±0.2 | 13.5 ±0.2 | 27.6 ±0.3 | 11.5 ±0.3 | 7.99 | 1.523 | 62 | 96 | 144 |

| KEQ 3626A | 36.0 ±0.5 | 26.0 ±0.3 | 17.4 ±0.3 | 14.4 ±0.2 | 32.0 ±0.4 | 13.4 ±0.3 | 9.47 | 1.808 | 62 | 96 | 144 |

| KEQ 4128A | 41.5 ±0.5 | 28.0 ±0.4 | 19.9 ±0.3 | 14.9 ±0.2 | 36.5 ±0.4 | 15.4 ±0.3 | 11.52 | 1.997 | 57 | 87 | 131 |

| KEQ 5032A | 50.0 ±0.6 | 32.0 ±0.4 | 25.0 ±0.4 | 20.0 ±0.3 | 44.0 ±0.5 | 19.5 ±0.4 | 13.34 | 3.141 | 77 | 118 | 178 |

※ KEQ (MegaFlux Cores), HEQ (High Flux Cores), SEQ (Sendust Cores) and customized designs are also available.

※ Sendust: available up to 40μ

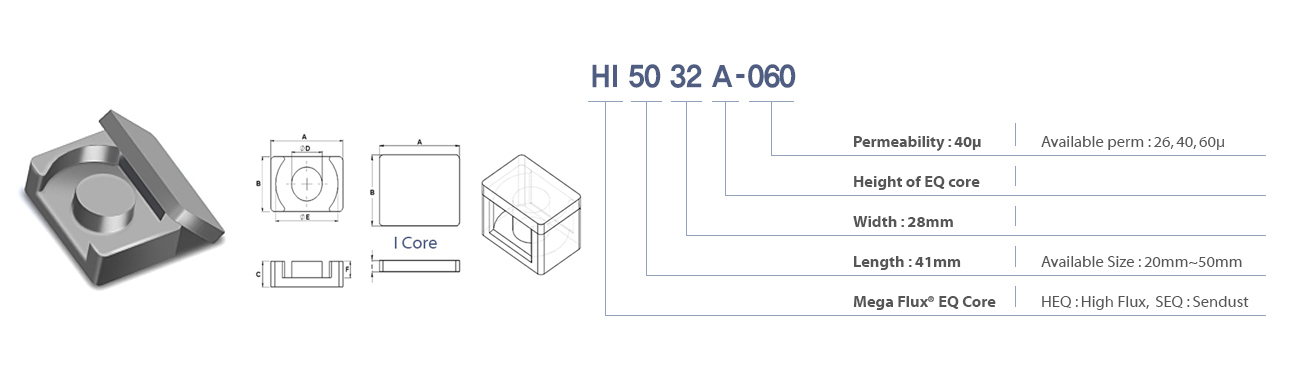

EQ+I型磁粉芯

适用于大电流功率的电感,并且比其他形状更容易实现低高度的电感。同时,还可以保持较大的储能量、高温下的稳定性、较低的磁芯损耗、高工作频率等磁粉芯的基本优点。并且,无需开气隙,有标准化的磁导率可供选择。

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | I | 026μ | 040μ | 060μ | |||

