320, Seunggicheon-ro,

Namdong-gu, Incheon, Korea

Product

Magnetic

Powder Cores

Global No.1, Soft Magnetic Powder Cores

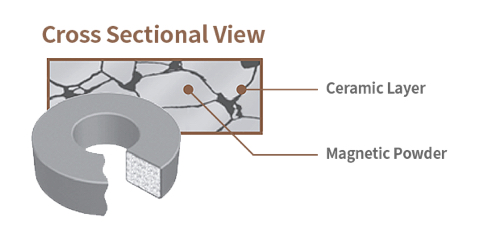

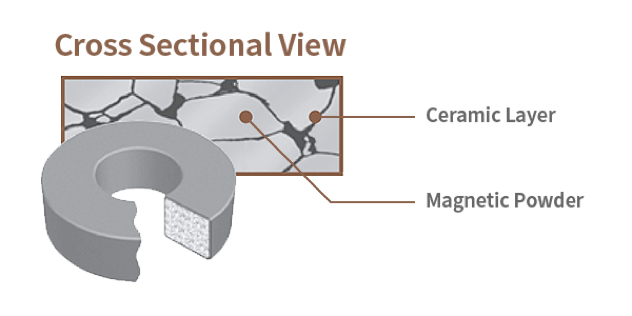

Soft Magnetic Powder Cores, the global No.1 product of Chang Sung Corporation, are used as the main components for power conversion devices across various applications such as Automotive, Server, Solar and Communication, and improve the energy efficiency of all electronics. The technology of Chang Sung always considers a sustainable future.Soft Magnetic Powder Cores made of metal powder have a lower core loss at a high frequency and exhibits almost no magnetic flux leakage due to the presence of small air gaps evenly distributed through the matrix, and thus the product is not easily saturated even at a high direct current.

Applications

Applications

- ∙ Power conversion devices for cars, servers, PV systems, UPS, communications devices, sound devices, measurement equipment, etc.

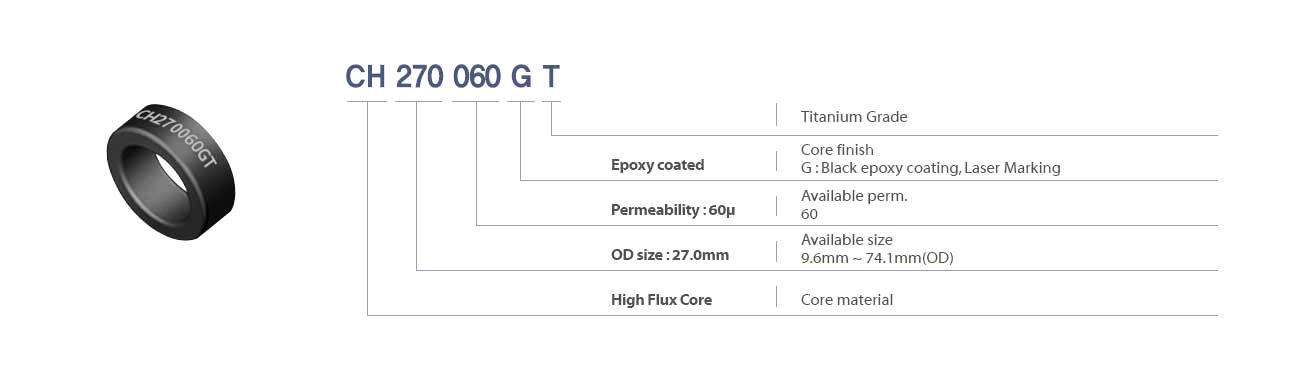

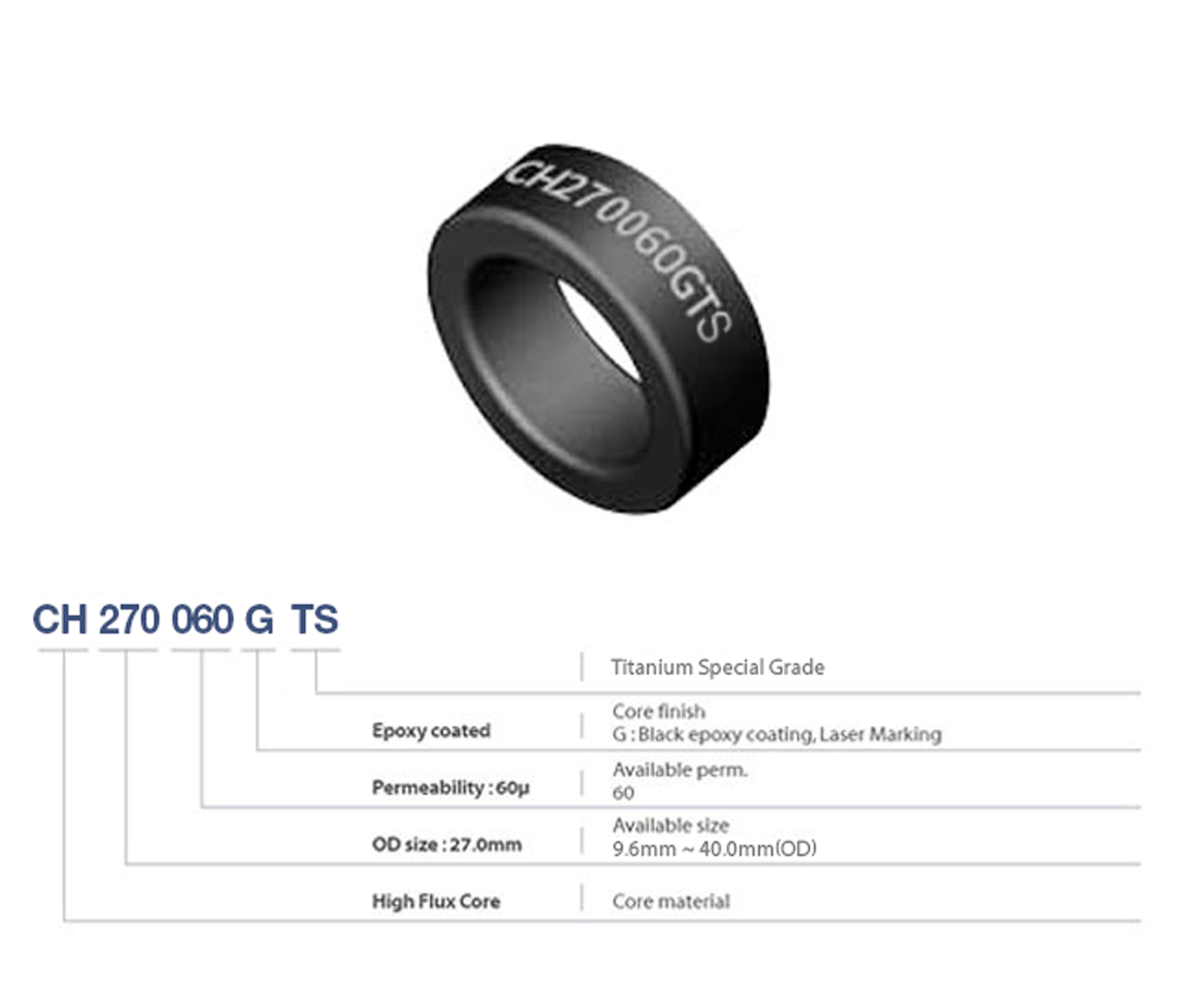

Titanium Grade

High Flux GT Cores

High Flux GT, the world’s best performing magnetic material developed by CSC’s innovative manufacturing process, specializes in the Server and Communication power supply units and the on-board charger for Electric vehicles which require high efficiency. The High Flux GT, one of the flagship achievements of CSC, which has about a 25% lower core loss at 200 kHz and a higher DC bias compared to the original High Flux material, allows its users to optimize their PFC and Output inductor designs.

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||

| 26u | 060u | 125u | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CH097GT | 14 | 32 | 67 | 2.18 | 0.095 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| CH102GT | 14 | 32 | 67 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| CH112GT | 11 | 26 | 54 | 2.69 | 0.091 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| CH127GT | 12 | 27 | 56 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| CH147GT | 14 | 32 | 67 | 3.63 | 0.154 | 14.7 | 8.9 | 5.6 | 15.5 | 8.2 | 6.4 |

| CH166GT | 15 | 35 | 73 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| CH172GT | 19 | 43 | 90 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| CH203GT | 14 | 32 | 67 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| CH229GT | 19 | 43 | 90 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| CH234GT | 22 | 51 | 106 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CH252GT | 27 | 62 | 130 | 6.1 | 0.504 | 25.2 | 14.6 | 10 | 26 | 13.9 | 10.8 |

| CH270GT | 33 | 75 | 156 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CH300GT | 29 | 68 | 141 | 7.27 | 0.652 | 30 | 17.4 | 10.9 | 30.8 | 16.7 | 11.8 |

| CH330GT | 26 | 61 | 127 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CH343GT | 16 | 38 | 79 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CH358GT | 24 | 56 | 117 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CH378GT | 30 | 70 | 145 | 9.4 | 0.867 | 37.8 | 23.2 | 12.5 | 38.7 | 22.3 | 13.4 |

| CH400GT | 35 | 81 | 169 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| CH434GT | 40 | 92 | 191 | 10.74 | 1.308 | 43.4 | 26.4 | 16.2 | 44.3 | 25.5 | 17.1 |

| CH467GT | 59 | 135 | 281 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| CH468GT | 37 | 86 | 179 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| CH488GT | 44 | 101 | 210 | 11.74 | 1.569 | 48.8 | 27.9 | 15.8 | 49.7 | 27 | 16.7 |

| CH508GT | 32 | 73 | 152 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 |

| CH540GT | 44 | 102 | 213 | 12.63 | 1.71 | 54 | 29 | 14.4 | 54.9 | 28.1 | 15.3 |

| CH571GT | 60 | 138 | 288 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 |

| CH572GT | 33 | 75 | 156 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 |

| CH596GT | 54 | 125 | 260 | 14.33 | 2.371 | 59.6 | 34 | 19.5 | 60.6 | 33 | 20.5 |

| CH610GT | 83 | 192 | 400 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 |

| CH640GT | 49 | 113 | 234 | 16.04 | 2.394 | 64 | 40 | 21 | 65.1 | 39 | 22.1 |

| CH680GT | 62 | 143 | 299 | 15.81 | 3.008 | 68 | 36 | 20 | 69.1 | 35 | 21.1 |

| CH740GT | 89 | 206 | 429 | 18.39 | 4.788 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 |

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

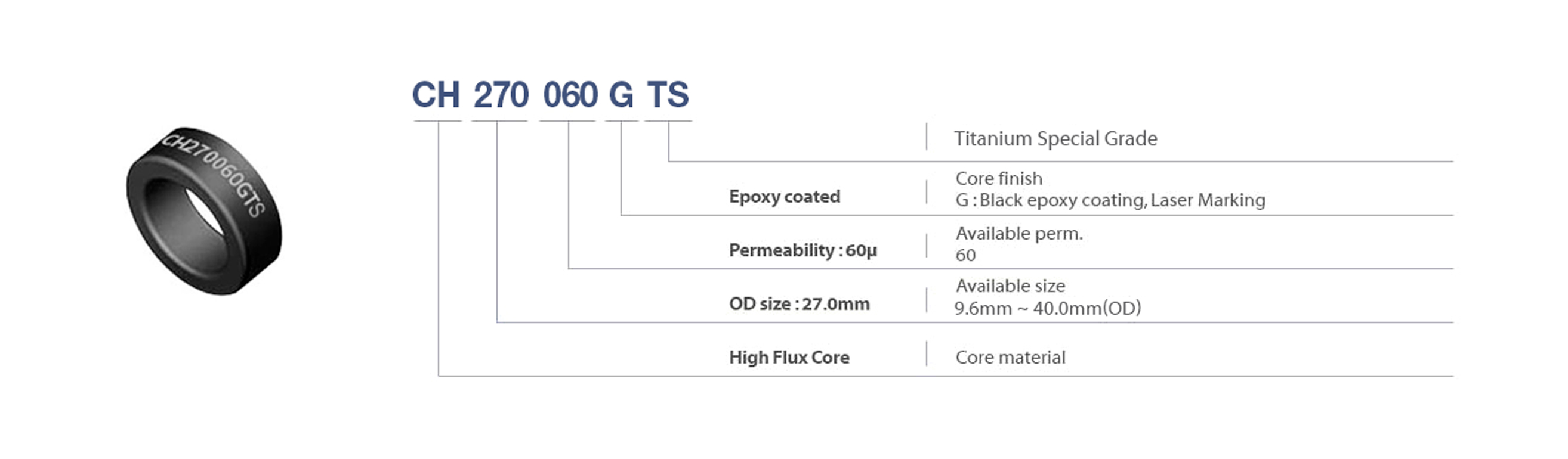

High Flux GTS Cores

High Flux GTS is the next generation of HF GT, specialized in power supply unit that requires high efficiency such as AI computing and Data center. High Flux GTS offers better DC Bias characteristics and 25% lower core loss compared to High Flux GT.

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||

| 060u | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CH097GTS | 32 | 2.18 | 0.095 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| CH102GTS | 32 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| CH112GTS | 26 | 2.69 | 0.091 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| CH127GTS | 27 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| CH147GTS | 32 | 3.63 | 0.154 | 14.7 | 8.9 | 5.6 | 15.5 | 8.2 | 6.4 |

| CH166GTS | 35 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| CH172GTS | 43 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| CH203GTS | 32 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| CH229GTS | 43 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| CH234GTS | 51 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CH252GTS | 62 | 6.1 | 0.504 | 25.2 | 14.6 | 10 | 26 | 13.9 | 10.8 |

| CH270GTS | 75 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CH300GTS | 68 | 7.27 | 0.652 | 30 | 17.4 | 10.9 | 30.8 | 16.7 | 11.8 |

| CH330GTS | 61 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CH343GTS | 38 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CH358GTS | 56 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CH378GTS | 70 | 9.4 | 0.867 | 37.8 | 23.2 | 12.5 | 38.7 | 22.3 | 13.4 |

| CH400GTS | 81 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

Toroidal Cores

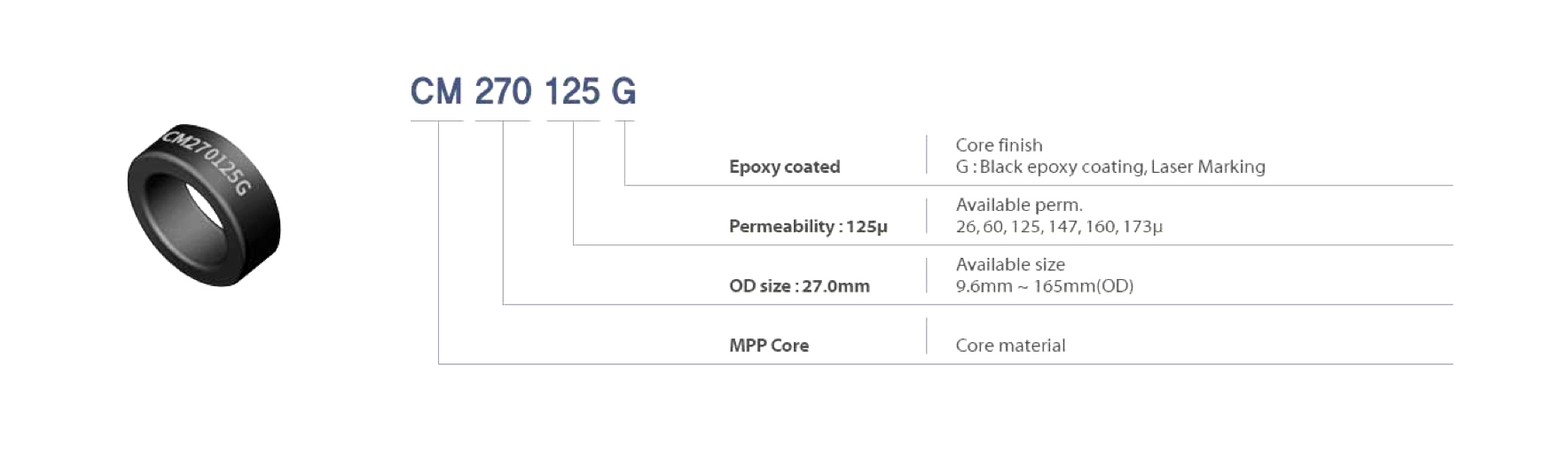

MPP Cores

MPP Cores, a material that provides a low core loss and high permeability, exhibit an excellent temperature and inductance stability under the condition of high DC magnetization or a high DC Bias. It is mainly used as a premium material for high Q filters, loading coils and the DC output inductors for SMPS including EMI/RFI filters in the Aerospace, Defense and Medical fields that require high reliability and stability.