| HEQ 2014A | 20.5 ±0.3 | 14.0 ±0.2 | 8.1 ±0.2 | 8.8 ±0.2 | 18.0 ±0.2 | 5.7 ±0.3 | 3.38 | 0.608 | 59 | 90 | 135 | |

| HI 2014A | 20.5 ±0.3 | 14.0 ±0.2 | 2.4 ±0.2 | |||||||||

| HEQ 2014B | 20.5 ±0.3 | 14.0 ±0.2 | 10.1 ±0.2 | 8.8 ±0.2 | 18.0 ±0.2 | 7.7 ±0.3 | 3.78 | 0.608 | 52 | 81 | 121 | |

| HI 2014A | 20.5 ±0.3 | 14.0 ±0.2 | 2.4 ±0.2 | |||||||||

| HEQ 2619A | 26.5 ±0.3 | 19.0 ±0.2 | 10.1 ±0.2 | 12.0 ±0.2 | 22.6 ±0.3 | 6.8 ±0.3 | 4.11 | 1.198 | 95 | 146 | 220 | |

| HI 2619A | 26.5 ±0.3 | 19.0 ±0.2 | 3.3 ±0.2 | |||||||||

| HEQ 2619B | 26.5 ±0.3 | 19.0 ±0.2 | 12.4 ±0.2 | 12.0 ±0.2 | 22.6 ±0.3 | 9.1 ±0.3 | 4.57 | 1.198 | 85 | 132 | 197 | |

| HI 2619A | 26.5 ±0.3 | 19.0 ±0.2 | 3.3 ±0.2 | |||||||||

| HEQ 3222A | 32.0 ±0.4 | 22.0 ±0.3 | 10.3 ±0.2 | 13.5 ±0.2 | 27.6 ±0.3 | 6.6 ±0.3 | 4.71 | 1.523 | 105 | 162 | 244 | |

| HI 3222A | 32.0 ±0.4 | 22.0 ±0.3 | 3.7 ±0.2 | |||||||||

| HEQ 3222B | 32.0 ±0.4 | 22.0 ±0.3 | 15.2 ±0.2 | 13.5 ±0.2 | 27.6 ±0.3 | 11.5 ±0.3 | 5.69 | 1.523 | 87 | 134 | 202 | |

| HI 3222A | 32.0 ±0.4 | 22.0 ±0.3 | 3.7 ±0.2 | |||||||||

| HEQ 3626A | 36.0 ±0.5 | 26.0 ±0.3 | 17.4 ±0.3 | 14.4 ±0.2 | 32.0 ±0.4 | 13.4 ±0.3 | 6.79 | 1.808 | 87 | 134 | 201 | |

| HI 3626A | 36.0 ±0.5 | 26.0 ±0.3 | 4.0 ±0.3 | |||||||||

| HEQ 4128A | 41.5 ±0.5 | 28.0 ±0.4 | 19.9 ±0.3 | 14.9 ±0.2 | 36.5 ±0.4 | 15.4 ±0.3 | 8.44 | 1.997 | 77 | 119 | 178 | |

| HI 4128A | 41.5 ±0.5 | 28.0 ±0.4 | 4.5 ±0.3 | |||||||||

| HEQ 5032A | 50.0 ±0.6 | 32.0 ±0.4 | 25.0 ±0.4 | 20.0 ±0.3 | 44.0 ±0.5 | 19.5 ±0.4 | 9.44 | 3.141 | 109 | 167 | 251 | |

| HI 5032A | 50.0 ±0.6 | 32.0 ±0.4 | 5.5 ±0.4 | |||||||||

※ Sendust: available up to 40μ

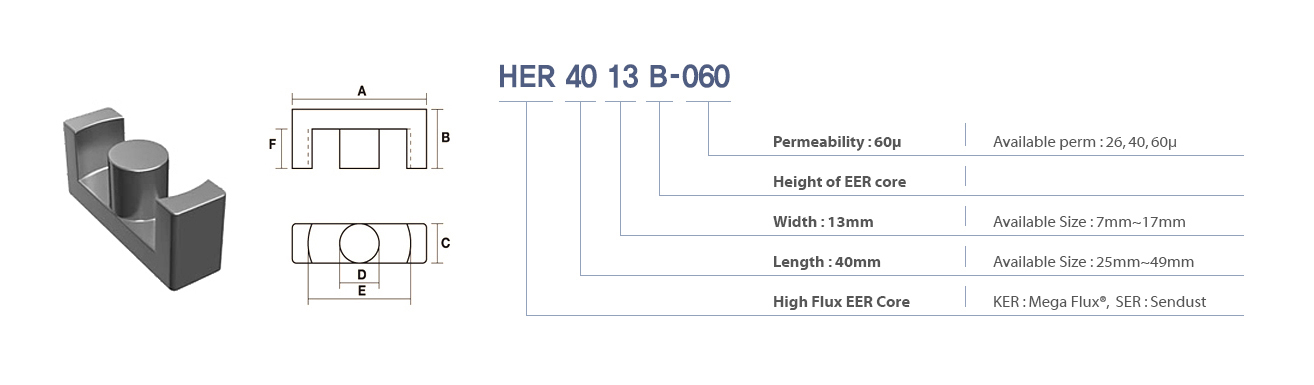

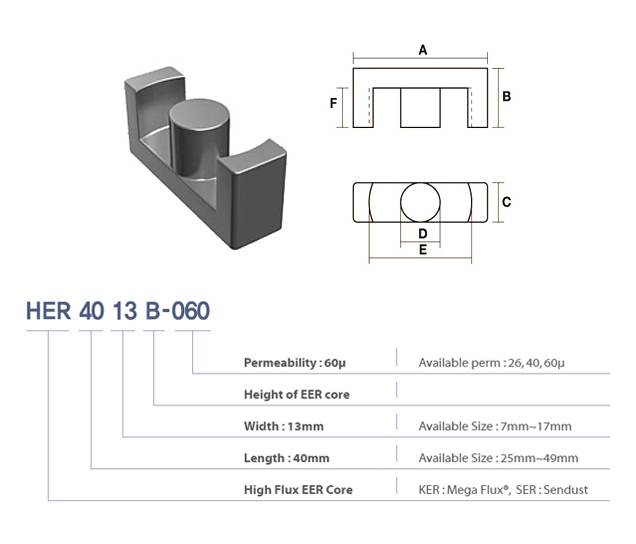

EER型磁粉芯

适用于大电流功率的电感与实现预绕的最佳磁芯形状。同时,还可以保持较大的储能量、高温下的稳定性、较低的磁芯损耗、高工作频率等磁粉芯的基本优点。并且,无需开气隙,有标准化的磁导率可供选择。

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | 026μ | 040μ | 060μ | |||

| HER 2507A | 25.5±0.3 | 9.3±0.2 | 7.5±0.2 | 7.5±0.2 | 19.8±0.2 | 6.2 | 5.1 | 0.45 | 39 | 53 | 73 |

| HER 2507B | 25.5±0.3 | 11.0±0.2 | 7.5±0.2 | 7.5±0.2 | 19.8±0.2 | 7.9 | 5.78 | 0.45 | 34 | 47 | 65 |

| HER 3010A | 30.6±0.3 | 15.8±0.2 | 9.8±0.2 | 9.8±0.2 | 22.0±0.2 | 11 | 8.66 | 0.754 | 38 | 53 | 72 |

| HER 3511A | 35.0±0.4 | 15.8±0.2 | 11.3±0.2 | 11.3±0.2 | 25.6±0.3 | 9.8 | 8.3 | 1.078 | 57 | 78 | 108 |

| HER 3511B | 35.0±0.4 | 20.7±0.2 | 11.3±0.2 | 11.3±0.2 | 25.6±0.3 | 14.7 | 10.27 | 1.078 | 46 | 63 | 87 |

| HER 4013A | 40.0±0.5 | 17.4±0.3 | 13.3±0.3 | 13.3±0.3 | 29.0±0.4 | 10.4 | 9.13 | 1.491 | 72 | 99 | 135 |

| HER 4013B | 40.0±0.5 | 22.4±0.3 | 13.3±0.3 | 13.3±0.3 | 29.0±0.4 | 15.4 | 11.13 | 1.491 | 59 | 81 | 111 |

| HER 4215A | 42.0±0.6 | 22.4±0.4 | 15.5±0.4 | 15.5±0.4 | 29.4±0.5 | 15.4 | 10.64 | 2.026 | 84 | 115 | 158 |

| HER 4215B | 42.0±0.6 | 25.4±0.4 | 15.5±0.4 | 15.5±0.4 | 29.4±0.5 | 18.4 | 11.84 | 2.026 | 75 | 103 | 142 |

| HER 4917A | 49.0±0.7 | 18.8±0.5 | 17.2±0.5 | 17.2±0.5 | 36.5±0.6 | 12.2 | 9.57 | 2.353 | 99 | 136 | 185 |

| HER 4917B | 49.0±0.7 | 24.7±0.5 | 17.2±0.5 | 17.2±0.5 | 36.5±0.6 | 18.1 | 11.93 | 2.353 | 79 | 109 | 149 |

※ HER (High Flux Cores), KER (MegaFlux Cores), SER (Sendust Cores) and customized designs are also available.