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | |||||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | |||||||||

| 26 | 60 | 125 | 147 | 160 | 173 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CM096 | 11 | 25 | 53 | 63 | 68 | 74 | 2.18 | 0.0752 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 |

| CM097 | 14 | 32 | 66 | 78 | 84 | 92 | 2.18 | 0.0945 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| CM102 | 14 | 32 | 66 | 78 | 84 | 92 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| CM112 | 11 | 26 | 53 | 63 | 68 | 74 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| CM127 | 12 | 27 | 56 | 67 | 72 | 79 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| CM166 | 15 | 35 | 72 | 88 | 92 | 104 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| CM172 | 19 | 43 | 89 | 105 | 114 | 123 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| CM203 | 14 | 32 | 68 | 81 | 87 | 96 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| CM229 | 19 | 43 | 90 | 106 | 115 | 124 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| CM234 | 22 | 51 | 105 | 124 | 135 | 146 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CM270 | 32 | 75 | 157 | 185 | 201 | 217 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CM330 | 28 | 61 | 127 | 150 | 163 | 176 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CM343 | 16 | 38 | 79 | 93 | 101 | 109 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CM358 | 24 | 56 | 117 | 138 | 150 | 162 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CM400 | 35 | 81 | 168 | 198 | 215 | 233 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| CM467 | 59 | 135 | 281 | 33 | 360 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 | |

| CM468 | 37 | 86 | 178 | 210 | 228 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 | |

| CM508 | 32 | 73 | 152 | 179 | 195 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 | |

| CM571 | 60 | 138 | 287 | 306 | 333 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 | |

| CM572 | 33 | 75 | 156 | 185 | 200 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 | |

| CM610 | 83 | 192 | 400 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 | |||

| CM740 | 89 | 206 | 429 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 | |||

| CM777 | 30 | 68 | 142 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 | |||

| CM778 | 37 | 85 | 178 | 20 | 2.27 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 | |||

| CM1013 | 40 | 92 | 192 | 24.27 | 2.97 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 | |||

| CM1016 | 47 | 112 | 228 | 24.27 | 3.52 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 | |||

| CM1027 | 80 | 184 | 384 | 24.27 | 5.94 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 | |||

| CM1033 | 94 | 224 | 456 | 24.27 | 7.04 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 | |||

| CM1320 | 54 | 124 | 259 | 32.42 | 5.35 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 | |||

| CM1325 | 68 | 156 | 325 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 | |||

| CM1333 | 88 | 202 | 422 | 32.42 | 8.72 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 | |||

| CM1340 | 108 | 248 | 518 | 32.42 | 10.69 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 | |||

| CM1625 | 80 | 184 | 384 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 | |||

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

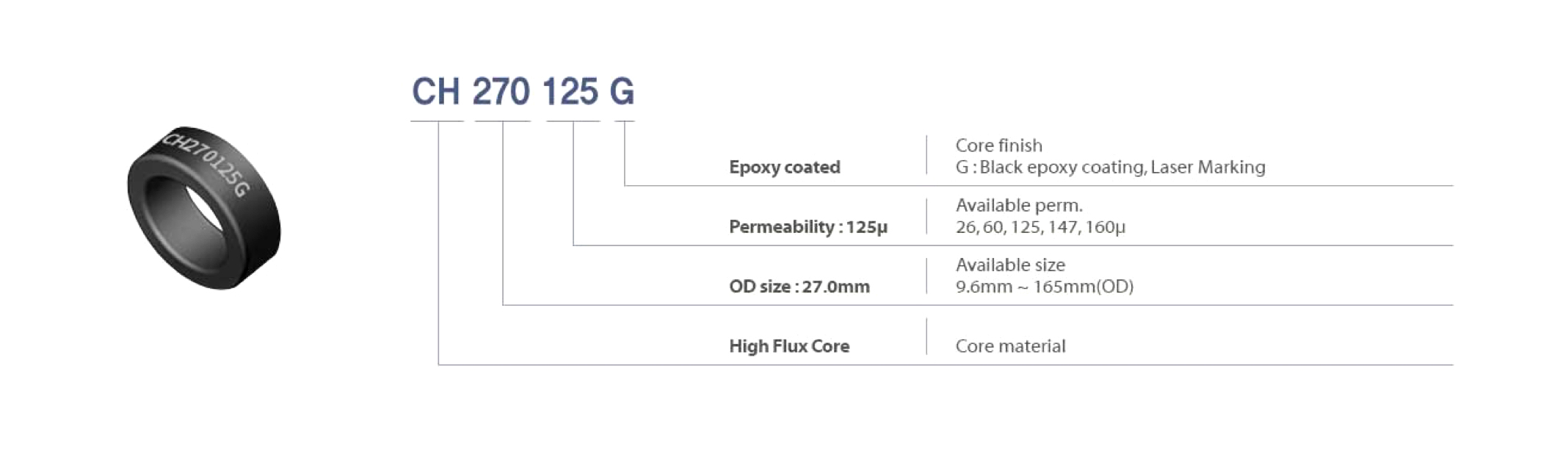

High Flux Cores

High Flux Cores with a 15,000 Gauss saturation level have a higher energy storage capacity and permeability compared to the gapped ferrites or iron powder cores with a similar size. The excellent DC Bias characteristics and low core loss of the High Flux Cores reduce the inductor size and number of winding turns and provide superior magnetic properties. CSC’s High Flux Cores will be a wise choice for applications such as PFC inductors, switching regulator inductors, in-line noise filters, pulse transformers and fly-back transformers.

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||||

| 26 | 60 | 125 | 147 | 160 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CH096 | 11 | 25 | 53 | 63 | 68 | 2.18 | 0.0752 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 |

| CH097 | 14 | 32 | 66 | 78 | 84 | 2.18 | 0.0945 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| CH102 | 14 | 32 | 66 | 78 | 84 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| CH112 | 11 | 26 | 53 | 63 | 68 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| CH127 | 12 | 27 | 56 | 67 | 72 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| CH166 | 15 | 35 | 72 | 88 | 92 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| CH172 | 19 | 43 | 89 | 105 | 114 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| CH203 | 14 | 32 | 68 | 81 | 87 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| CH229 | 19 | 43 | 90 | 106 | 115 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| CH234 | 22 | 51 | 105 | 124 | 135 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CH270 | 32 | 75 | 157 | 185 | 201 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CH330 | 28 | 61 | 127 | 150 | 163 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CH343 | 16 | 38 | 79 | 93 | 101 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CH358 | 24 | 56 | 117 | 138 | 150 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CH400 | 35 | 81 | 168 | 198 | 215 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| CH467 | 59 | 135 | 281 | 33 | 360 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| CH468 | 37 | 86 | 178 | 210 | 228 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| CH508 | 32 | 73 | 152 | 179 | 195 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 |

| CH571 | 60 | 138 | 287 | 306 | 333 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 |

| CH572 | 33 | 75 | 156 | 185 | 200 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 |

| CH610 | 83 | 192 | 400 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 | ||

| CH740 | 89 | 206 | 429 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 | ||

| CH777 | 30 | 68 | 142 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 | ||

| CH778 | 37 | 85 | 178 | 20 | 2.27 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 | ||

| CH1013 | 40 | 92 | 192 | 24.27 | 2.97 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 | ||

| CH1016 | 47 | 112 | 228 | 24.27 | 3.52 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 | ||

| CH1027 | 80 | 184 | 384 | 24.27 | 5.94 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 | ||

| CH1033 | 94 | 224 | 456 | 24.27 | 7.04 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 | ||

| CH1320 | 54 | 124 | 259 | 32.42 | 5.35 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 | ||

| CH1325 | 68 | 156 | 325 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 | ||

| CH1333 | 88 | 202 | 422 | 32.42 | 8.72 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 | ||

| CH1340 | 108 | 248 | 518 | 32.42 | 10.69 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 | ||

| CH1625 | 80 | 184 | 384 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 | ||

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

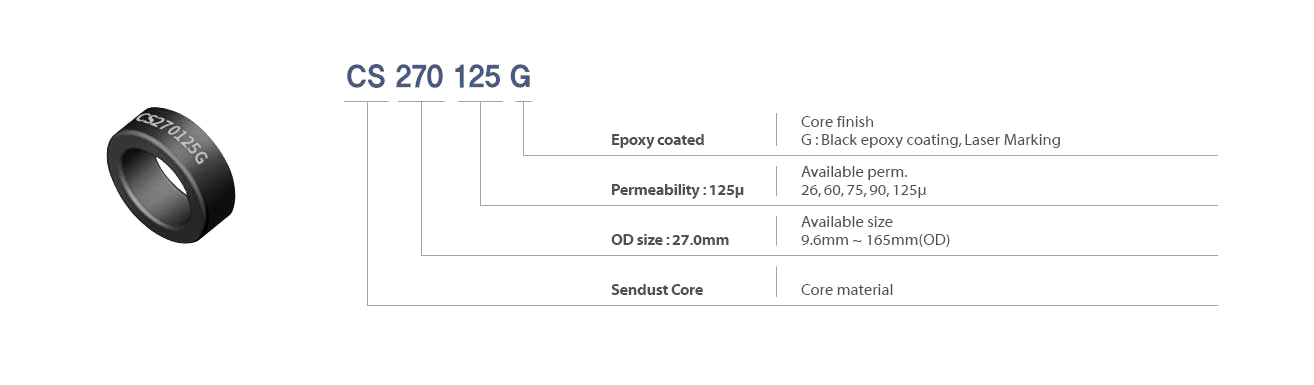

Sendust Cores

Due to the near-zero magnetostriction, Sendust Cores are ideal for removing the audible noise from filter inductors. The core loss of Sendust Cores is much lower than that of the iron powder cores. In particular, Sendust E Cores provides a higher energy storage capacity than the gapped ferrite E cores. The gap loss and eddy current loss can be minimized using the Sendust E Cores. The Sendust core is a smart choice for PFC circuits. Other key applications include the switching regulator inductors, in-line noise filters, pulse transformer and fly-back transformers.

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||||

| 26 | 60 | 75 | 90 | 125 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CS096 | 11 | 25 | 32 | 38 | 53 | 2.18 | 0.0752 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 |

| CS097 | 14 | 32 | 40 | 48 | 66 | 2.18 | 0.0945 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| CS102 | 14 | 32 | 40 | 48 | 66 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| CS112 | 11 | 26 | 32 | 38 | 53 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| CS127 | 12 | 27 | 34 | 40 | 56 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| CS166 | 15 | 35 | 43 | 52 | 72 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| CS172 | 19 | 43 | 53 | 64 | 89 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| CS203 | 14 | 32 | 41 | 49 | 68 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| CS229 | 19 | 43 | 54 | 65 | 90 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| CS234 | 22 | 51 | 63 | 76 | 105 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CS270 | 32 | 75 | 94 | 113 | 157 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CS330 | 28 | 61 | 76 | 91 | 127 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CS343 | 16 | 38 | 47 | 57 | 79 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CS358 | 24 | 56 | 70 | 84 | 117 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CS400 | 35 | 81 | 101 | 121 | 168 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| CS467 | 59 | 135 | 169 | 202 | 281 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| CS468 | 37 | 86 | 107 | 128 | 178 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| CS508 | 32 | 73 | 91 | 109 | 152 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 |

| CS571 | 60 | 138 | 172 | 206 | 287 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 |

| CS572 | 33 | 75 | 94 | 112 | 156 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 |

| CS610 | 83 | 192 | 240 | 288 | 400 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 |

| CS740 | 89 | 206 | 257 | 309 | 429 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 |

| CS777 | 30 | 68 | 85 | 102 | 124 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 |

| CS778 | 37 | 85 | 107 | 128 | 178 | 20 | 2.27 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 |

| CS1013 | 40 | 92 | 115 | 138 | 445 | 24.27 | 2.97 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 |

| CS1016 | 47 | 112 | 137 | 134 | 540 | 24.27 | 3.52 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 |

| CS1027 | 80 | 184 | 231 | 277 | 890 | 24.27 | 5.94 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 |

| CS1033 | 94 | 224 | 273 | 328 | 1080 | 24.27 | 7.04 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 |

| CS1320 | 54 | 124 | 155 | 186 | 1064 | 32.42 | 5.35 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 |

| CS1325 | 68 | 156 | 195 | 234 | 1332 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 |

| CS1333 | 88 | 202 | 253 | 304 | 1730 | 32.42 | 8.72 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 |

| CS1340 | 108 | 248 | 311 | 373 | 2128 | 32.42 | 10.69 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 |

| CS1625 | 80 | 184 | 230 | 277 | 2280 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 |

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

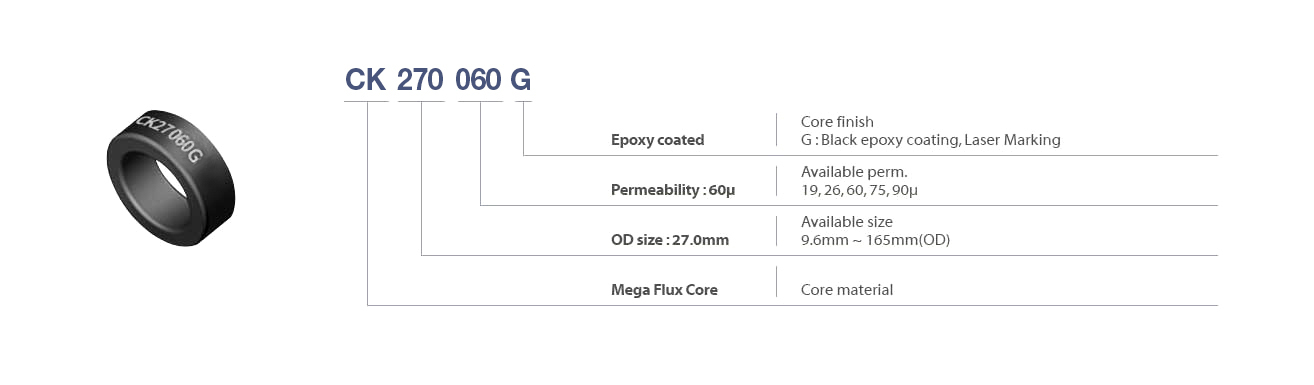

Mega Flux Cores

CSC is the first company in the world that developed the magnetic powder cores made of Fe and Si. The magnetic flux density of this innovative Mega Flux Cores is 16,000 Gauss, which is higher than the other materials such as the High Flux Cores of 15,000 Gauss and the Sendust Cores of 10,000 Gauss. The excellent DC Bias characteristics provide the best solution for advanced applications such as the Buck/Boost inductors for high power supply systems, Smoothing chokes for inverters and inductors for Electric vehicles. Mega Flux Cores have a significantly lower core loss than the iron powder cores or Fe-Si strip cores and also exhibit an excellent thermal stability without thermal aging.