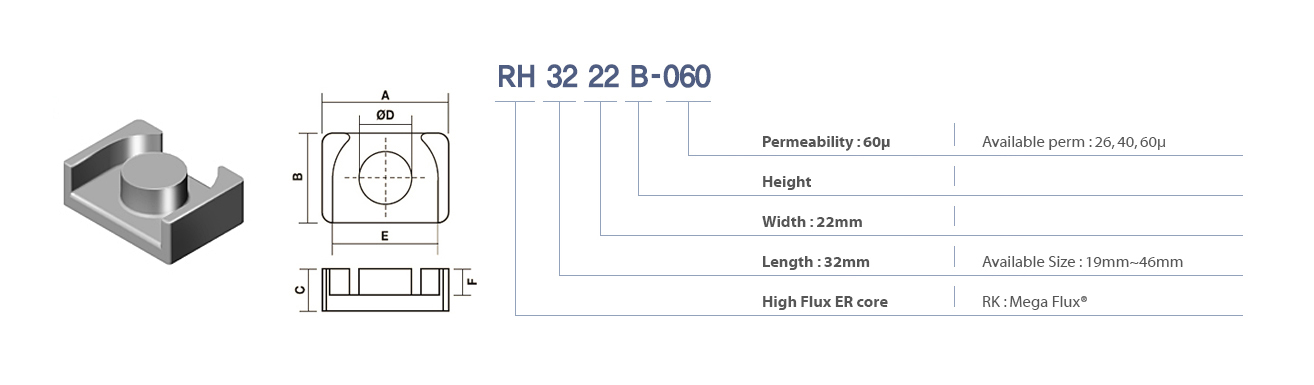

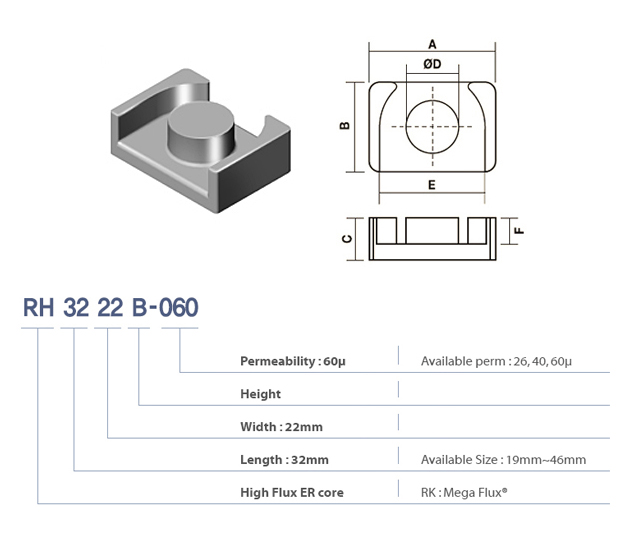

ER型磁粉芯

适用于大电流功率和高度低的电感,并且易于对线圈进出线位置选定,便于构建电路及电感器的安装。同时,还可以保持较大的储能量、高温下的稳定性、较低的磁芯损耗、高工作频率等磁粉芯的基本优点。并且,无需开气隙,有标准化的磁导率可供选择。

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | 026μ | 040μ | 060μ | |||

| RH1911A | 18.8±0.3 | 11.0±0.2 | 6.0±0.2 | 7.4±0.2 | 15.6±0.2 | 4.0±0.2 | 3.54 | 0.425 | 39 | 60 | 90 |

| RH2314A | 23.4±0.3 | 14.0±0.2 | 8.7±0.2 | 9.2±0.2 | 19.4±0.2 | 6.2±0.2 | 4.91 | 0.67 | 45 | 69 | 103 |

| RH2518A | 25.0±0.3 | 18.0±0.2 | 8.4±0.2 | 11.0±0.2 | 21.0±0.3 | 5.4±0.2 | 4.97 | 0.96 | 63 | 97 | 146 |

| RH2518B | 25.0±0.3 | 18.0±0.2 | 10.8±0.2 | 11.0±0.2 | 21.0±0.3 | 7.8±0.2 | 5.93 | 0.96 | 53 | 81 | 122 |

| RH3020A | 30.0±0.4 | 20.0±0.3 | 9.2±0.2 | 12.0±0.2 | 25.6±0.3 | 5.9±0.2 | 5.81 | 1.14 | 64 | 99 | 148 |

| RH3020B | 30.0±0.4 | 20.0±0.3 | 11.8±0.2 | 12.0±0.2 | 25.6±0.3 | 8.5±0.2 | 6.85 | 1.14 | 54 | 84 | 125 |

| RH3222A | 32.0±0.4 | 22.0±0.3 | 10.3±0.2 | 13.5±0.2 | 27.0±0.3 | 6.6±0.2 | 6.25 | 1.43 | 75 | 115 | 172 |

| RH3222B | 32.0±0.4 | 22.0±0.3 | 13.4±0.2 | 13.5±0.2 | 27.0±0.3 | 9.7±0.2 | 7.49 | 1.43 | 62 | 96 | 144 |

| RH3222C | 32.0±0.4 | 22.0±0.3 | 15.2±0.2 | 13.5±0.2 | 27.0±0.3 | 11.5±0.2 | 8.21 | 1.43 | 57 | 88 | 131 |

| RH3624A | 36.2±0.4 | 24.0±0.3 | 11.2±0.2 | 15.0±0.2 | 30.4±0.4 | 7.2±0.2 | 6.78 | 1.77 | 85 | 131 | 197 |

| RH3624B | 36.2±0.4 | 24.0±0.3 | 14.4±0.2 | 15.0±0.2 | 30.4±0.4 | 10.4±0.2 | 8.06 | 1.77 | 72 | 110 | 166 |

| RH4225A | 42.0±0.5 | 25.0±0.3 | 12.3±0.2 | 16.2±0.3 | 35.2±0.4 | 7.9±0.2 | 7.61 | 2.06 | 88 | 136 | 204 |

| RH4225B | 42.0±0.5 | 25.0±0.3 | 15.8±0.2 | 16.2±0.3 | 35.2±0.4 | 11.4±0.2 | 9.01 | 2.06 | 75 | 115 | 172 |

| RH4628A | 46.5±0.6 | 28.0±0.5 | 19.0±0.4 | 14.9±0.4 | 39.3±0.5 | 14.5±0.3 | 9.81 | 2.08 | 69 | 106 | 159 |

※ RH (High Flux Cores), RK (MegaFlux Cores) and customized designs are also available.

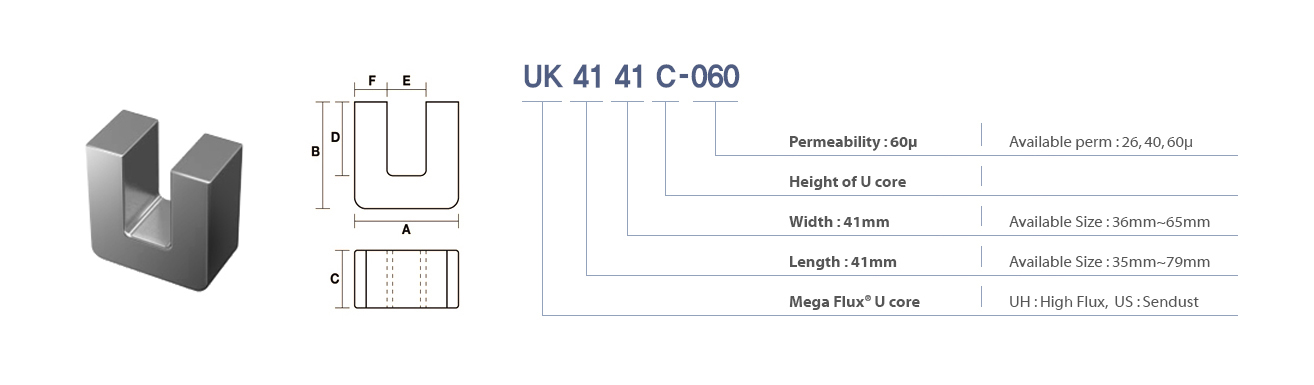

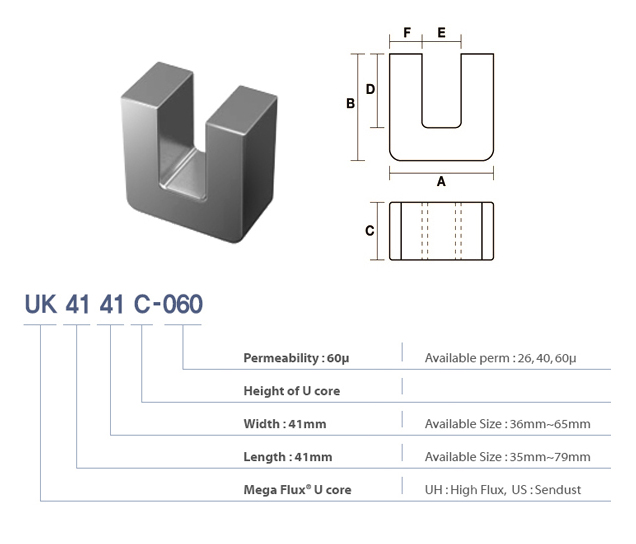

U型磁粉芯

适合用于大功率容量和高感量电感, 并且易于预绕组装,可以实现电路面积的最小化 同时,还可以保持较大的储能量、高温下的稳定性、较低的磁芯损耗、高工作频率等磁粉芯的基本优点。并且,无需开气隙,有标准化的磁导率可供选择。

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | 026μ | 040μ | 060μ | |||

| UK3536A | 35.0±0.5 | 36.0±0.5 | 20.0±0.5 | 25 | 13 | 11.0±0.3 | 16.9 | 2.2 | 43 | 65 | 98 |

| UK3536B | 35.0±0.5 | 36.0±0.5 | 25.0±0.5 | 25 | 13 | 11.0±0.3 | 16.9 | 2.75 | 53 | 82 | 123 |

| UK4141A | 41.0±0.6 | 41.0±0.6 | 20.0±0.5 | 28 | 15 | 13.0±0.3 | 19.3 | 2.6 | 44 | 68 | 102 |

| UK4141B | 41.0±0.6 | 41.0±0.6 | 25.0±0.5 | 28 | 15 | 13.0±0.3 | 19.3 | 3.25 | 55 | 85 | 127 |

| UK4141C | 41.0±0.6 | 41.0±0.6 | 30.0±0.5 | 28 | 15 | 13.0±0.3 | 19.3 | 3.9 | 66 | 102 | 152 |

| UK5251A | 52.0±0.7 | 51.0±0.7 | 25.0±0.5 | 35 | 20 | 16.0±0.4 | 24.3 | 4 | 54 | 83 | 124 |

| UK5251B | 52.0±0.7 | 51.0±0.7 | 30.0±0.5 | 35 | 20 | 16.0±0.4 | 24.3 | 4.8 | 65 | 99 | 149 |

| UK6361A | 63.0±0.8 | 60.5±0.8 | 30.0±0.5 | 41.5 | 25..0 | 19.0±0.4 | 29.1 | 5.7 | 64 | 98 | 148 |

| UK6361B | 63.0±0.8 | 60.5±0.8 | 35.0±0.5 | 41.5 | 25 | 19.0±0.4 | 29.1 | 6.65 | 75 | 115 | 172 |

| UK7965A | 79.0±1.0 | 64.5±1.0 | 30.0±0.5 | 42.5 | 35 | 22.0±0.5 | 32.6 | 6.6 | 66 | 102 | 153 |

| UK7965B | 79.0±1.0 | 64.5±1.0 | 35.0±0.5 | 42.5 | 35 | 22.0±0.5 | 32.6 | 7.7 | 77 | 119 | 178 |

※ UH(High Flux U Core), US(SendustU Core) and customized designs are also available.