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||||

| 19 | 26 | 60 | 75 | 90 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| CK096 | 11 | 25 | 31 | 38 | 2.18 | 0.075 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 | |

| CK097 | 14 | 32 | 40 | 48 | 2.18 | 0.095 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 | |

| CK112 | 11 | 26 | 32 | 38 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 | |

| CK127 | 12 | 27 | 34 | 40 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 | |

| CK166 | 15 | 35 | 43 | 52 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 | |

| CK172 | 19 | 43 | 53 | 64 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 | |

| CK203 | 14 | 32 | 41 | 49 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 | |

| CK229 | 19 | 43 | 54 | 65 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 | |

| CK234 | 16 | 22 | 51 | 63 | 76 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| CK270 | 24 | 32 | 75 | 94 | 113 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| CK330 | 19 | 28 | 61 | 76 | 91 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| CK343 | 12 | 16 | 38 | 47 | 57 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| CK358 | 18 | 24 | 56 | 70 | 84 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| CK400 | 26 | 35 | 81 | 101 | 121 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| CK467 | 43 | 59 | 135 | 169 | 202> | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| CK468 | 27 | 37 | 86 | 107 | 128 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| CK508 | 23 | 32 | 73 | 91 | 109 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 |

| CK571 | 44 | 60 | 138 | 172 | 206 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 |

| CK572 | 24 | 33 | 75 | 94 | 112 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 |

| CK610 | 61 | 83 | 192 | 240 | 288 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 |

| CK740 | 65 | 89 | 206 | 257 | 309 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 |

| CK777 | 22 | 30 | 68 | 85 | 102 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 |

| CK778 | 27 | 37 | 85 | 107 | 128 | 20 | 2.77 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 |

| CK1013 | 29 | 40 | 92 | 192 | 24.27 | 2.97 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 | |

| CK1016 | 35 | 47 | 112 | 228 | 24.27 | 3.52 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 | |

| CK1027 | 58 | 80 | 184 | 384 | 24.27 | 5.94 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 | |

| CK1033 | 70 | 94 | 224 | 456 | 24.27 | 7.04 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 | |

| CK1320 | 39 | 54 | 124 | 259 | 32.42 | 5.35 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 | |

| CK1325 | 49 | 68 | 156 | 325 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 | |

| CK1333 | 64 | 88 | 202 | 422 | 32.42 | 8.72 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 | |

| CK1340 | 79 | 108 | 248 | 518 | 32.42 | 10.69 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 | |

| CK1625 | 58 | 80 | 184 | 384 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 | |

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

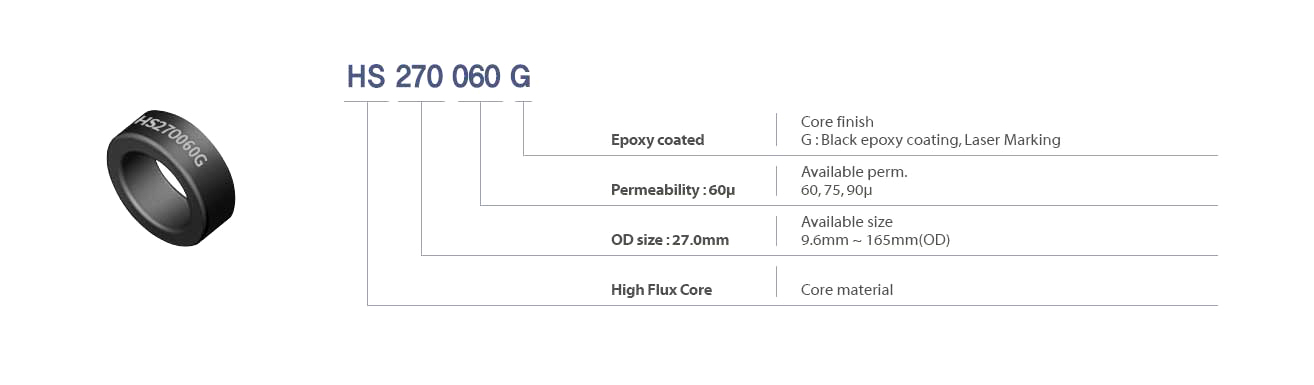

HS Cores

HS Cores have a better DC Bias characteristic and lower core loss than Sendust Cores. It provides an economical solution for a variety of high-efficiency applications such as the high-power Desktop PCs, Server PCs, Automotive and Solar power generation. In addition, it can be a good alternative to the amorphous cores as it exhibits an excellent thermal stability without the thermal aging problem found in other soft magnetic powder cores.

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||

| 60 | 75 | 90 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| HS096 | 25 | 32 | 38 | 2.18 | 0.0752 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 |

| HS097 | 32 | 40 | 48 | 2.18 | 0.0945 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 |

| HS102 | 32 | 40 | 48 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 |

| HS112 | 26 | 32 | 38 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 |

| HS127 | 27 | 34 | 40 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 |

| HS166 | 35 | 43 | 52 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 |

| HS172 | 43 | 53 | 64 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 |

| HS203 | 32 | 41 | 49 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 |

| HS229 | 43 | 54 | 65 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 |

| HS234 | 51 | 63 | 76 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 |

| HS270 | 75 | 94 | 113 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| HS330 | 61 | 76 | 91 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| HS343 | 38 | 47 | 57 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| HS358 | 56 | 70 | 84 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| HS400 | 81 | 101 | 121 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| HS467 | 135 | 169 | 202 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| HS468 | 86 | 107 | 128 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| HS508 | 73 | 91 | 109 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 |

| HS571 | 138 | 172 | 206 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 |

| HS572 | 75 | 94 | 112 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 |

| HS610 | 192 | 240 | 288 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 |

| HS740 | 206 | 257 | 309 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 |

| HS777 | 68 | 85 | 102 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 |

| HS778 | 85 | 107 | 128 | 20 | 2.27 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 |

| HS1013 | 92 | 24.27 | 2.972 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 | ||

| HS1016 | 112 | 24.27 | 3.522 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 | ||

| HS1027 | 184 | 24.27 | 5.944 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 | ||

| HS1033 | 224 | 24.27 | 7.044 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 | ||

| HS1320 | 124 | 32.42 | 5.347 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 | ||

| HS1325 | 156 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 | ||

| HS1333 | 202 | 32.42 | 8.717 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 | ||

| HS1340 | 248 | 32.42 | 10.694 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 | ||

| HS1625 | 184 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 | ||

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

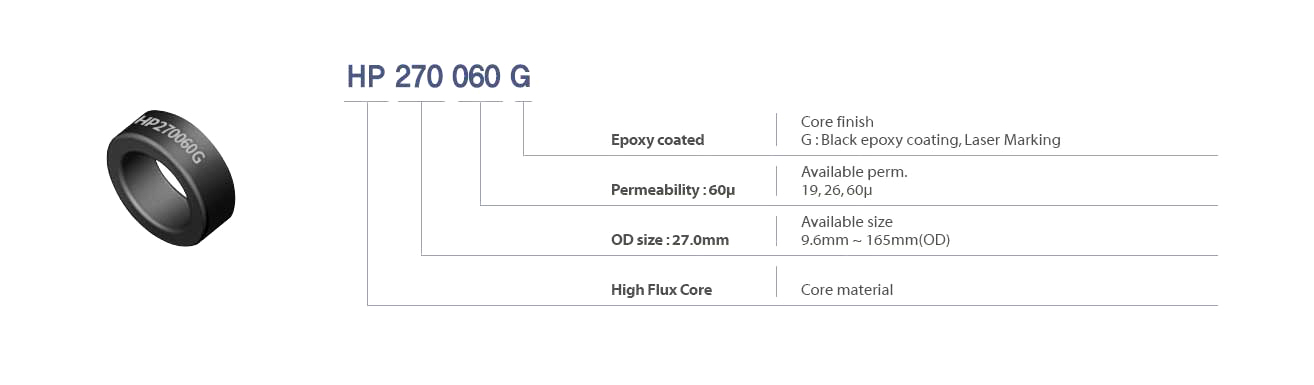

HP Cores

With near-zero magnetostriction, HP Cores are ideal for eliminating the audible noise from inductors. In particular, the core loss of 19u and 26u is much lower than that of other materials and even lower than that of MPP. HP 19u and 26u provide suitable solutions for applications requiring high efficiency such as UPS and ESS. HP 60u is the least-lossed material capable of minimizing the temperature rise of devices at a high frequency. It is suitable for PFC and the Output inductors of the small- and medium-sized power servers and EV charger applications and can be a good alternative to the amorphous cores.

| Part No | Nominal Inductance(nH/N²) | Path Length (cm) | Cross Section Area (cm²) | Dimensions(mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Finish Dimensions | After Finish Dimensions | ||||||||||

| OD(mm) | ID(mm) | HT(mm) | OD(mm) | ID(mm) | HT(mm) | ||||||

| 19 | 26 | 60 | MAX | MIN | MAX | MAX | MIN | MAX | |||

| HP096 | 11 | 25 | 2.18 | 0.0752 | 9.65 | 4.78 | 3.18 | 10.29 | 4.27 | 3.81 | |

| HP097 | 14 | 32 | 2.18 | 0.0945 | 9.65 | 4.78 | 3.96 | 10.29 | 4.27 | 4.57 | |

| HP102 | 14 | 32 | 2.38 | 0.1 | 10.16 | 5.08 | 3.96 | 10.8 | 4.57 | 4.57 | |

| HP112 | 11 | 26 | 2.69 | 0.0906 | 11.18 | 6.35 | 3.96 | 11.9 | 5.89 | 4.72 | |

| HP127 | 12 | 27 | 3.12 | 0.114 | 12.7 | 7.62 | 4.75 | 13.46 | 6.99 | 5.51 | |

| HP166 | 25 | 35 | 4.11 | 0.192 | 16.51 | 10.16 | 6.35 | 17.4 | 9.53 | 7.11 | |

| HP172 | 19 | 43 | 4.14 | 0.232 | 17.27 | 9.65 | 6.35 | 18.03 | 9.02 | 7.11 | |

| HP203 | 14 | 32 | 5.09 | 0.226 | 20.32 | 12.7 | 6.35 | 21.1 | 12.07 | 7.11 | |

| HP229 | 19 | 43 | 5.67 | 0.331 | 22.86 | 13.97 | 7.62 | 23.62 | 13.39 | 8.38 | |

| HP234 | 22 | 51 | 5.88 | 0.388 | 23.57 | 14.4 | 8.89 | 24.3 | 13.77 | 9.7 | |

| HP270 | 24 | 33 | 75 | 6.35 | 0.654 | 26.92 | 14.73 | 11.18 | 27.7 | 14.1 | 11.99 |

| HP330 | 19 | 26 | 61 | 8.15 | 0.672 | 33.02 | 19.94 | 10.67 | 33.83 | 19.3 | 11.61 |

| HP343 | 12 | 16 | 38 | 8.95 | 0.454 | 34.29 | 23.37 | 8.89 | 35.2 | 22.6 | 9.83 |

| HP358 | 18 | 24 | 56 | 8.98 | 0.678 | 35.81 | 22.35 | 10.46 | 36.7 | 21.5 | 11.28 |

| HP400 | 26 | 35 | 81 | 9.84 | 1.072 | 39.88 | 24.13 | 14.48 | 40.7 | 23.3 | 15.37 |

| HP467 | 43 | 59 | 135 | 10.74 | 1.99 | 46.74 | 24.13 | 18.03 | 47.6 | 23.3 | 18.92 |

| HP468 | 27 | 37 | 86 | 11.63 | 1.34 | 46.74 | 28.7 | 15.24 | 47.6 | 27.9 | 16.13 |

| HP508 | 23 | 32 | 12.73 | 1.25 | 50.8 | 31.75 | 13.46 | 51.7 | 30.9 | 14.35 | |

| HP571 | 44 | 60 | 12.5 | 2.29 | 57.15 | 26.39 | 15.24 | 58 | 25.6 | 16.1 | |

| HP572 | 24 | 33 | 14.3 | 1.444 | 57.15 | 35.56 | 13.97 | 58 | 34.7 | 14.86 | |

| HP610 | 61 | 83 | 14.37 | 3.675 | 62 | 32.6 | 25 | 63.1 | 31.37 | 26.27 | |

| HP740 | 61 | 89 | 18.38 | 5.04 | 74.1 | 45.3 | 35 | 75.2 | 44.07 | 36.27 | |

| HP777 | 22 | 29 | 20 | 1.77 | 77.8 | 49.23 | 12.7 | 78.9 | 48 | 13.97 | |

| HP778 | 27 | 37 | 20 | 2.27 | 77.8 | 49.23 | 15.9 | 78.9 | 48 | 17.02 | |

| HP1013 | 29 | 40 | 24.27 | 2.972 | 101.6 | 57.2 | 13.6 | 103.1 | 55.7 | 14.9 | |

| HP1016 | 35 | 49 | 24.27 | 3.522 | 101.6 | 57.2 | 16.5 | 103.1 | 55.7 | 17.8 | |

| HP1027 | 58 | 80 | 24.27 | 5.944 | 101.6 | 57.2 | 27.2 | 103.1 | 55.7 | 28.5 | |

| HP1033 | 71 | 97 | 24.27 | 7.044 | 101.6 | 57.2 | 33 | 103.1 | 55.7 | 34.3 | |

| HP1320 | 39 | 54 | 32.42 | 5.347 | 132.5 | 78.6 | 20.3 | 134.2 | 77 | 21.7 | |

| HP1325 | 49 | 68 | 32.42 | 6.71 | 132.5 | 78.6 | 25.4 | 134.2 | 77 | 26.8 | |

| HP1333 | 64 | 88 | 32.42 | 8.717 | 132.5 | 78.6 | 33 | 134.2 | 77 | 34.4 | |

| HP1340 | 79 | 107 | 32.42 | 10.694 | 132.5 | 78.6 | 40.6 | 134.2 | 77 | 42 | |

| HP1625 | 58 | 80 | 38.65 | 9.46 | 165 | 88.9 | 25.4 | 167.2 | 86.9 | 27.3 | |

※ Custom heights are also available.

※ Max. Heights are normally limited to 1.5 times of the original heights.

Shaped Cores

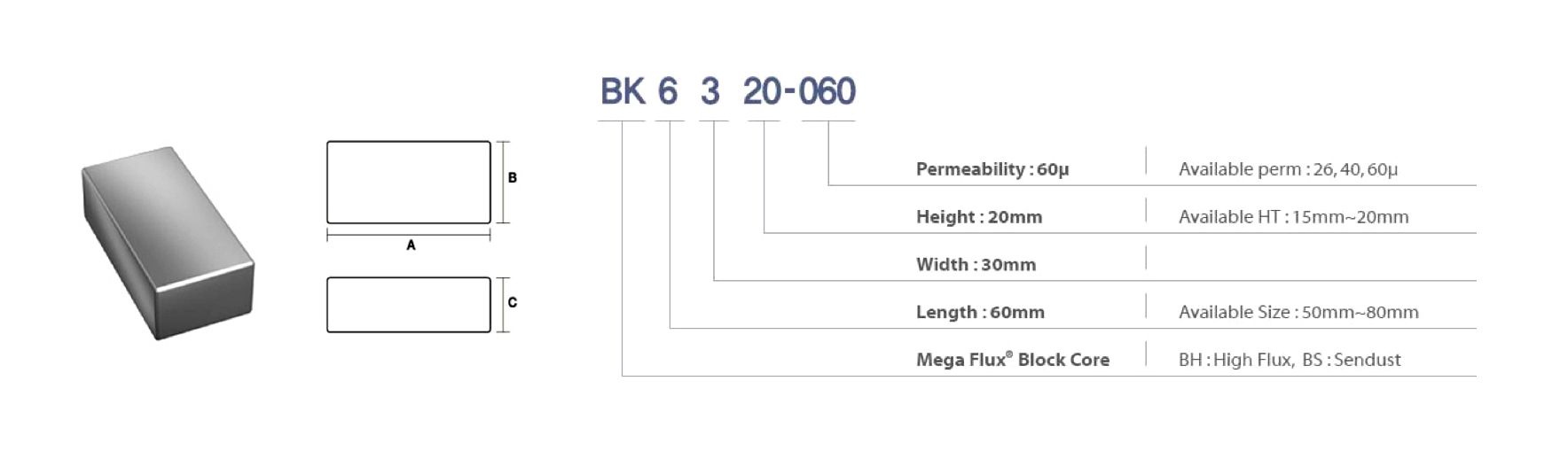

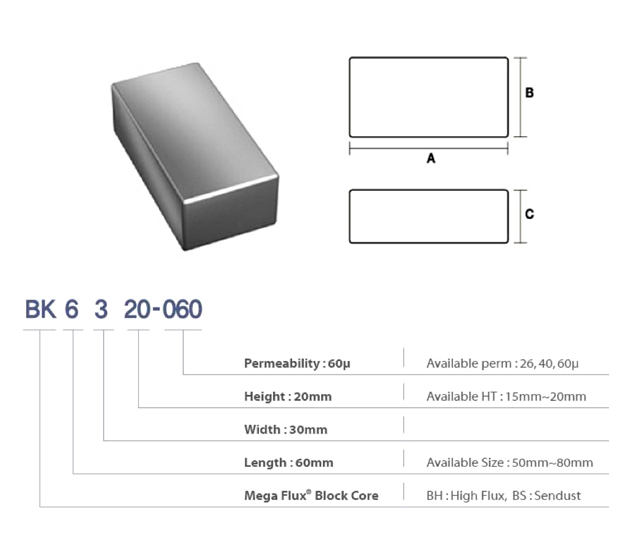

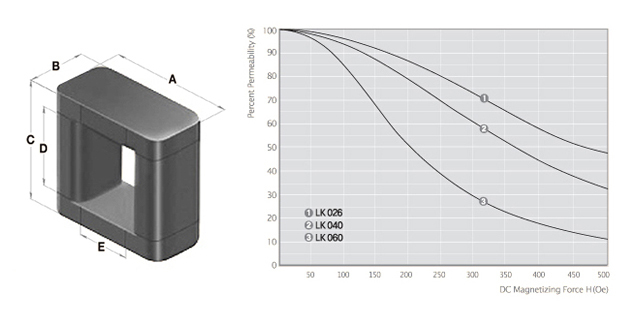

Block Cores

Various inductor structures can be realized according to the user’s convenience, and high-difficulty winding and assembly-type inductors also can be easily implemented. In addition, the basic advantages of the soft magnetic powder cores such as a high energy storage capacity, high temperature stability, low core loss and a high operating frequency can be maintained as they are.