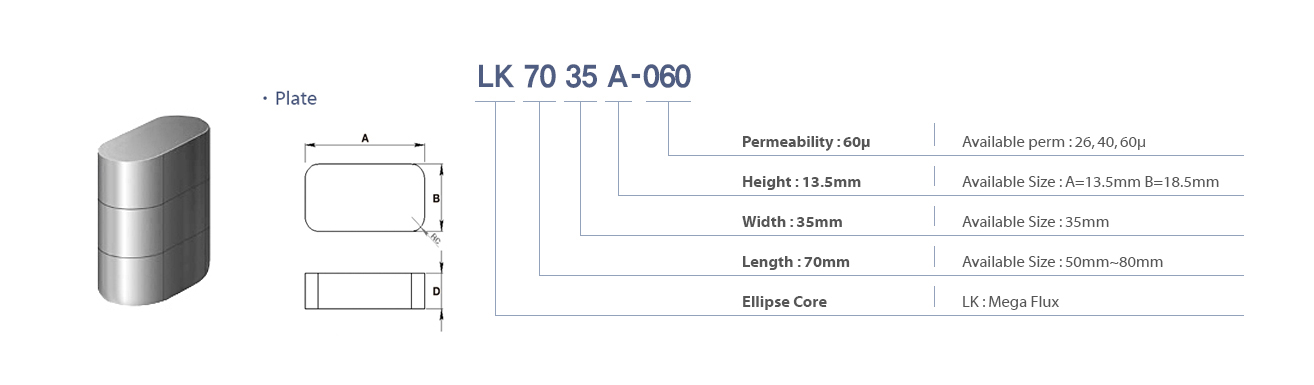

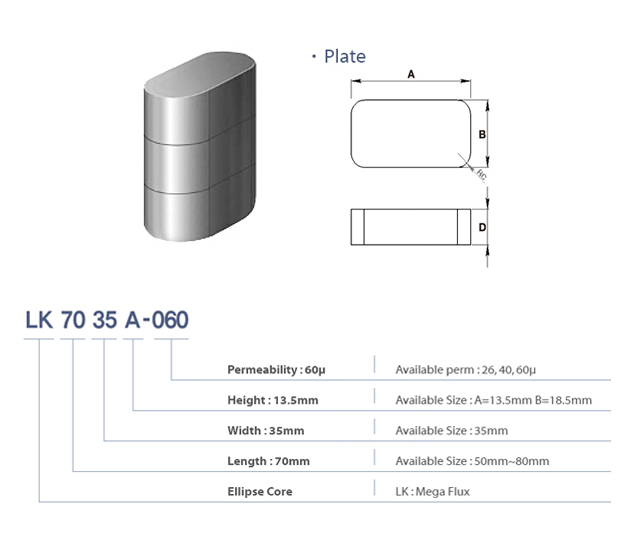

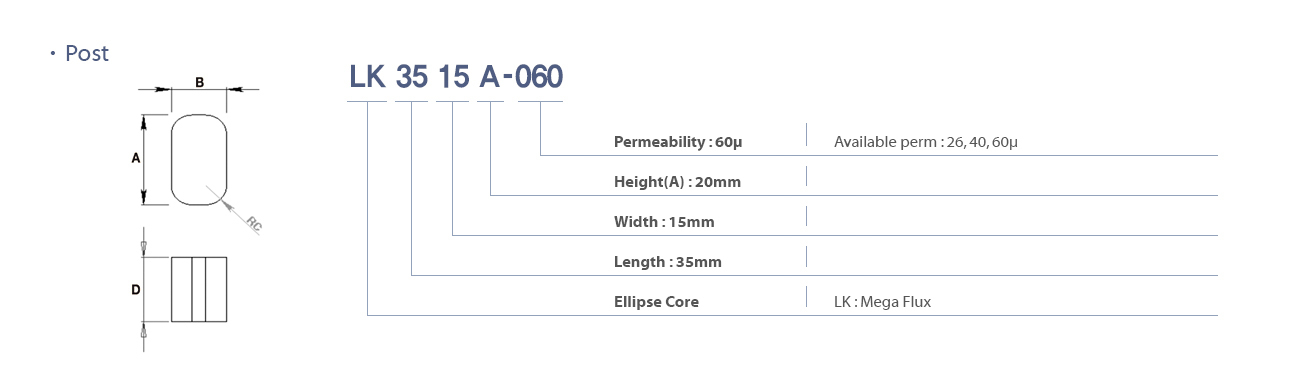

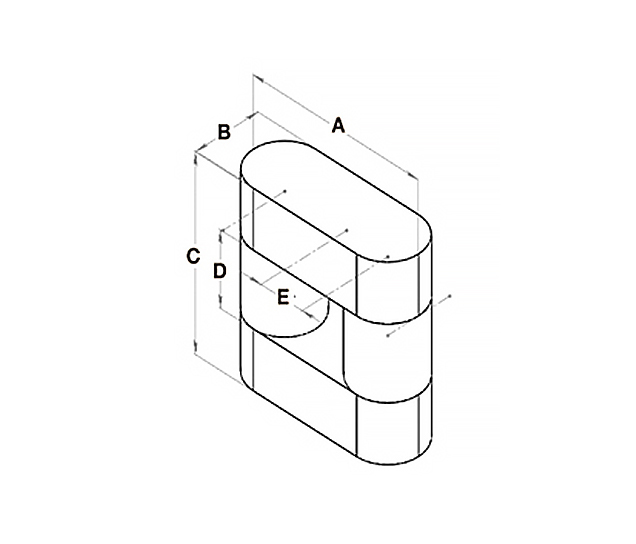

椭圆形磁粉芯

通过与条块等形状磁芯配对使用,可实现各种尺寸及特性的多样化电感。 尤其是作为磁芯的绕线部位,通过形状优化,可以最大限度地减少线圈用量和弯曲部位的绝缘破损,并将绕线部位的直流电阻降至最低,从而实现高效率的大型电感。同时,还可以保持较大的储能量、高温下的稳定性、较低的磁芯损耗、高工作频率等磁粉芯的基本优点。

| Part No. | Dimensions (mm) | Cross Section Area (㎠) | Post | |||

|---|---|---|---|---|---|---|

| A Length |

B Width |

RC Radius |

D Height |

|||

| LK5035A | 50.5±0.5 | 35.3±0.3 | 7.5±0.2 | 13.5±0.2 | 4.77 | LK3515A LK3515B LK3520A LK3520B |

| LK5035B | 50.5±0.5 | 35.3±0.3 | 7.5±0.2 | 18.5±0.2 | 6.52 | |

| LK6035A | 60.5±0.5 | 35.3±0.3 | 7.5±0.2 | 13.5±0.2 | 4.77 | |

| LK6035B | 60.5±0.5 | 35.3±0.3 | 7.5±0.2 | 18.5±0.2 | 6.52 | |

| LK7035A | 70.5±0.5 | 35.3±0.3 | 7.5±0.2 | 13.5±0.2 | 4.77 | |

| LK7035B | 70.5±0.5 | 35.3±0.3 | 7.5±0.2 | 18.5±0.2 | 6.52 | |

| LK8035A | 80.5±0.5 | 35.3±0.3 | 7.5±0.2 | 13.5±0.2 | 4.77 | |

| LK8035B | 80.5±0.5 | 35.3±0.3 | 7.5±0.2 | 18.5±0.2 | 6.52 | |

※LS(Sendust Ellipse Core), LH(High Flux Ellipse Core) and customized designs are also available.

| Part No. | Dimensions (mm) | Cross Section Area (㎠) | Plate | |||

|---|---|---|---|---|---|---|

| A Length |

B Width |

RC Radius |

D Height |

|||

| LK3515A | 35.3 ±0.3 | 15.2 ±0.2 | 7.5 ±0.2 | 20.0 ±0.2 | 4.77 | LK5035A LK6035A LK7035A |

| LK3515B | 35.3 ±0.3 | 15.2 ±0.2 | 7.5 ±0.2 | 25.0 ±0.2 | 4.77 | |

| LK3520A | 35.3 ±0.3 | 20.2 ±0.2 | 7.5 ±0.2 | 20.0 ±0.2 | 6.52 | |

| LK3520B | 35.3 ±0.3 | 20.2 ±0.2 | 7.5 ±0.2 | 25.0 ±0.2 | 6.52 | |

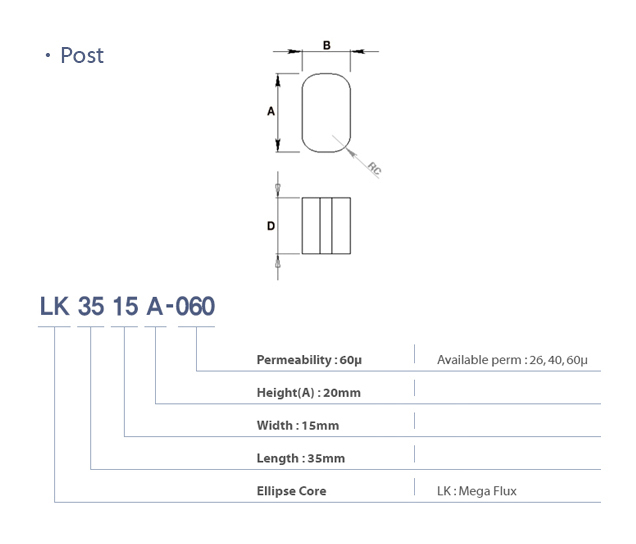

| Part No. | Post | Dimensions (mm) | Path Length (cm) |

Cross Section Area (㎠) |

Window Area (㎠) |

AL value (nH/N2) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part No. | 1 LEG STACK |

A Length |

B Width |

C Height |

D Inner Height |

E Inner Length |

026μ | 040μ | 060μ | ||||

| LK5035A | LK3515A | 2 | 50.5±0.5 | 35.3±0.3 | 67.0±0.5 | 40.0±0.4 | 20.0±0.4 | 16.47 | 4.77 | 8 | 113 | 146 | 218 |

| LK3515B | 2 | 50.5±0.5 | 35.3±0.3 | 77.0±0.5 | 50.0±0.4 | 20.0±0.4 | 18.47 | 4.77 | 10 | 101 | 130 | 195 | |

| LK3515A | 3 | 50.5±0.5 | 35.3±0.3 | 87.0±0.5 | 60.0±0.4 | 20.0±0.4 | 20.47 | 4.77 | 12 | 91 | 117 | 176 | |

| LK5035B | LK3520A | 2 | 50.5±0.5 | 35.3±0.3 | 77.0±0.5 | 40.0±0.4 | 10.0±0.4 | 16.04 | 6.52 | 4 | 158 | 204 | 306 |

| LK3520B | 2 | 50.5±0.5 | 35.3±0.3 | 87.0±0.5 | 50.0±0.4 | 10.0±0.4 | 18.04 | 6.52 | 5 | 141 | 182 | 273 | |

| LK3520A | 3 | 50.5±0.5 | 35.3±0.3 | 97.0±0.5 | 60.0±0.4 | 10.0±0.4 | 20.04 | 6.52 | 6 | 127 | 164 | 245 | |

| LK6035A | LK3515A | 2 | 60.5±0.5 | 35.3±0.3 | 67.0±0.5 | 40.0±0.4 | 30.0±0.4 | 18.47 | 4.77 | 12 | 101 | 130 | 195 |

| LK3515B | 2 | 60.5±0.5 | 35.3±0.3 | 77.0±0.5 | 50.0±0.4 | 30.0±0.4 | 20.47 | 4.77 | 15 | 91 | 117 | 176 | |

| LK3515A | 3 | 60.5±0.5 | 35.3±0.3 | 87.0±0.5 | 60.0±0.4 | 30.0±0.4 | 22.47 | 4.77 | 18 | 83 | 107 | 160 | |

| LK6035B | LK3520A | 2 | 60.5±0.5 | 35.3±0.3 | 77.0±0.5 | 40.0±0.4 | 20.0±0.4 | 18.04 | 6.52 | 8 | 141 | 182 | 273 |

| LK3520B | 2 | 60.5±0.5 | 35.3±0.3 | 87.0±0.5 | 50.0±0.4 | 20.0±0.4 | 20.04 | 6.52 | 10 | 127 | 164 | 245 | |

| LK3520A | 3 | 60.5±0.5 | 35.3±0.3 | 97.0±0.5 | 60.0±0.4 | 20.0±0.4 | 22.04 | 6.52 | 12 | 115 | 149 | 223 | |

| LK7035A | LK3515A | 2 | 70.5±0.5 | 35.3±0.3 | 67.0±0.5 | 40.0±0.4 | 40.0±0.4 | 20.47 | 4.77 | 16 | 91 | 117 | 176 |

| LK3515B | 2 | 70.5±0.5 | 35.3±0.3 | 77.0±0.5 | 50.0±0.4 | 40.0±0.4 | 22.47 | 4.77 | 20 | 83 | 107 | 160 | |

| LK3515A | 3 | 70.5±0.5 | 35.3±0.3 | 87.0±0.5 | 60.0±0.4 | 40.0±0.4 | 24.47 | 4.77 | 24 | 76 | 98 | 147 | |

| LK7035B | LK3520A | 2 | 70.5±0.5 | 35.3±0.3 | 77.0±0.5 | 40.0±0.4 | 30.0±0.4 | 20.04 | 6.52 | 12 | 127 | 164 | 245 |

| LK3520B | 2 | 70.5±0.5 | 35.3±0.3 | 87.0±0.5 | 50.0±0.4 | 30.0±0.4 | 22.04 | 6.52 | 15 | 115 | 149 | 223 | |

| LK3520A | 3 | 70.5±0.5 | 35.3±0.3 | 97.0±0.5 | 60.0±0.4 | 30.0±0.4 | 24.04 | 6.52 | 18 | 106 | 136 | 204 | |