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | 4PCS AL value (nH/N²)±12% | ||||

|---|---|---|---|---|---|---|---|---|

| A Length | B Width | C Height | 026μ | 040μ | 060μ | |||

| BK5315 | 50.5±0.5 | 30.3±0.3 | 15±0.2 | 18.71 | 4.5 | 95 | 121 | 181 |

| BK5320 | 50.5±0.5 | 30.3±0.3 | 20±0.2 | 18.28 | 6 | 130 | 165 | 247 |

| BK6315 | 60.5±0.5 | 30.3±0.3 | 15±0.2 | 22.71 | 4.5 | 79 | 100 | 149 |

| BK6320 | 60.5±0.5 | 30.3±0.3 | 20±0.2 | 22.28 | 6 | 107 | 135 | 203 |

| BK7315 | 70.5±0.5 | 30.3±0.3 | 15±0.2 | 26.71 | 4.5 | 67 | 85 | 127 |

| BK7320 | 70.5±0.5 | 30.3±0.3 | 20±0.2 | 26.28 | 6 | 91 | 115 | 172 |

| BK8315 | 80.5±0.5 | 30.3±0.3 | 15±0.2 | 30.71 | 4.5 | 58 | 74 | 110 |

| BK8320 | 80.5±0.5 | 30.3±0.3 | 20±0.2 | 30.28 | 6 | 78 | 100 | 149 |

| BK9315 | 90.5±0.5 | 30.3±0.3 | 15±0.2 | 34.71 | 4.5 | 51 | 65 | 98 |

| BK9320 | 90.5±0.5 | 30.3±0.3 | 20±0.2 | 34.28 | 6 | 68 | 88 | 132 |

| BK5020A | 50.5±0.5 | 20.3±0.3 | 20±0.2 | 18.28 | 4 | 87 | 110 | 165 |

| BK6020A | 60.5±0.5 | 20.3±0.3 | 20±0.2 | 22.28 | 4 | 71 | 90 | 135 |

| BK6020B | 60.5±0.5 | 20.3±0.3 | 25±0.2 | 21.85 | 5 | 91 | 115 | 173 |

| BK7020A | 70.5±0.5 | 20.3±0.3 | 20±0.2 | 26.28 | 4 | 60 | 77 | 115 |

| BK7020B | 70.5±0.5 | 20.3±0.3 | 25±0.2 | 25.85 | 5 | 77 | 97 | 146 |

| BK8020A | 80.5±0.5 | 20.3±0.3 | 20±0.2 | 30.28 | 4 | 52 | 66 | 100 |

| BK8020B | 80.5±0.5 | 20.3±0.3 | 25±0.2 | 29.85 | 5 | 66 | 84 | 126 |

※ BS(Sendust Block Core), BH(HighFlux Core) and customized designs are also available.

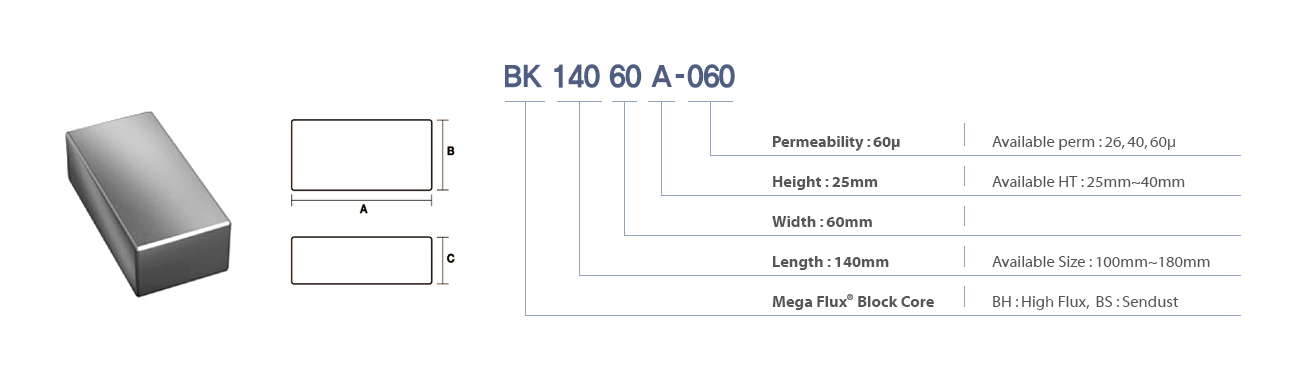

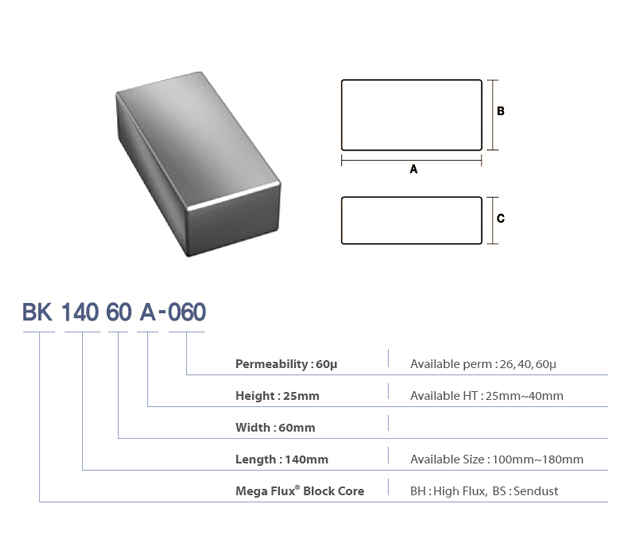

Big Block Cores

It is possible to assemble larger capacity inductor cores and to realize the various structures of the inductors tailored to the user’s convenience. And the high-difficulty winding and assembly-type inductors can also be easily implemented. In addition, the basic advantages of the soft magnetic powder cores such as high energy storage capacity, high temperature stability, low core loss and a high operating frequency can be maintained as they are.

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | 4PCS AL value (nH/N²)±12% | ||||

|---|---|---|---|---|---|---|---|---|

| A Length | B Width | C Height | 026μ | 040μ | 060μ | |||

| BK10060A | 100.6±1.0 | 60.5±0.6 | 25±0.6 | 37.85 | 15 | 157 | 199 | 299 |

| BK10060B | 100.6±1.0 | 60.5±0.6 | 30±0.6 | 37.42 | 18 | 191 | 242 | 362 |

| BK10060C | 100.6±1.0 | 60.5±0.6 | 35±0.8 | 37 | 21 | 225 | 285 | 428 |

| BK10060D | 100.6±1.0 | 60.5±0.6 | 40±0.8 | 36.57 | 24 | 260 | 330 | 495 |

| BK11060A | 110.6±1.0 | 60.5±0.6 | 25±0.6 | 41.85 | 15 | 142 | 180 | 270 |

| BK11060B | 110.6±1.0 | 60.5±0.6 | 30±0.6 | 41.42 | 18 | 172 | 218 | 327 |

| BK11060C | 110.6±1.0 | 60.5±0.6 | 35±0.8 | 41 | 21 | 203 | 257 | 386 |

| BK11060D | 110.6±1.0 | 60.5±0.6 | 40±0.8 | 40.57 | 24 | 235 | 297 | 446 |

| BK12060A | 120.6±1.0 | 60.5±0.6 | 25±0.6 | 45.85 | 15 | 130 | 164 | 246 |

| BK12060B | 120.6±1.0 | 60.5±0.6 | 30±0.6 | 45.42 | 18 | 157 | 199 | 299 |

| BK12060C | 120.6±1.0 | 60.5±0.6 | 35±0.8 | 45 | 21 | 185 | 234 | 352 |

| BK12060D | 120.6±1.0 | 60.5±0.6 | 40±0.8 | 44.57 | 24 | 214 | 270 | 406 |

| BK14060A | 140.6±1.0 | 60.5±0.6 | 25±0.6 | 53.85 | 15 | 111 | 140 | 210 |

| BK14060B | 140.6±1.0 | 60.5±0.6 | 30±0.6 | 53.42 | 18 | 134 | 169 | 254 |

| BK14060C | 140.6±1.0 | 60.5±0.6 | 35±0.8 | 53 | 21 | 157 | 199 | 299 |

| BK14060D | 140.6±1.0 | 60.5±0.6 | 40±0.8 | 52.57 | 24 | 181 | 229 | 344 |

| BK16060A | 160.6±1.0 | 60.5±0.6 | 25±0.6 | 61.85 | 15 | 96 | 122 | 183 |

| BK16060B | 160.6±1.0 | 60.5±0.6 | 30±0.6 | 61.42 | 18 | 116 | 147 | 221 |

| BK16060C | 160.6±1.0 | 60.5±0.6 | 35±0.8 | 61 | 21 | 137 | 173 | 259 |

| BK16060D | 160.6±1.0 | 60.5±0.6 | 40±0.8 | 60.57 | 24 | 157 | 199 | 299 |

| BK18060A | 180.6±1.0 | 60.5±0.6 | 25±0.6 | 69.85 | 15 | 85 | 108 | 162 |

| BK18060B | 180.6±1.0 | 60.5±0.6 | 30±0.6 | 69.42 | 18 | 103 | 130 | 195 |

| BK18060C | 180.6±1.0 | 60.5±0.6 | 35±0.8 | 69 | 21 | 121 | 153 | 229 |

| BK18060D | 180.6±1.0 | 60.5±0.6 | 40±0.8 | 68.57 | 24 | 139 | 176 | 264 |

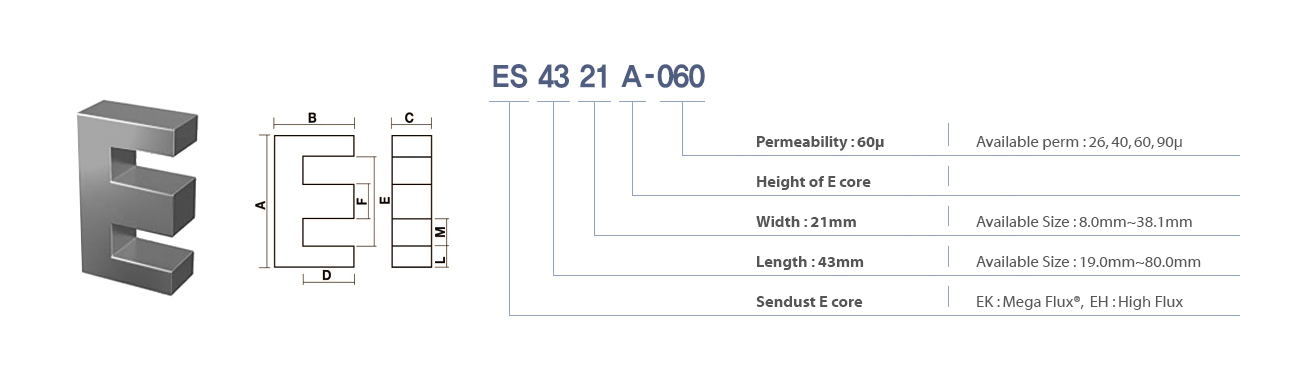

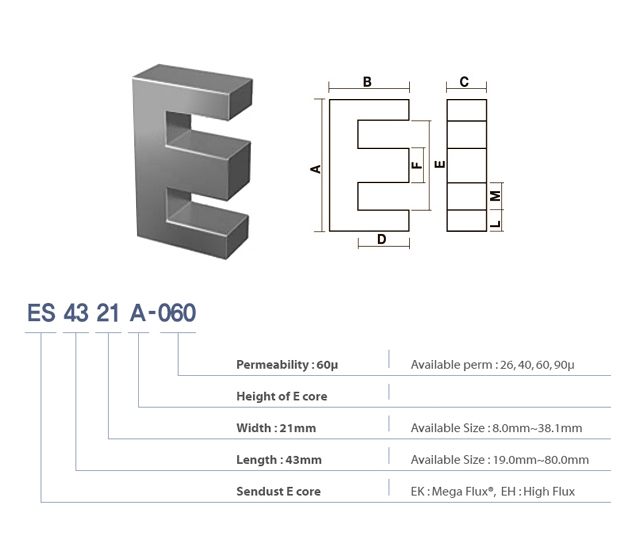

E Cores

It is easy to secure high inductance and easy to make inductors with a lower height than other core shapes with the same characteristics. In addition, the basic advantages of the soft magnetic powder cores such as high energy storage capacity, high temperature stability, low core loss and high operating frequency can be maintained as they are.

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D(min) | E(min) | F | L(nom) | M(min) | 026μ | 040μ | 060μ | 090μ | |||

| ES 1908A | 19.3±0.3 | 8.1±0.2 | 4.8±0.2 | 5.5 | 13.9 | 4.8±0.2 | 2.3 | 4.7 | 4.01 | 0.228 | 26 | 35 | 48 | 69 |

| ES 2510A | 25.1±0.3 | 9.6±0.2 | 6.5±0.2 | 6.2 | 18.8 | 6.1±0.2 | 3 | 6.3 | 4.85 | 0.385 | 39 | 52 | 70 | 100 |

| ES 3015A | 30.1±0.3 | 15.0±0.2 | 7.1±0.2 | 9.7 | 19.5 | 7.0±0.2 | 5.1 | 6.4 | 6.56 | 0.601 | 33 | 46 | 71 | 92 |

| ES 3515A | 34.5±0.3 | 14.1±0.2 | 9.3±0.2 | 9.6 | 25.3 | 9.3±0.2 | 4.4 | 7.9 | 6.94 | 0.84 | 56 | 75 | 102 | 146 |

| ES 4117A | 40.9±0.6 | 16.5±0.3 | 12.5±0.3 | 10.4 | 28.3 | 12.5±0.3 | 6 | 7.9 | 7.75 | 1.52 | 88 | 119 | 163 | 234 |

| ES 4321A | 42.8±0.7 | 21.1±0.4 | 10.8±0.3 | 15 | 30.4 | 11.7±0.3 | 5.9 | 9.5 | 9.84 | 1.28 | 56 | 76 | 105 | 151 |

| ES 4321B | 42.8±0.7 | 21.1±0.4 | 15.4±0.3 | 15 | 30.4 | 11.7±0.3 | 5.9 | 9.5 | 9.84 | 1.83 | 80 | 108 | 150 | 217 |

| ES 4321C | 42.8±0.7 | 21.1±0.4 | 20.0±0.3 | 15 | 30.4 | 11.7±0.3 | 5.9 | 9.5 | 9.84 | 2.37 | 104 | 140 | 194 | 281 |

| ES 5528A | 54.9±0.8 | 27.6±0.4 | 20.6±0.4 | 18.5 | 37.5 | 16.8±0.4 | 8.4 | 10.3 | 12.3 | 3.5 | 116 | 157 | 219 | |

| ES 5528B | 54.9±0.8 | 27.6±0.4 | 24.6±0.4 | 18.5 | 37.5 | 16.8±0.4 | 8.4 | 10.3 | 12.3 | 4.17 | 138 | 187 | 261 | |

| ES 6533A | 65.1±1.0 | 32.5±0.5 | 27.0±0.4 | 22.2 | 44.2 | 19.7±0.4 | 10 | 12.1 | 14.7 | 5.4 | 162 | 230 | 300 | |

| ES 7228A | 72.4±1.1 | 27.9±0.5 | 19.0±0.4 | 17.8 | 52.6 | 19.1±0.4 | 9.5 | 16.9 | 13.7 | 3.68 | 130 | 173 | 236 | |

| ES 8038A | 80.0±1.2 | 38.1±0.6 | 19.8±0.4 | 28.1 | 59.3 | 19.8±0.4 | 9.9 | 19.8 | 18.5 | 3.89 | 103 | 145 | 190 | |

※ BS(Sendust Block Core), BH(HighFlux Core) and customized designs are also available.

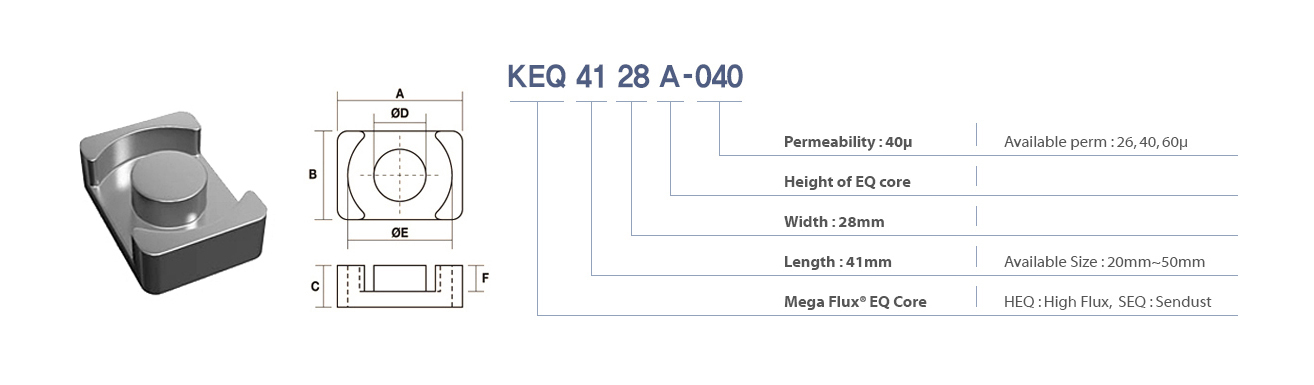

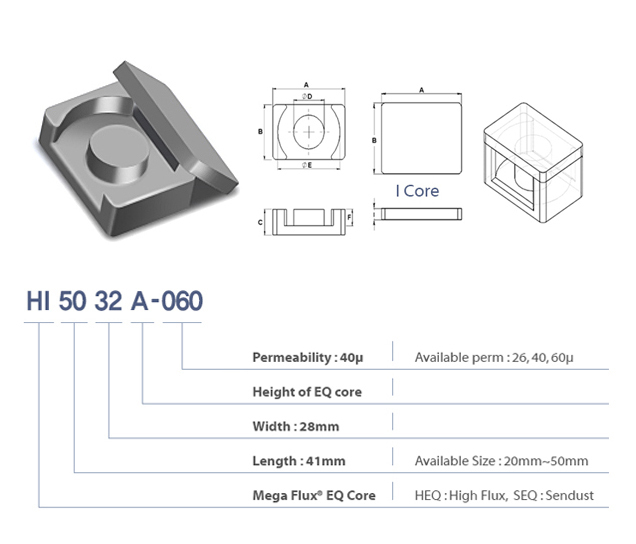

EQ Cores

It is suitable for implementing inductance with a high current capacity and easy to make inductors with a lower height than any other shaped cores. In addition, the basic advantages of the soft magnetic powder cores such as the high energy storage capacity, high temperature stability, low core loss and high operating frequency can be maintained as they are. It is also possible to select and use a core with a standardized permeability without any additional gap processing.

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | 026μ | 040μ | 060μ | |||

| KEQ 2014A | 20.5 ±0.3 | 14.0 ±0.2 | 8.1 ±0.2 | 8.8 ±0.2 | 18.0 ±0.2 | 5.7 ±0.3 | 4.52 | 0.608 | 44 | 68 | 101 |

| KEQ 2014B | 20.5 ±0.3 | 14.0 ±0.2 | 10.1 ±0.2 | 8.8 ±0.2 | 18.0 ±0.2 | 7.7 ±0.3 | 5.32 | 0.608 | 37 | 57 | 86 |

| KEQ 2619A | 26.5 ±0.3 | 19.0 ±0.2 | 10.1 ±0.2 | 12.0 ±0.2 | 22.6 ±0.3 | 6.8 ±0.3 | 5.47 | 1.198 | 72 | 110 | 165 |

| KEQ 2619B | 26.5 ±0.3 | 19.0 ±0.2 | 12.4 ±0.2 | 12.0 ±0.2 | 22.6 ±0.3 | 9.1 ±0.3 | 6.39 | 1.198 | 61 | 94 | 141 |

| KEQ 3222A | 32.0 ±0.4 | 22.0 ±0.3 | 10.3 ±0.2 | 13.5 ±0.2 | 27.6 ±0.3 | 6.6 ±0.3 | 6.03 | 1.523 | 83 | 127 | 190 |

| KEQ 3222B | 32.0 ±0.4 | 22.0 ±0.3 | 15.2 ±0.2 | 13.5 ±0.2 | 27.6 ±0.3 | 11.5 ±0.3 | 7.99 | 1.523 | 62 | 96 | 144 |

| KEQ 3626A | 36.0 ±0.5 | 26.0 ±0.3 | 17.4 ±0.3 | 14.4 ±0.2 | 32.0 ±0.4 | 13.4 ±0.3 | 9.47 | 1.808 | 62 | 96 | 144 |

| KEQ 4128A | 41.5 ±0.5 | 28.0 ±0.4 | 19.9 ±0.3 | 14.9 ±0.2 | 36.5 ±0.4 | 15.4 ±0.3 | 11.52 | 1.997 | 57 | 87 | 131 |

| KEQ 5032A | 50.0 ±0.6 | 32.0 ±0.4 | 25.0 ±0.4 | 20.0 ±0.3 | 44.0 ±0.5 | 19.5 ±0.4 | 13.34 | 3.141 | 77 | 118 | 178 |

※ KEQ (MegaFlux Cores), HEQ (High Flux Cores), SEQ (Sendust Cores) and customized designs are also available.

※ Sendust: available up to 40μ

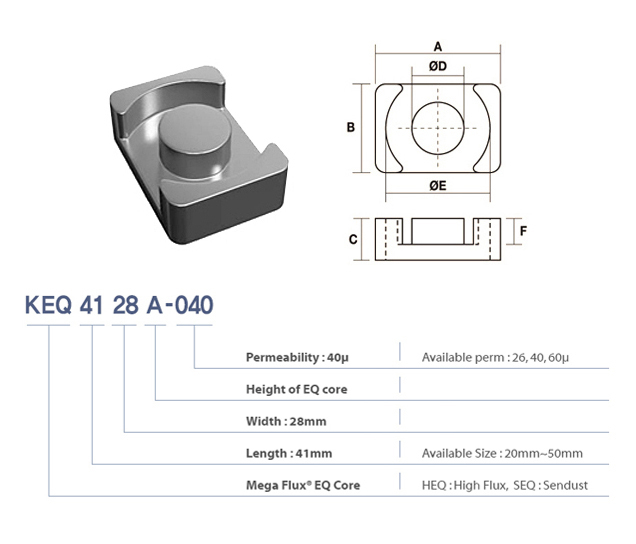

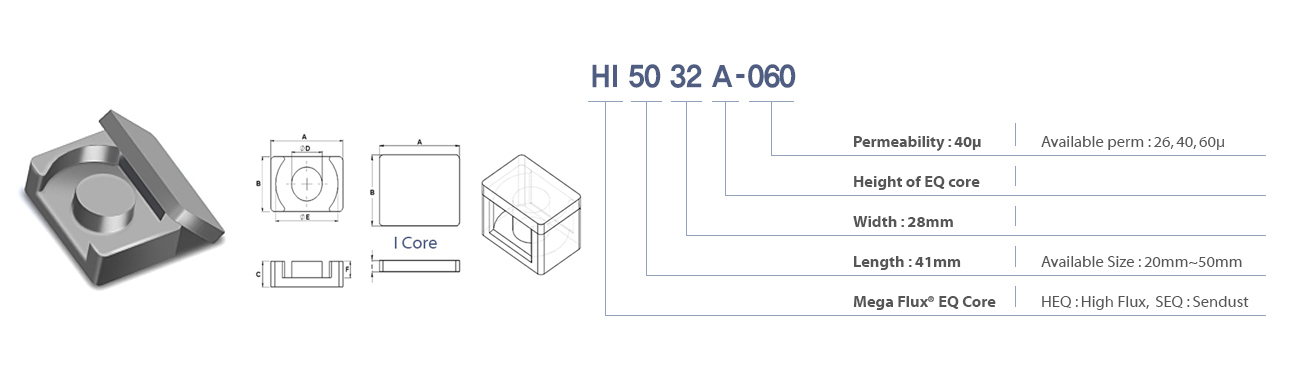

EQ+I Cores

It is suitable for realizing inductance with a high current capacity and easy to make inductors with a lower height than any other shaped cores. In addition, the basic advantages of the soft magnetic powder cores such as the high energy storage capacity, high temperature stability, low core loss and high operating frequency can be maintained as they are. It is also possible to select and use a core with standardized permeability without any additional gap processing.

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | I | 026μ | 040μ | 060μ | |||

| HEQ 2014A | 20.5 ±0.3 | 14.0 ±0.2 | 8.1 ±0.2 | 8.8 ±0.2 | 18.0 ±0.2 | 5.7 ±0.3 | 3.38 | 0.608 | 59 | 90 | 135 | |

| HI 2014A | 20.5 ±0.3 | 14.0 ±0.2 | 2.4 ±0.2 | |||||||||

| HEQ 2014B | 20.5 ±0.3 | 14.0 ±0.2 | 10.1 ±0.2 | 8.8 ±0.2 | 18.0 ±0.2 | 7.7 ±0.3 | 3.78 | 0.608 | 52 | 81 | 121 | |

| HI 2014A | 20.5 ±0.3 | 14.0 ±0.2 | 2.4 ±0.2 | |||||||||

| HEQ 2619A | 26.5 ±0.3 | 19.0 ±0.2 | 10.1 ±0.2 | 12.0 ±0.2 | 22.6 ±0.3 | 6.8 ±0.3 | 4.11 | 1.198 | 95 | 146 | 220 | |

| HI 2619A | 26.5 ±0.3 | 19.0 ±0.2 | 3.3 ±0.2 | |||||||||

| HEQ 2619B | 26.5 ±0.3 | 19.0 ±0.2 | 12.4 ±0.2 | 12.0 ±0.2 | 22.6 ±0.3 | 9.1 ±0.3 | 4.57 | 1.198 | 85 | 132 | 197 | |

| HI 2619A | 26.5 ±0.3 | 19.0 ±0.2 | 3.3 ±0.2 | |||||||||

| HEQ 3222A | 32.0 ±0.4 | 22.0 ±0.3 | 10.3 ±0.2 | 13.5 ±0.2 | 27.6 ±0.3 | 6.6 ±0.3 | 4.71 | 1.523 | 105 | 162 | 244 | |

| HI 3222A | 32.0 ±0.4 | 22.0 ±0.3 | 3.7 ±0.2 | |||||||||

| HEQ 3222B | 32.0 ±0.4 | 22.0 ±0.3 | 15.2 ±0.2 | 13.5 ±0.2 | 27.6 ±0.3 | 11.5 ±0.3 | 5.69 | 1.523 | 87 | 134 | 202 | |

| HI 3222A | 32.0 ±0.4 | 22.0 ±0.3 | 3.7 ±0.2 | |||||||||

| HEQ 3626A | 36.0 ±0.5 | 26.0 ±0.3 | 17.4 ±0.3 | 14.4 ±0.2 | 32.0 ±0.4 | 13.4 ±0.3 | 6.79 | 1.808 | 87 | 134 | 201 | |

| HI 3626A | 36.0 ±0.5 | 26.0 ±0.3 | 4.0 ±0.3 | |||||||||

| HEQ 4128A | 41.5 ±0.5 | 28.0 ±0.4 | 19.9 ±0.3 | 14.9 ±0.2 | 36.5 ±0.4 | 15.4 ±0.3 | 8.44 | 1.997 | 77 | 119 | 178 | |

| HI 4128A | 41.5 ±0.5 | 28.0 ±0.4 | 4.5 ±0.3 | |||||||||

| HEQ 5032A | 50.0 ±0.6 | 32.0 ±0.4 | 25.0 ±0.4 | 20.0 ±0.3 | 44.0 ±0.5 | 19.5 ±0.4 | 9.44 | 3.141 | 109 | 167 | 251 | |

| HI 5032A | 50.0 ±0.6 | 32.0 ±0.4 | 5.5 ±0.4 | |||||||||

※ Sendust: available up to 40μ

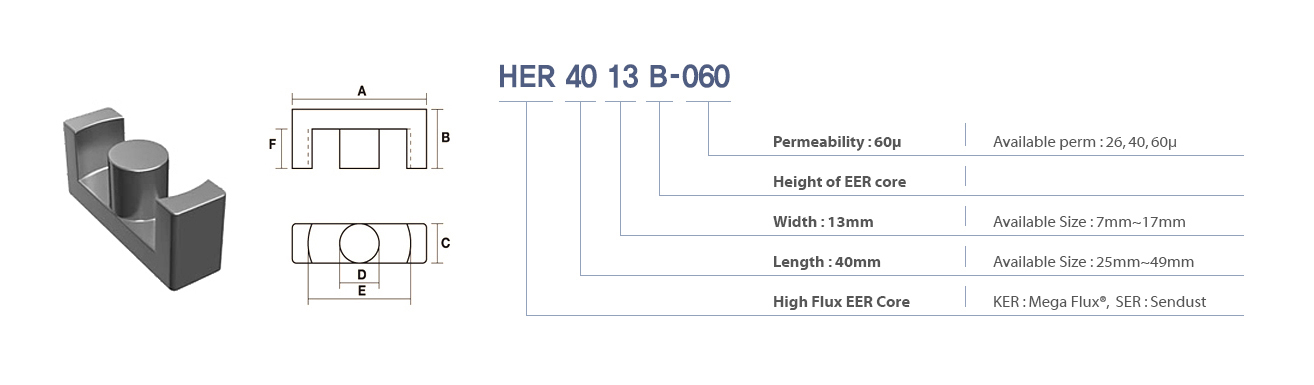

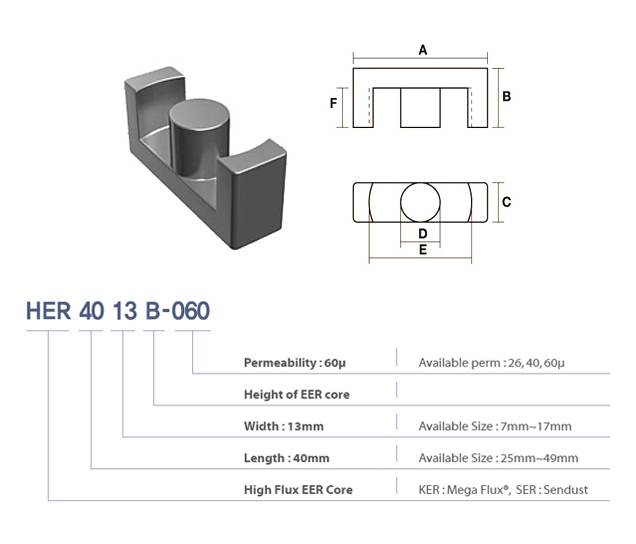

EER Cores

It is suitable for realizing inductance with a high current capacity and has the optimal core shape for the pre-winding operation. In addition, the basic advantages of the soft magnetic powder cores such as the high energy storage capacity, high temperature stability, low core loss and a high operating frequency can be maintained as they are. It is also possible to select and use a core with the standardized permeability without any additional gap processing.