| LK8035A | LK3515A | 2 | 80.5±0.5 | 35.3±0.3 | 67.0±0.5 | 40.0±0.4 | 50.0±0.4 | 22.47 | 4.77 | 16 | 83 | 107 | 160 |

| LK3515B | 2 | 80.5±0.5 | 35.3±0.3 | 77.0±0.5 | 50.0±0.4 | 50.0±0.4 | 24.47 | 4.77 | 20 | 76 | 98 | 147 | |

| LK3515A | 3 | 80.5±0.5 | 35.3±0.3 | 87.0±0.5 | 60.0±0.4 | 50.0±0.4 | 26.47 | 4.77 | 24 | 70 | 91 | 136 | |

| LK8035B | LK3520A | 2 | 80.5±0.5 | 35.3±0.3 | 77.0±0.5 | 40.0±0.4 | 40.0±0.4 | 22.04 | 6.52 | 12 | 115 | 149 | 223 |

| LK3520B | 2 | 80.5±0.5 | 35.3±0.3 | 87.0±0.5 | 50.0±0.4 | 40.0±0.4 | 24.04 | 6.52 | 15 | 106 | 136 | 204 | |

| LK3520A | 3 | 80.5±0.5 | 35.3±0.3 | 97.0±0.5 | 60.0±0.4 | 40.0±0.4 | 26.04 | 6.52 | 18 | 98 | 126 | 189 | |

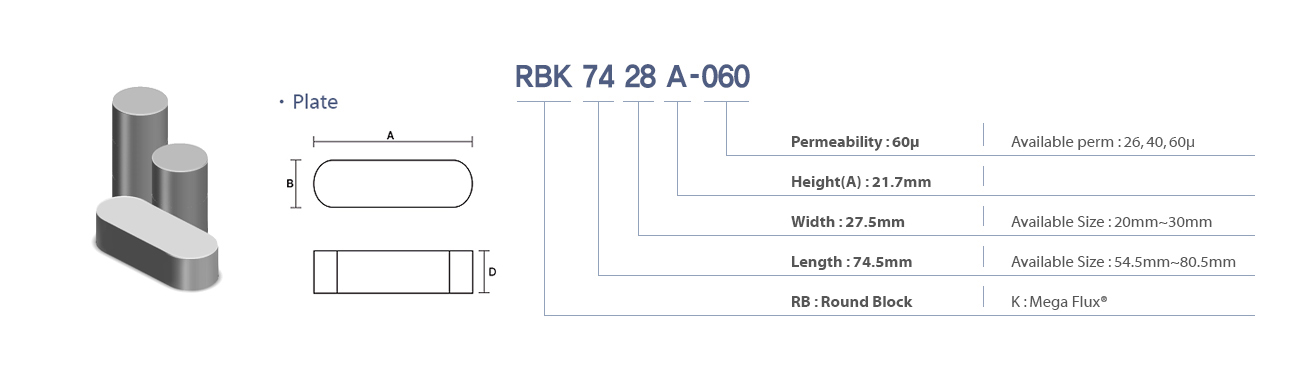

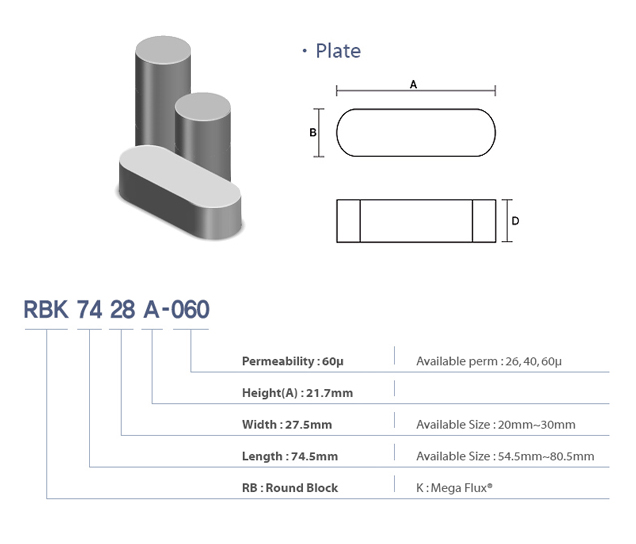

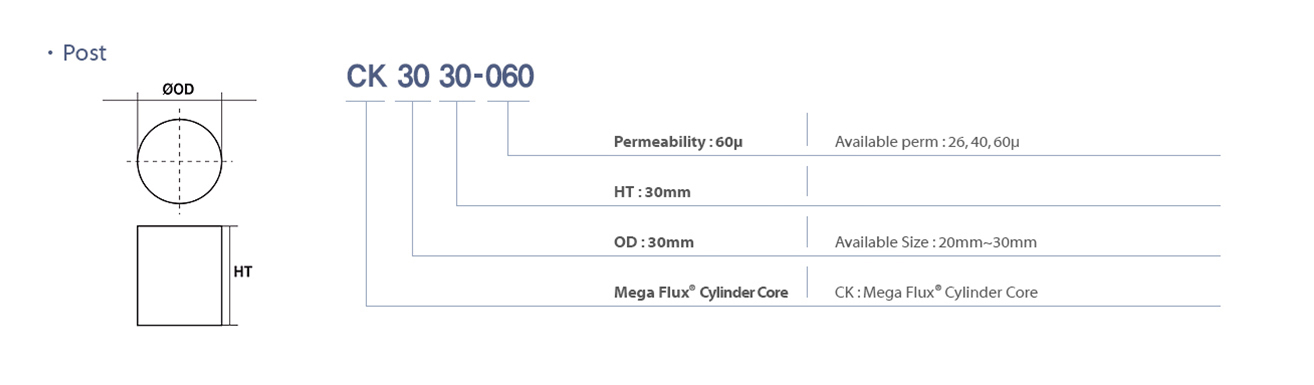

Round Block + 圆柱形磁粉芯

通过与条块等形状配对使用, 可实现各种尺寸和特性的电感。特别是通过椭圆形提升组装部位的磁化特性,可以最大限度地减少线圈用量和弯曲部位的绝缘破损,将绕线部位的直流电阻降至最低,从而可以创建一个高效率地大型电感。同时,还可以保持较大的储能量、高温下的稳定性、较低的磁芯损耗、高工作频率等磁粉芯的基本优点。

| Part No. | Dimensions (mm) | Cross Section Area (㎠) |

Post | |||

|---|---|---|---|---|---|---|

| A Length |

B Width |

RC Radius |

D Height |

|||

| RBK5420A | 54.5±0.5 | 20.2±0.3 | 10.0±0.2 | 15.7±0.2 | 3.14 | CK2020 |

| RBK6424A | 64.5±0.5 | 24.2±0.3 | 12.0±0.2 | 18.8±0.2 | 4.52 | CK2424 |

| RBK6725A | 67.5±0.5 | 25.2±0.3 | 12.5±0.2 | 19.6±0.2 | 4.91 | CK2525 |

| RBK7428A | 74.5±0.5 | 27.5±0.3 | 13.7±0.2 | 21.7±0.2 | 6 | CK2828 |

| RBK8030A | 80.5±0.5 | 30.2±0.3 | 15.0±0.2 | 23.5±0.2 | 7.07 | CK3030 |

| Part No. | Dimensions (mm) | 1Turn length (mm) |

Cross Section Area (㎠) |

Plate | |

|---|---|---|---|---|---|

| OD | HT | ||||

| CK2020 | 20.2±0.3 | 20.2±0.2 | 62.8 | 3.14 | RBK5420-15 |

| CK2424 | 24.2±0.3 | 24.2±0.2 | 75.4 | 4.52 | RBK6424-18 |

| CK2525 | 25.2±0.3 | 25.2±0.2 | 78.5 | 4.91 | RBK6725-19 |

| CK2828 | 27.5±0.3 | 28.0±0.2 | 86.4 | 6 | RBK7428-21 |

| CK3030 | 30.2±0.3 | 30.0±0.2 | 94.2 | 7.07 | RBK8030-23 |

| Part No. | Post | Dimensions (mm) | Path Length (cm) |

Cross Section Area (㎠) |

Window Area (㎠) |

AL value (nH/N2) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part No. | 1 LEG STACK |