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | 026μ | 040μ | 060μ | |||

| HER 2507A | 25.5±0.3 | 9.3±0.2 | 7.5±0.2 | 7.5±0.2 | 19.8±0.2 | 6.2 | 5.1 | 0.45 | 39 | 53 | 73 |

| HER 2507B | 25.5±0.3 | 11.0±0.2 | 7.5±0.2 | 7.5±0.2 | 19.8±0.2 | 7.9 | 5.78 | 0.45 | 34 | 47 | 65 |

| HER 3010A | 30.6±0.3 | 15.8±0.2 | 9.8±0.2 | 9.8±0.2 | 22.0±0.2 | 11 | 8.66 | 0.754 | 38 | 53 | 72 |

| HER 3511A | 35.0±0.4 | 15.8±0.2 | 11.3±0.2 | 11.3±0.2 | 25.6±0.3 | 9.8 | 8.3 | 1.078 | 57 | 78 | 108 |

| HER 3511B | 35.0±0.4 | 20.7±0.2 | 11.3±0.2 | 11.3±0.2 | 25.6±0.3 | 14.7 | 10.27 | 1.078 | 46 | 63 | 87 |

| HER 4013A | 40.0±0.5 | 17.4±0.3 | 13.3±0.3 | 13.3±0.3 | 29.0±0.4 | 10.4 | 9.13 | 1.491 | 72 | 99 | 135 |

| HER 4013B | 40.0±0.5 | 22.4±0.3 | 13.3±0.3 | 13.3±0.3 | 29.0±0.4 | 15.4 | 11.13 | 1.491 | 59 | 81 | 111 |

| HER 4215A | 42.0±0.6 | 22.4±0.4 | 15.5±0.4 | 15.5±0.4 | 29.4±0.5 | 15.4 | 10.64 | 2.026 | 84 | 115 | 158 |

| HER 4215B | 42.0±0.6 | 25.4±0.4 | 15.5±0.4 | 15.5±0.4 | 29.4±0.5 | 18.4 | 11.84 | 2.026 | 75 | 103 | 142 |

| HER 4917A | 49.0±0.7 | 18.8±0.5 | 17.2±0.5 | 17.2±0.5 | 36.5±0.6 | 12.2 | 9.57 | 2.353 | 99 | 136 | 185 |

| HER 4917B | 49.0±0.7 | 24.7±0.5 | 17.2±0.5 | 17.2±0.5 | 36.5±0.6 | 18.1 | 11.93 | 2.353 | 79 | 109 | 149 |

※ HER (High Flux Cores), KER (MegaFlux Cores), SER (Sendust Cores) and customized designs are also available.

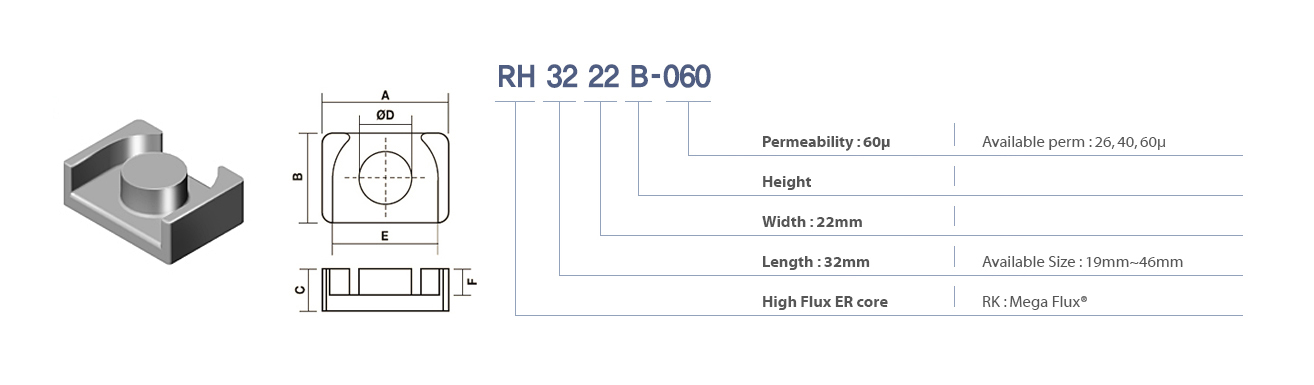

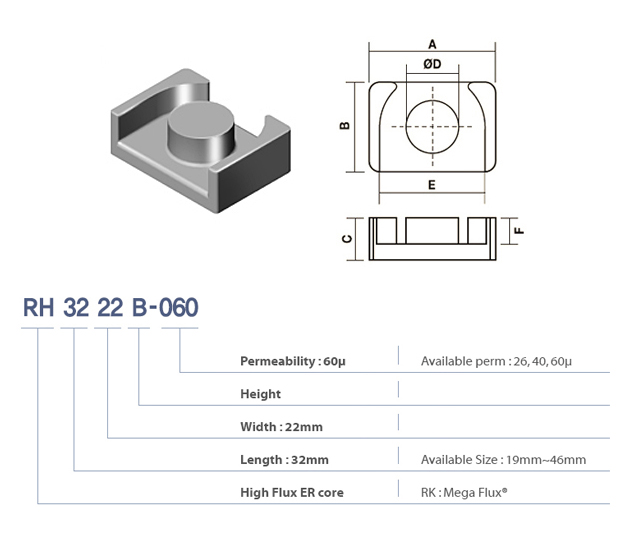

ER Cores

It is an ideal core for realizing inductors with a high current capacity and low height. It is configured for the easy positioning of the wire and allows easy and convenient circuit design and inductor mounting. In addition, the basic advantages of soft magnetic powder cores such as high energy storage capacity, high temperature stability, low core loss and a high operating frequency can be maintained as they are. It is also possible to select and use a core with the standardized permeability without any additional gap processing.

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | 026μ | 040μ | 060μ | |||

| RH1911A | 18.8±0.3 | 11.0±0.2 | 6.0±0.2 | 7.4±0.2 | 15.6±0.2 | 4.0±0.2 | 3.54 | 0.425 | 39 | 60 | 90 |

| RH2314A | 23.4±0.3 | 14.0±0.2 | 8.7±0.2 | 9.2±0.2 | 19.4±0.2 | 6.2±0.2 | 4.91 | 0.67 | 45 | 69 | 103 |

| RH2518A | 25.0±0.3 | 18.0±0.2 | 8.4±0.2 | 11.0±0.2 | 21.0±0.3 | 5.4±0.2 | 4.97 | 0.96 | 63 | 97 | 146 |

| RH2518B | 25.0±0.3 | 18.0±0.2 | 10.8±0.2 | 11.0±0.2 | 21.0±0.3 | 7.8±0.2 | 5.93 | 0.96 | 53 | 81 | 122 |

| RH3020A | 30.0±0.4 | 20.0±0.3 | 9.2±0.2 | 12.0±0.2 | 25.6±0.3 | 5.9±0.2 | 5.81 | 1.14 | 64 | 99 | 148 |

| RH3020B | 30.0±0.4 | 20.0±0.3 | 11.8±0.2 | 12.0±0.2 | 25.6±0.3 | 8.5±0.2 | 6.85 | 1.14 | 54 | 84 | 125 |

| RH3222A | 32.0±0.4 | 22.0±0.3 | 10.3±0.2 | 13.5±0.2 | 27.0±0.3 | 6.6±0.2 | 6.25 | 1.43 | 75 | 115 | 172 |

| RH3222B | 32.0±0.4 | 22.0±0.3 | 13.4±0.2 | 13.5±0.2 | 27.0±0.3 | 9.7±0.2 | 7.49 | 1.43 | 62 | 96 | 144 |

| RH3222C | 32.0±0.4 | 22.0±0.3 | 15.2±0.2 | 13.5±0.2 | 27.0±0.3 | 11.5±0.2 | 8.21 | 1.43 | 57 | 88 | 131 |

| RH3624A | 36.2±0.4 | 24.0±0.3 | 11.2±0.2 | 15.0±0.2 | 30.4±0.4 | 7.2±0.2 | 6.78 | 1.77 | 85 | 131 | 197 |

| RH3624B | 36.2±0.4 | 24.0±0.3 | 14.4±0.2 | 15.0±0.2 | 30.4±0.4 | 10.4±0.2 | 8.06 | 1.77 | 72 | 110 | 166 |

| RH4225A | 42.0±0.5 | 25.0±0.3 | 12.3±0.2 | 16.2±0.3 | 35.2±0.4 | 7.9±0.2 | 7.61 | 2.06 | 88 | 136 | 204 |

| RH4225B | 42.0±0.5 | 25.0±0.3 | 15.8±0.2 | 16.2±0.3 | 35.2±0.4 | 11.4±0.2 | 9.01 | 2.06 | 75 | 115 | 172 |

| RH4628A | 46.5±0.6 | 28.0±0.5 | 19.0±0.4 | 14.9±0.4 | 39.3±0.5 | 14.5±0.3 | 9.81 | 2.08 | 69 | 106 | 159 |

※ RH (High Flux Cores), RK (MegaFlux Cores) and customized designs are also available.

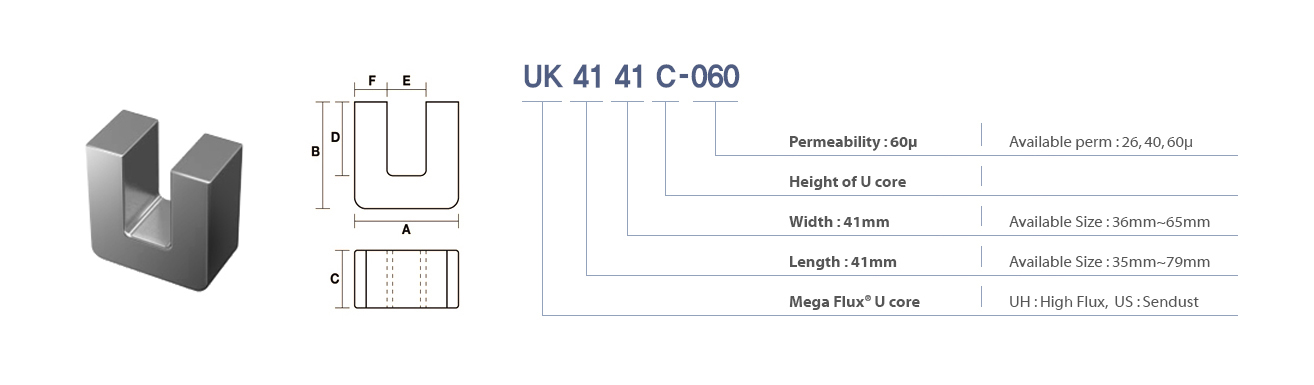

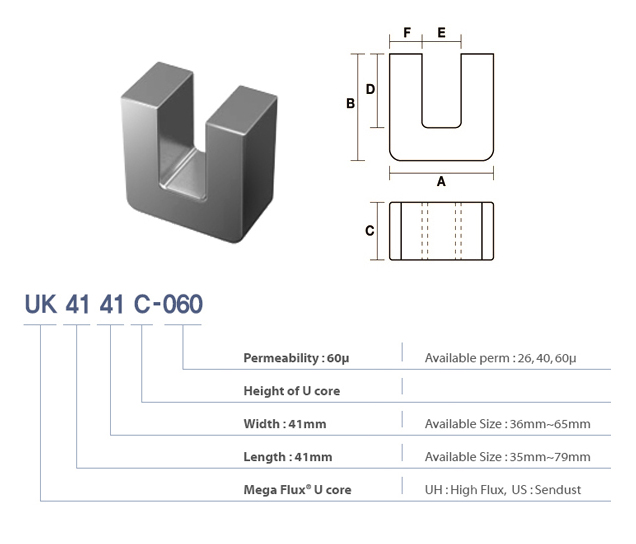

U Cores

It is suitable for inductors that require high inductance and a large current capacity. It is easy to assemble through the pre-winding operation and can minimize the space occupancy in circuits. In addition, the basic advantages of the soft magnetic powder cores such as the high energy storage capacity, high temperature stability, low core loss and the high operating frequency can be maintained as they are. It is also possible to select and use a core with the standardized permeability without any additional gap processing.

| Part No. | Dimensions(mm) | Path length (cm) | Cross Section Area (㎠) | AL value (nH/N²) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | 026μ | 040μ | 060μ | |||

| UK3536A | 35.0±0.5 | 36.0±0.5 | 20.0±0.5 | 25 | 13 | 11.0±0.3 | 16.9 | 2.2 | 43 | 65 | 98 |

| UK3536B | 35.0±0.5 | 36.0±0.5 | 25.0±0.5 | 25 | 13 | 11.0±0.3 | 16.9 | 2.75 | 53 | 82 | 123 |

| UK4141A | 41.0±0.6 | 41.0±0.6 | 20.0±0.5 | 28 | 15 | 13.0±0.3 | 19.3 | 2.6 | 44 | 68 | 102 |

| UK4141B | 41.0±0.6 | 41.0±0.6 | 25.0±0.5 | 28 | 15 | 13.0±0.3 | 19.3 | 3.25 | 55 | 85 | 127 |

| UK4141C | 41.0±0.6 | 41.0±0.6 | 30.0±0.5 | 28 | 15 | 13.0±0.3 | 19.3 | 3.9 | 66 | 102 | 152 |

| UK5251A | 52.0±0.7 | 51.0±0.7 | 25.0±0.5 | 35 | 20 | 16.0±0.4 | 24.3 | 4 | 54 | 83 | 124 |

| UK5251B | 52.0±0.7 | 51.0±0.7 | 30.0±0.5 | 35 | 20 | 16.0±0.4 | 24.3 | 4.8 | 65 | 99 | 149 |

| UK6361A | 63.0±0.8 | 60.5±0.8 | 30.0±0.5 | 41.5 | 25..0 | 19.0±0.4 | 29.1 | 5.7 | 64 | 98 | 148 |

| UK6361B | 63.0±0.8 | 60.5±0.8 | 35.0±0.5 | 41.5 | 25 | 19.0±0.4 | 29.1 | 6.65 | 75 | 115 | 172 |

| UK7965A | 79.0±1.0 | 64.5±1.0 | 30.0±0.5 | 42.5 | 35 | 22.0±0.5 | 32.6 | 6.6 | 66 | 102 | 153 |

| UK7965B | 79.0±1.0 | 64.5±1.0 | 35.0±0.5 | 42.5 | 35 | 22.0±0.5 | 32.6 | 7.7 | 77 | 119 | 178 |

※ UH(High Flux U Core), US(SendustU Core) and customized designs are also available.

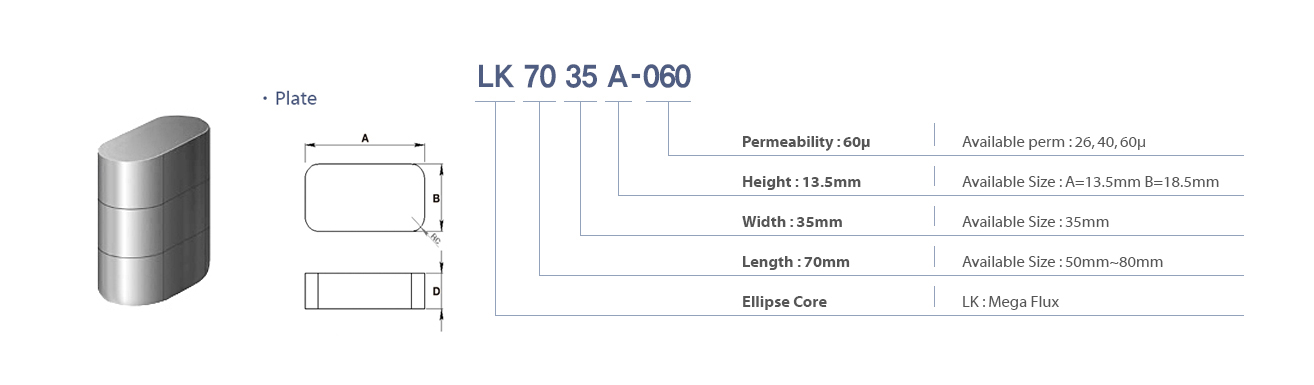

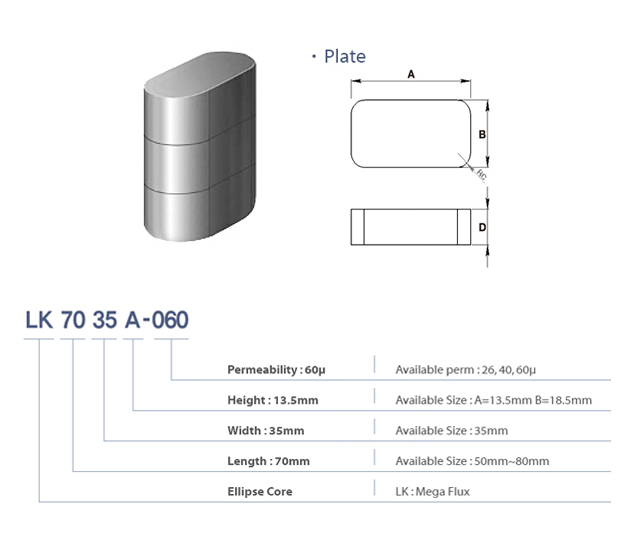

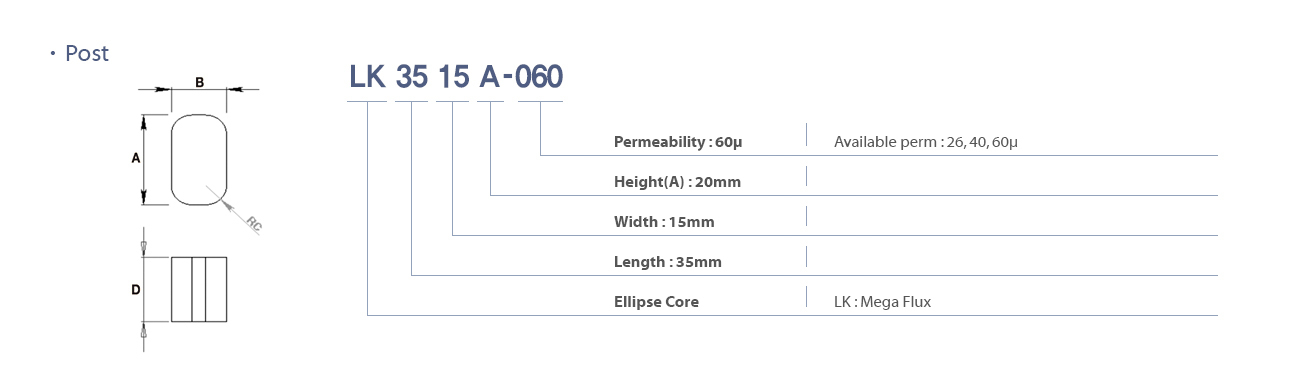

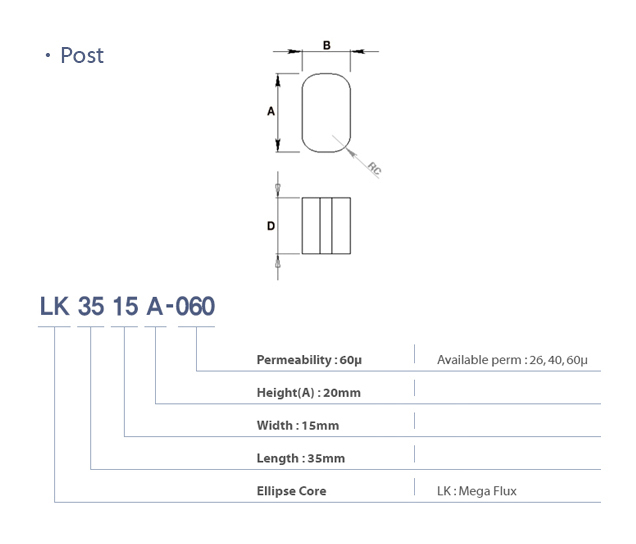

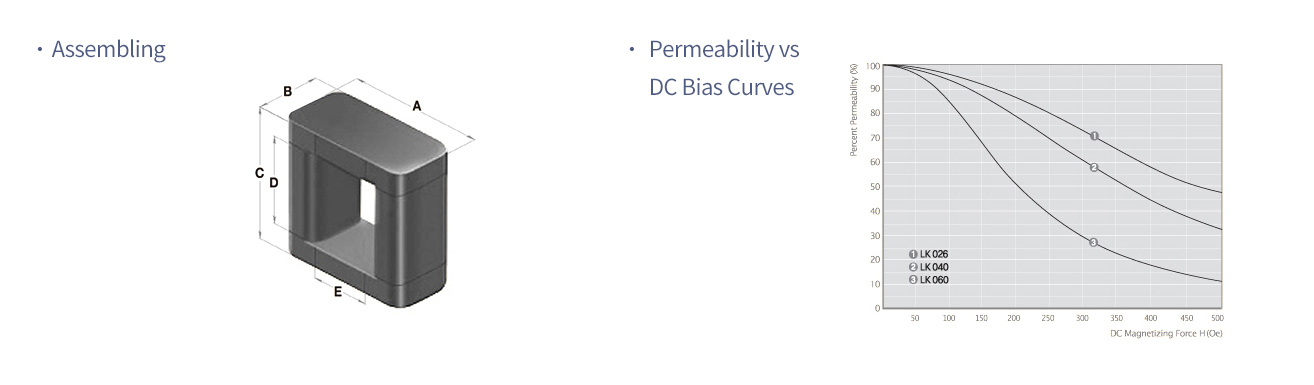

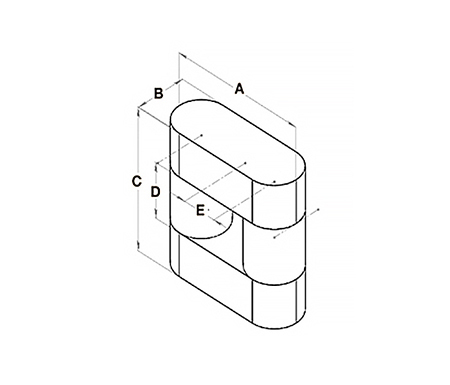

Ellipse Cores

Inductors in various sizes and properties can be designed flexibly through the easy mixing and assembly with block cores, etc. In particular, when used as a core in the winding unit, it is possible to implement high-efficiency large-scale inductors by minimizing the winding usage, insulation breakdown in the bent area and DC resistance of the windings through an optimized shape. In addition, the basic advantages of the soft magnetic powder cores such as the high energy storage capacity, high temperature stability, low core loss and high operating frequency can be maintained as they are.

| Part No. | Dimensions (mm) | Cross Section Area (㎠) | Post | |||

|---|---|---|---|---|---|---|

| A Length |

B Width |

RC Radius |

D Height |

|||

| LK5035A | 50.5±0.5 | 35.3±0.3 | 7.5±0.2 | 13.5±0.2 | 4.77 | LK3515A LK3515B LK3520A LK3520B |

| LK5035B | 50.5±0.5 | 35.3±0.3 | 7.5±0.2 | 18.5±0.2 | 6.52 | |

| LK6035A | 60.5±0.5 | 35.3±0.3 | 7.5±0.2 | 13.5±0.2 | 4.77 | |

| LK6035B | 60.5±0.5 | 35.3±0.3 | 7.5±0.2 | 18.5±0.2 | 6.52 | |

| LK7035A | 70.5±0.5 | 35.3±0.3 | 7.5±0.2 | 13.5±0.2 | 4.77 | |

| LK7035B | 70.5±0.5 | 35.3±0.3 | 7.5±0.2 | 18.5±0.2 | 6.52 | |

| LK8035A | 80.5±0.5 | 35.3±0.3 | 7.5±0.2 | 13.5±0.2 | 4.77 | |

| LK8035B | 80.5±0.5 | 35.3±0.3 | 7.5±0.2 | 18.5±0.2 | 6.52 | |

※LS(Sendust Ellipse Core), LH(High Flux Ellipse Core) and customized designs are also available.

| Part No. | Dimensions (mm) | Cross Section Area (㎠) | Plate | |||

|---|---|---|---|---|---|---|

| A Length |

B Width |

RC Radius |

D Height |

|||

| LK3515A | 35.3 ±0.3 | 15.2 ±0.2 | 7.5 ±0.2 | 20.0 ±0.2 | 4.77 | LK5035A LK6035A LK7035A |

| LK3515B | 35.3 ±0.3 | 15.2 ±0.2 | 7.5 ±0.2 | 25.0 ±0.2 | 4.77 | |

| LK3520A | 35.3 ±0.3 | 20.2 ±0.2 | 7.5 ±0.2 | 20.0 ±0.2 | 6.52 | |

| LK3520B | 35.3 ±0.3 | 20.2 ±0.2 | 7.5 ±0.2 | 25.0 ±0.2 | 6.52 | |

| Part No. | Post | Dimensions (mm) | Path Length (cm) |

Cross Section Area (㎠) |

Window Area (㎠) |

AL value (nH/N2) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part No. | 1 LEG STACK |

A Length |

B Width |

C Height |

D Inner Height |

E Inner Length |

026μ | 040μ | 060μ | ||||

| LK5035A | LK3515A | 2 | 50.5±0.5 | 35.3±0.3 | 67.0±0.5 | 40.0±0.4 | 20.0±0.4 | 16.47 | 4.77 | 8 | 113 | 146 | 218 |

| LK3515B | 2 | 50.5±0.5 | 35.3±0.3 | 77.0±0.5 | 50.0±0.4 | 20.0±0.4 | 18.47 | 4.77 | 10 | 101 | 130 | 195 | |

| LK3515A | 3 | 50.5±0.5 | 35.3±0.3 | 87.0±0.5 | 60.0±0.4 | 20.0±0.4 | 20.47 | 4.77 | 12 | 91 | 117 | 176 | |

| LK5035B | LK3520A | 2 | 50.5±0.5 | 35.3±0.3 | 77.0±0.5 | 40.0±0.4 | 10.0±0.4 | 16.04 | 6.52 | 4 | 158 | 204 | 306 |

| LK3520B | 2 | 50.5±0.5 | 35.3±0.3 | 87.0±0.5 | 50.0±0.4 | 10.0±0.4 | 18.04 | 6.52 | 5 | 141 | 182 | 273 | |

| LK3520A | 3 | 50.5±0.5 | 35.3±0.3 | 97.0±0.5 | 60.0±0.4 | 10.0±0.4 | 20.04 | 6.52 | 6 | 127 | 164 | 245 | |

| LK6035A | LK3515A | 2 | 60.5±0.5 | 35.3±0.3 | 67.0±0.5 | 40.0±0.4 | 30.0±0.4 | 18.47 | 4.77 | 12 | 101 | 130 | 195 |

| LK3515B | 2 | 60.5±0.5 | 35.3±0.3 | 77.0±0.5 | 50.0±0.4 | 30.0±0.4 | 20.47 | 4.77 | 15 | 91 | 117 | 176 | |

| LK3515A | 3 | 60.5±0.5 | 35.3±0.3 | 87.0±0.5 | 60.0±0.4 | 30.0±0.4 | 22.47 | 4.77 | 18 | 83 | 107 | 160 | |

| LK6035B | LK3520A | 2 | 60.5±0.5 | 35.3±0.3 | 77.0±0.5 | 40.0±0.4 | 20.0±0.4 | 18.04 | 6.52 | 8 | 141 | 182 | 273 |

| LK3520B | 2 | 60.5±0.5 | 35.3±0.3 | 87.0±0.5 | 50.0±0.4 | 20.0±0.4 | 20.04 | 6.52 | 10 | 127 | 164 | 245 | |

| LK3520A | 3 | 60.5±0.5 | 35.3±0.3 | 97.0±0.5 | 60.0±0.4 | 20.0±0.4 | 22.04 | 6.52 | 12 | 115 | 149 | 223 | |

| LK7035A | LK3515A | 2 | 70.5±0.5 | 35.3±0.3 | 67.0±0.5 | 40.0±0.4 | 40.0±0.4 | 20.47 | 4.77 | 16 | 91 | 117 | 176 |

| LK3515B | 2 | 70.5±0.5 | 35.3±0.3 | 77.0±0.5 | 50.0±0.4 | 40.0±0.4 | 22.47 | 4.77 | 20 | 83 | 107 | 160 | |

| LK3515A | 3 | 70.5±0.5 | 35.3±0.3 | 87.0±0.5 | 60.0±0.4 | 40.0±0.4 | 24.47 | 4.77 | 24 | 76 | 98 | 147 | |

| LK7035B | LK3520A | 2 | 70.5±0.5 | 35.3±0.3 | 77.0±0.5 | 40.0±0.4 | 30.0±0.4 | 20.04 | 6.52 | 12 | 127 | 164 | 245 |

| LK3520B | 2 | 70.5±0.5 | 35.3±0.3 | 87.0±0.5 | 50.0±0.4 | 30.0±0.4 | 22.04 | 6.52 | 15 | 115 | 149 | 223 | |

| LK3520A | 3 | 70.5±0.5 | 35.3±0.3 | 97.0±0.5 | 60.0±0.4 | 30.0±0.4 | 24.04 | 6.52 | 18 | 106 | 136 | 204 | |

| LK8035A | LK3515A | 2 | 80.5±0.5 | 35.3±0.3 | 67.0±0.5 | 40.0±0.4 | 50.0±0.4 | 22.47 | 4.77 | 16 | 83 | 107 | 160 |

| LK3515B | 2 | 80.5±0.5 | 35.3±0.3 | 77.0±0.5 | 50.0±0.4 | 50.0±0.4 | 24.47 | 4.77 | 20 | 76 | 98 | 147 | |

| LK3515A | 3 | 80.5±0.5 | 35.3±0.3 | 87.0±0.5 | 60.0±0.4 | 50.0±0.4 | 26.47 | 4.77 | 24 | 70 | 91 | 136 | |

| LK8035B | LK3520A | 2 | 80.5±0.5 | 35.3±0.3 | 77.0±0.5 | 40.0±0.4 | 40.0±0.4 | 22.04 | 6.52 | 12 | 115 | 149 | 223 |

| LK3520B | 2 | 80.5±0.5 | 35.3±0.3 | 87.0±0.5 | 50.0±0.4 | 40.0±0.4 | 24.04 | 6.52 | 15 | 106 | 136 | 204 | |

| LK3520A | 3 | 80.5±0.5 | 35.3±0.3 | 97.0±0.5 | 60.0±0.4 | 40.0±0.4 | 26.04 | 6.52 | 18 | 98 | 126 | 189 | |

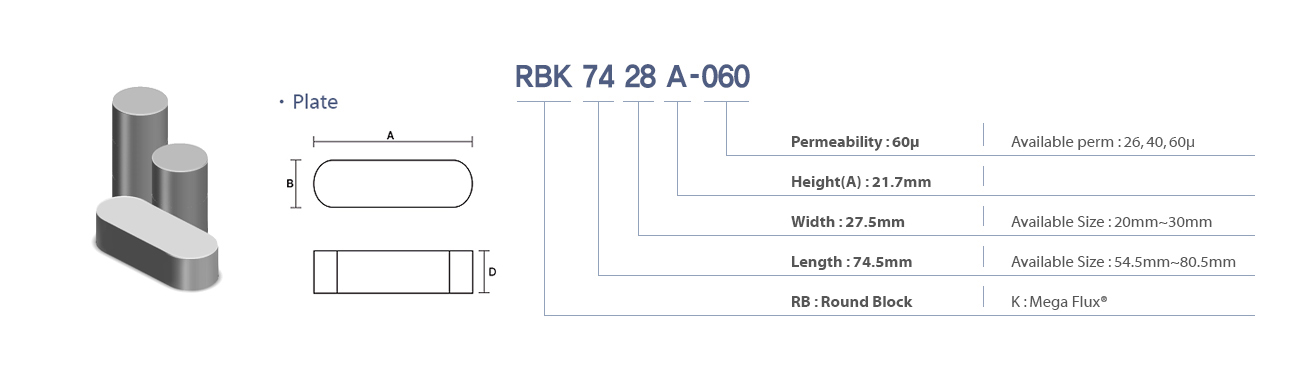

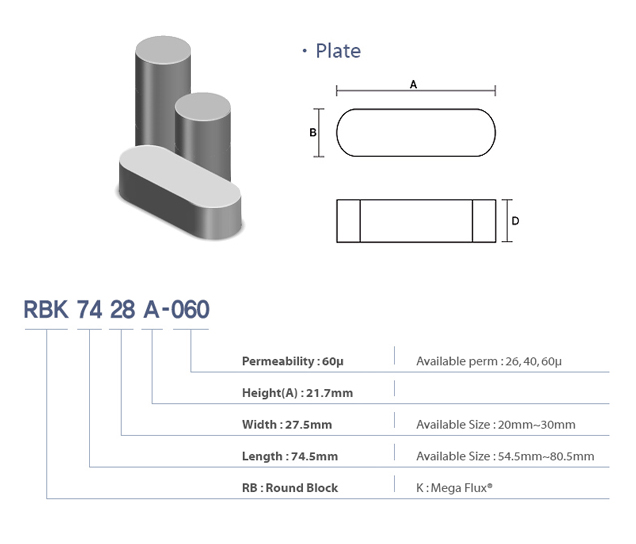

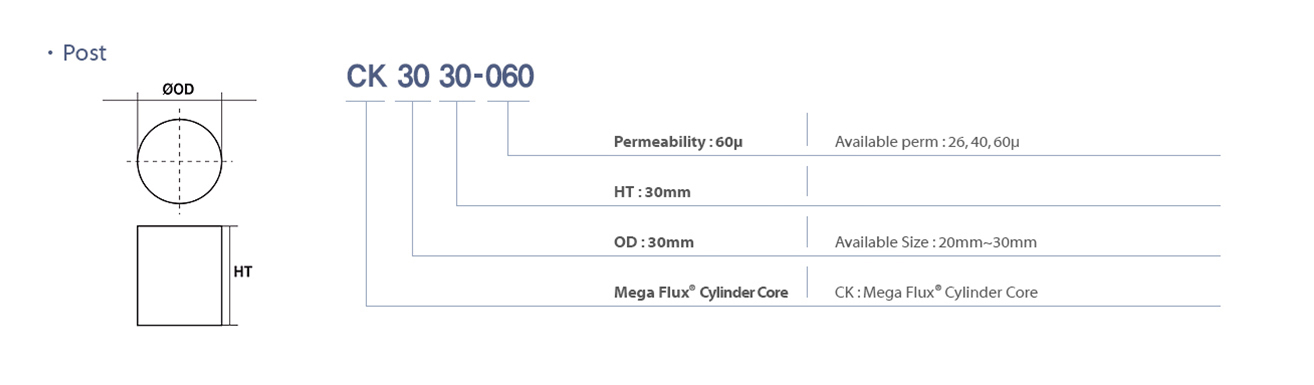

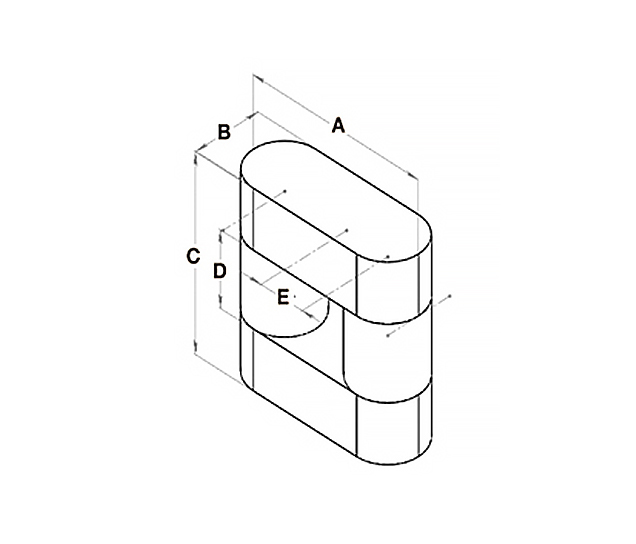

Round Block + Cylinder Cores

Inductors that come in various sizes and properties can be designed flexibly through the easy mixing and assembly with block cores, etc. In particular, the round shape of the cores enables high-efficiency large-scale inductors to be realized by minimizing the use of the windings, insulation breakdown of the bending area, DC resistance of the windings. In addition, the basic advantages of the soft magnetic powder cores such as high energy storage capacity, high temperature stability, low core loss and high operating frequency can be maintained as they are.