A Length |

B Width |

C Height |

D Inner Height |

E Inner Length |

026μ | 040μ | 060μ | ||||

| RBK5420A | CK2020 | 1 | 54 | 20 | 51.4 | 20 | 14 | 12.41 | 3.14 | 2.8 | 99 | 127 | 191 |

| 2 | 54 | 20 | 71.4 | 40 | 14 | 16.41 | 3.14 | 5.6 | 75 | 96 | 144 | ||

| 3 | 54 | 20 | 91.4 | 60 | 14 | 20.41 | 3.14 | 8.4 | 60 | 77 | 116 | ||

| RBK6424A | CK2424 | 1 | 64 | 24 | 61.6 | 24 | 16 | 14.72 | 4.52 | 3.84 | 120 | 154 | 232 |

| 2 | 64 | 24 | 85.6 | 48 | 16 | 19.52 | 4.52 | 7.68 | 90 | 116 | 175 | ||

| 3 | 64 | 24 | 109.6 | 72 | 16 | 24.32 | 4.52 | 11.52 | 72 | 93 | 140 | ||

| RBK6725A | CK2525 | 1 | 67 | 25 | 64.2 | 25 | 17 | 15.41 | 4.91 | 4.25 | 124 | 160 | 240 |

| 2 | 67 | 25 | 89.2 | 50 | 17 | 20.41 | 4.91 | 8.5 | 94 | 121 | 181 | ||

| 3 | 67 | 25 | 114.2 | 75 | 17 | 25.41 | 4.91 | 12.75 | 75 | 97 | 146 | ||

| RBK7428A | CK2828 | 1 | 74 | 27.5 | 71.4 | 28 | 19 | 17.13 | 6 | 5.32 | 136 | 176 | 264 |

| 2 | 74 | 27.5 | 99.4 | 56 | 19 | 22.73 | 6 | 10.64 | 103 | 133 | 199 | ||

| 3 | 74 | 27.5 | 127.4 | 84 | 19 | 28.33 | 6 | 15.96 | 83 | 106 | 160 | ||

| RBK8030A | CK3030 | 1 | 80 | 30 | 77 | 30 | 20 | 18.4 | 7.07 | 6 | 150 | 193 | 290 |

| 2 | 80 | 30 | 107 | 60 | 20 | 24.4 | 7.07 | 12 | 113 | 146 | 218 | ||

| 3 | 80 | 30 | 137 | 90 | 20 | 30.4 | 7.07 | 18 | 91 | 117 | 175 | ||

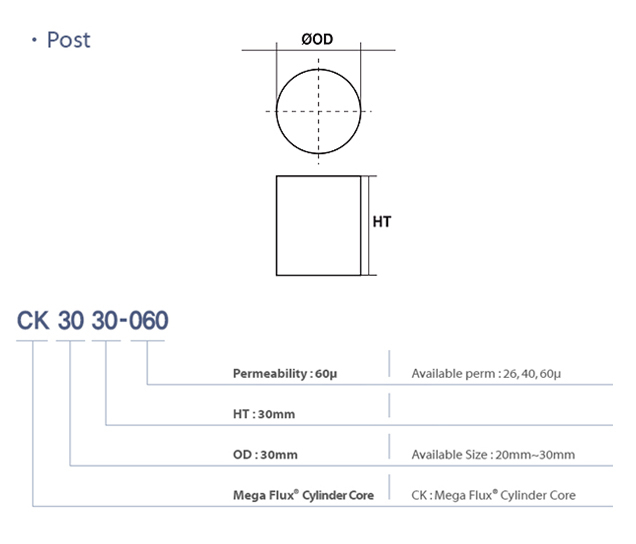

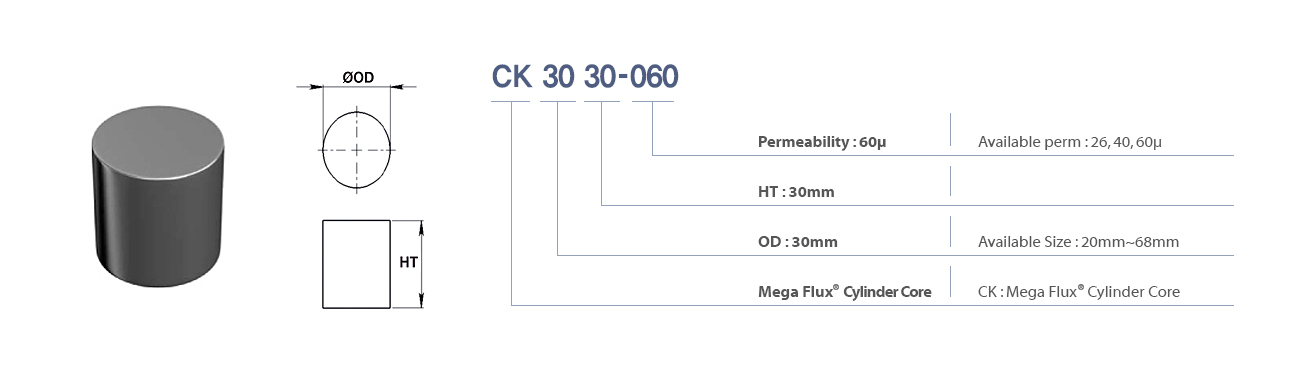

圆柱形磁粉芯

可与条块等形状磁芯配对使用,通过简单的组装,可以设计出各种尺寸和特性的电感。因容易与其他形状配对组装,可以最大限度地减少线圈用量和弯曲部位的绝缘破损,将绕线部位的直流电阻降至最低,从而实现高效率的大型电感。同时,还可以保持较大的储能量、高温下的稳定性、较低的磁芯损耗、高工作频率等磁粉芯的基本优点。

| Part No. | Dimensions (mm) | Path Length (mm) |

Cross Section Area (㎠) |

||||

|---|---|---|---|---|---|---|---|

| OD | HT | 26μ | 040μ | 060μ | |||

| CK2020 | 20.2 ±0.2 | 20.0 ±0.2 | 3.14 | ||||

| CK2424 | 24.0 ±0.2 | 24.0 ±0.2 | 4.5 | ||||

| CK2525 | 25.0 ±0.2 | 25.0 ±0.2 | 4.91 | ||||

| CK2825 | 27.6 ±0.3 | 25.0 ±0.2 | 6 | ||||

| CK2830 | 27.6 ±0.3 | 30.0 ±0.2 | 6 | ||||

| CK3026 | 30.0 ±0.5 | 26.0 ±0.2 | 7.07 | ||||

| CK3030 | 30.0 ±0.5 | 30.0 ±0.2 | 7.07 | ||||

| CK3035 | 30.0 ±0.5 | 34.7 ±0.2 | 7.07 | ||||

| CK3530 | 35.0 ±0.5 | 30.0 ±0.2 | 9.62 | ||||

| CK3735 | 37.0 ±0.5 | 35.25 ±0.2 | 10.75 | ||||

| CK4030 | 40.0 ±0.6 | 30.0 ±0.3 | 12.56 | ||||

| CK4230 | 42.0 ±0.6 | 30.0 ±0.3 | 13.85 | ||||

| CK4630 | 46.0 ±0.6 | 30.0 ±0.3 | 16.61 | ||||

| CK5030 | 50.0 ±0.7 | 30.0 ±0.4 | 19.63 | ||||

| CK5530 | 55.0 ±0.7 | 30.0 ±0.4 | 23.76 | ||||

| CK6030 | 60.0 ±0.8 | 30.0 ±0.5 | 28.27 | ||||

| CK6330 | 63.0 ±0.8 | 30.0 ±0.5 | 31.17 | ||||

| CK6830 | 68.0 ±0.8 | 30.0 ±0.5 | 36.31 | ||||

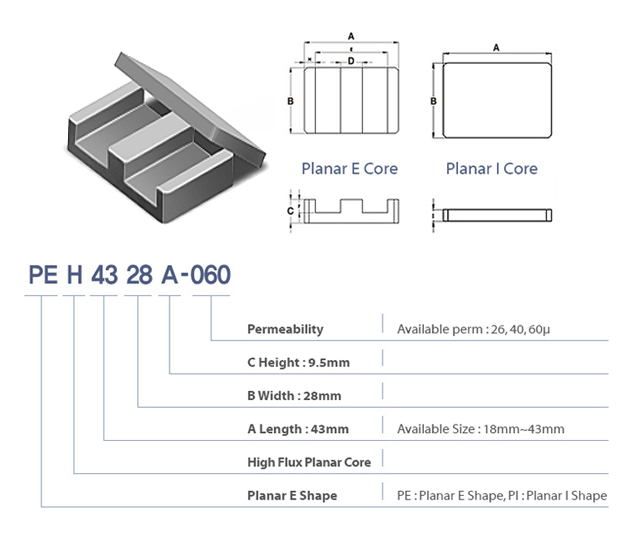

Planar E + I 型磁粉芯

具有厚度较薄的结构优势,为大电流的小型电感提供最佳解决方案。具有几乎为零的磁通量泄露、优异的直流叠加特性、高温下的稳定性和较高的储能量等优点。

| Part NO. | Dimensions | Path Length (cm) |

Cross Section Area |

AL value (nH/n2)±12% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | F(mm) | H, I(mm) | 026μ | 040μ | 060μ | |||

| PEH 1810A | 18.0±0.3 | 10.0±0.2 | 4.0±0.2 | 4.0±0.2 | 14.0±0.2 | 2.0±0.3 | 2.0±0.2 | 2.03 | 0.394 | 63 | 98 | 146 |

| PIH 1810A | 18.0±0.3 | 10.0±0.2 | 2.0±0.2 | |||||||||

| PEH 2216A | 21.8±0.3 | 15.8±0.2 | 5.7±0.2 | 5.0±0.2 | 16.8±0.2 | 3.2±0.3 | 2.5±0.2 | 2.61 | 0.78 | 98 | 150 | 225 |

| PIH 2216A | 21.8±0.3 | 15.8±0.2 | 2.5±0.2 | |||||||||

| PEH 3220A | 31.8±0.3 | 20.3±0.2 | 6.4±0.2 | 6.4±0.2 | 25.4±0.3 | 3.2±0.3 | 3.2±0.2 | 3.55 | 1.283 | 118 | 182 | 272 |

| PIH 3220A | 31.8±0.3 | 20.3±0.2 | 3.2±0.2 | |||||||||

| PEH 3825A | 38.0±0.3 | 25.4±0.2 | 8.2±0.2 | 7.6±0.2 | 30.4±0.3 | 4.4±0.3 | 3.8±0.2 | 4.35 | 1.906 | 143 | 220 | 330 |

| PIH 3825A | 38.0±0.3 | 25.4±0.2 | 3.8±0.2 | |||||||||

| PEH 4328A | 43.2±0.4 | 27.9±0.3 | 9.5±0.2 | 8.2±0.2 | 35.0±0.3 | 5.4±0.3 | 4.1±0.2 | 5.05 | 2.257 | 146 | 225 | 337 |

| PIH 4328A | 43.2±0.4 | 27.9±0.3 | 4.1±0.2 | |||||||||