| Part No. | Dimensions (mm) | Cross Section Area (㎠) |

Post | |||

|---|---|---|---|---|---|---|

| A Length |

B Width |

RC Radius |

D Height |

|||

| RBK5420A | 54.5±0.5 | 20.2±0.3 | 10.0±0.2 | 15.7±0.2 | 3.14 | CK2020 |

| RBK6424A | 64.5±0.5 | 24.2±0.3 | 12.0±0.2 | 18.8±0.2 | 4.52 | CK2424 |

| RBK6725A | 67.5±0.5 | 25.2±0.3 | 12.5±0.2 | 19.6±0.2 | 4.91 | CK2525 |

| RBK7428A | 74.5±0.5 | 27.5±0.3 | 13.7±0.2 | 21.7±0.2 | 6 | CK2828 |

| RBK8030A | 80.5±0.5 | 30.2±0.3 | 15.0±0.2 | 23.5±0.2 | 7.07 | CK3030 |

| Part No. | Dimensions (mm) | 1Turn length (mm) |

Cross Section Area (㎠) |

Plate | |

|---|---|---|---|---|---|

| OD | HT | ||||

| CK2020 | 20.2±0.3 | 20.2±0.2 | 62.8 | 3.14 | RBK5420-15 |

| CK2424 | 24.2±0.3 | 24.2±0.2 | 75.4 | 4.52 | RBK6424-18 |

| CK2525 | 25.2±0.3 | 25.2±0.2 | 78.5 | 4.91 | RBK6725-19 |

| CK2828 | 27.5±0.3 | 28.0±0.2 | 86.4 | 6 | RBK7428-21 |

| CK3030 | 30.2±0.3 | 30.0±0.2 | 94.2 | 7.07 | RBK8030-23 |

| Part No. | Post | Dimensions (mm) | Path Length (cm) |

Cross Section Area (㎠) |

Window Area (㎠) |

AL value (nH/N2) ±12% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part No. | 1 LEG STACK |

A Length |

B Width |

C Height |

D Inner Height |

E Inner Length |

026μ | 040μ | 060μ | ||||

| RBK5420A | CK2020 | 1 | 54 | 20 | 51.4 | 20 | 14 | 12.41 | 3.14 | 2.8 | 99 | 127 | 191 |

| 2 | 54 | 20 | 71.4 | 40 | 14 | 16.41 | 3.14 | 5.6 | 75 | 96 | 144 | ||

| 3 | 54 | 20 | 91.4 | 60 | 14 | 20.41 | 3.14 | 8.4 | 60 | 77 | 116 | ||

| RBK6424A | CK2424 | 1 | 64 | 24 | 61.6 | 24 | 16 | 14.72 | 4.52 | 3.84 | 120 | 154 | 232 |

| 2 | 64 | 24 | 85.6 | 48 | 16 | 19.52 | 4.52 | 7.68 | 90 | 116 | 175 | ||

| 3 | 64 | 24 | 109.6 | 72 | 16 | 24.32 | 4.52 | 11.52 | 72 | 93 | 140 | ||

| RBK6725A | CK2525 | 1 | 67 | 25 | 64.2 | 25 | 17 | 15.41 | 4.91 | 4.25 | 124 | 160 | 240 |

| 2 | 67 | 25 | 89.2 | 50 | 17 | 20.41 | 4.91 | 8.5 | 94 | 121 | 181 | ||

| 3 | 67 | 25 | 114.2 | 75 | 17 | 25.41 | 4.91 | 12.75 | 75 | 97 | 146 | ||

| RBK7428A | CK2828 | 1 | 74 | 27.5 | 71.4 | 28 | 19 | 17.13 | 6 | 5.32 | 136 | 176 | 264 |

| 2 | 74 | 27.5 | 99.4 | 56 | 19 | 22.73 | 6 | 10.64 | 103 | 133 | 199 | ||

| 3 | 74 | 27.5 | 127.4 | 84 | 19 | 28.33 | 6 | 15.96 | 83 | 106 | 160 | ||

| RBK8030A | CK3030 | 1 | 80 | 30 | 77 | 30 | 20 | 18.4 | 7.07 | 6 | 150 | 193 | 290 |

| 2 | 80 | 30 | 107 | 60 | 20 | 24.4 | 7.07 | 12 | 113 | 146 | 218 | ||

| 3 | 80 | 30 | 137 | 90 | 20 | 30.4 | 7.07 | 18 | 91 | 117 | 175 | ||

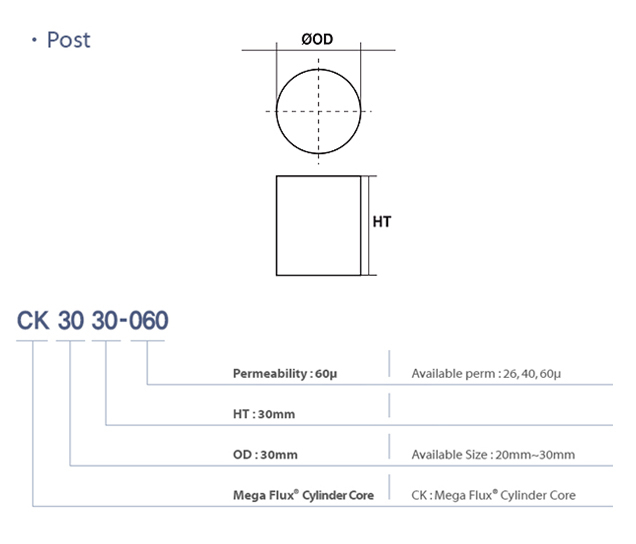

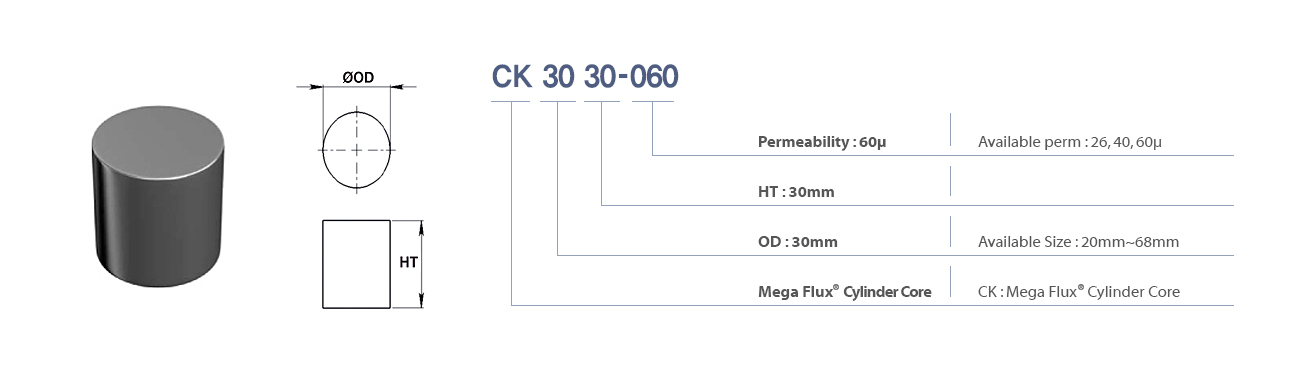

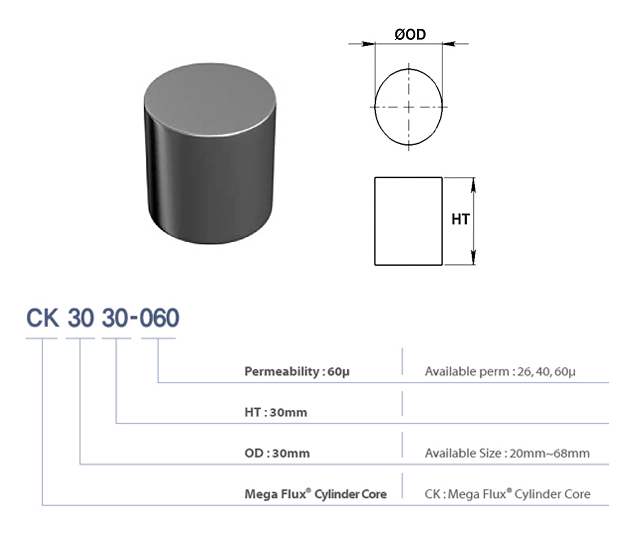

Cylinder Cores

It can be used in combination with the block cores, etc., and inductors in various sizes and properties can be flexibly designed through an easy assembly. This core enables high-efficiency large-scale inductors to be realized by minimizing the use of the windings, insulation breakdown of the bending area, DC resistance of the windings due to its tight engagement with the winding unit. In addition, the basic advantages of the soft magnetic powder cores such as the high energy storage capacity, high temperature stability, low core loss and high operating frequency can be maintained as they are.

| Part No. | Dimensions (mm) | Path Length (mm) |

Cross Section Area (㎠) |

||||

|---|---|---|---|---|---|---|---|

| OD | HT | 26μ | 040μ | 060μ | |||

| CK2020 | 20.2 ±0.2 | 20.0 ±0.2 | 3.14 | ||||

| CK2424 | 24.0 ±0.2 | 24.0 ±0.2 | 4.5 | ||||

| CK2525 | 25.0 ±0.2 | 25.0 ±0.2 | 4.91 | ||||

| CK2825 | 27.6 ±0.3 | 25.0 ±0.2 | 6 | ||||

| CK2830 | 27.6 ±0.3 | 30.0 ±0.2 | 6 | ||||

| CK3026 | 30.0 ±0.5 | 26.0 ±0.2 | 7.07 | ||||

| CK3030 | 30.0 ±0.5 | 30.0 ±0.2 | 7.07 | ||||

| CK3035 | 30.0 ±0.5 | 34.7 ±0.2 | 7.07 | ||||

| CK3530 | 35.0 ±0.5 | 30.0 ±0.2 | 9.62 | ||||

| CK3735 | 37.0 ±0.5 | 35.25 ±0.2 | 10.75 | ||||

| CK4030 | 40.0 ±0.6 | 30.0 ±0.3 | 12.56 | ||||

| CK4230 | 42.0 ±0.6 | 30.0 ±0.3 | 13.85 | ||||

| CK4630 | 46.0 ±0.6 | 30.0 ±0.3 | 16.61 | ||||

| CK5030 | 50.0 ±0.7 | 30.0 ±0.4 | 19.63 | ||||

| CK5530 | 55.0 ±0.7 | 30.0 ±0.4 | 23.76 | ||||

| CK6030 | 60.0 ±0.8 | 30.0 ±0.5 | 28.27 | ||||

| CK6330 | 63.0 ±0.8 | 30.0 ±0.5 | 31.17 | ||||

| CK6830 | 68.0 ±0.8 | 30.0 ±0.5 | 36.31 | ||||

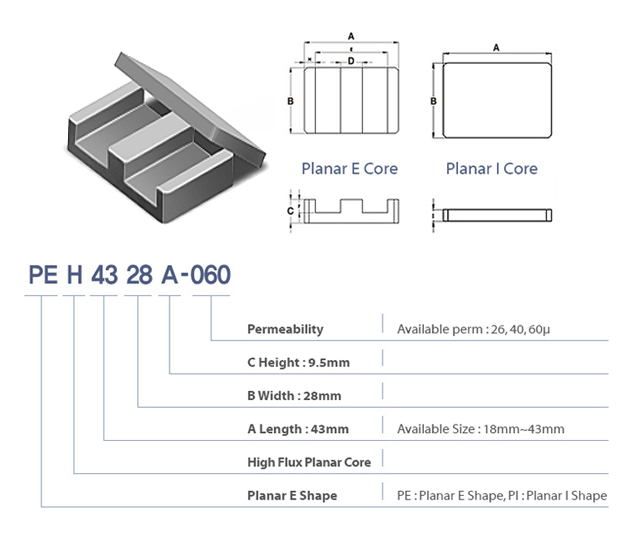

Planar E + I Cores

Thanks to its structural advantages of thin thickness, it provides the optimal solutions for small inductors with a large current. It has almost no leakage of the magnetic flux and has an excellent DC Bias characteristic, high temperature stability and high energy storage capability.

| Part NO. | Dimensions | Path Length (cm) |

Cross Section Area |

AL value (nH/n2)±12% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | F(mm) | H, I(mm) | 026μ | 040μ | 060μ | |||

| PEH 1810A | 18.0±0.3 | 10.0±0.2 | 4.0±0.2 | 4.0±0.2 | 14.0±0.2 | 2.0±0.3 | 2.0±0.2 | 2.03 | 0.394 | 63 | 98 | 146 |

| PIH 1810A | 18.0±0.3 | 10.0±0.2 | 2.0±0.2 | |||||||||

| PEH 2216A | 21.8±0.3 | 15.8±0.2 | 5.7±0.2 | 5.0±0.2 | 16.8±0.2 | 3.2±0.3 | 2.5±0.2 | 2.61 | 0.78 | 98 | 150 | 225 |

| PIH 2216A | 21.8±0.3 | 15.8±0.2 | 2.5±0.2 | |||||||||

| PEH 3220A | 31.8±0.3 | 20.3±0.2 | 6.4±0.2 | 6.4±0.2 | 25.4±0.3 | 3.2±0.3 | 3.2±0.2 | 3.55 | 1.283 | 118 | 182 | 272 |

| PIH 3220A | 31.8±0.3 | 20.3±0.2 | 3.2±0.2 | |||||||||

| PEH 3825A | 38.0±0.3 | 25.4±0.2 | 8.2±0.2 | 7.6±0.2 | 30.4±0.3 | 4.4±0.3 | 3.8±0.2 | 4.35 | 1.906 | 143 | 220 | 330 |

| PIH 3825A | 38.0±0.3 | 25.4±0.2 | 3.8±0.2 | |||||||||

| PEH 4328A | 43.2±0.4 | 27.9±0.3 | 9.5±0.2 | 8.2±0.2 | 35.0±0.3 | 5.4±0.3 | 4.1±0.2 | 5.05 | 2.257 | 146 | 225 | 337 |

| PIH 4328A | 43.2±0.4 | 27.9±0.3 | 4.1±0.2 | |||||||||